by Donnie Hurt | Apr 1, 2021 | OPERATIONS

MEASURE ONCE, CUT TWICE Yes, we’ve all made that mistake, measure once and you better hope you cut it long, so the second cut will be on spec. Otherwise you’ve ruined the work. The proper phrase, measure twice… seems to apply to many things we do around the shop. ...

by Donnie Hurt | Apr 1, 2021 | BLOCK WORK

A DIFFERENT CAM BEARING FIT Most if not all OEM blocks were fitted with semi-finished cam bearings and then the I.D.”s were bored in place. Many suffer from poor factory size issues. This situation can lead to tight or no bearing clearance when finished cam bearings...

by Donnie Hurt | Apr 1, 2021 | DISASSEMBLY & CLEANING

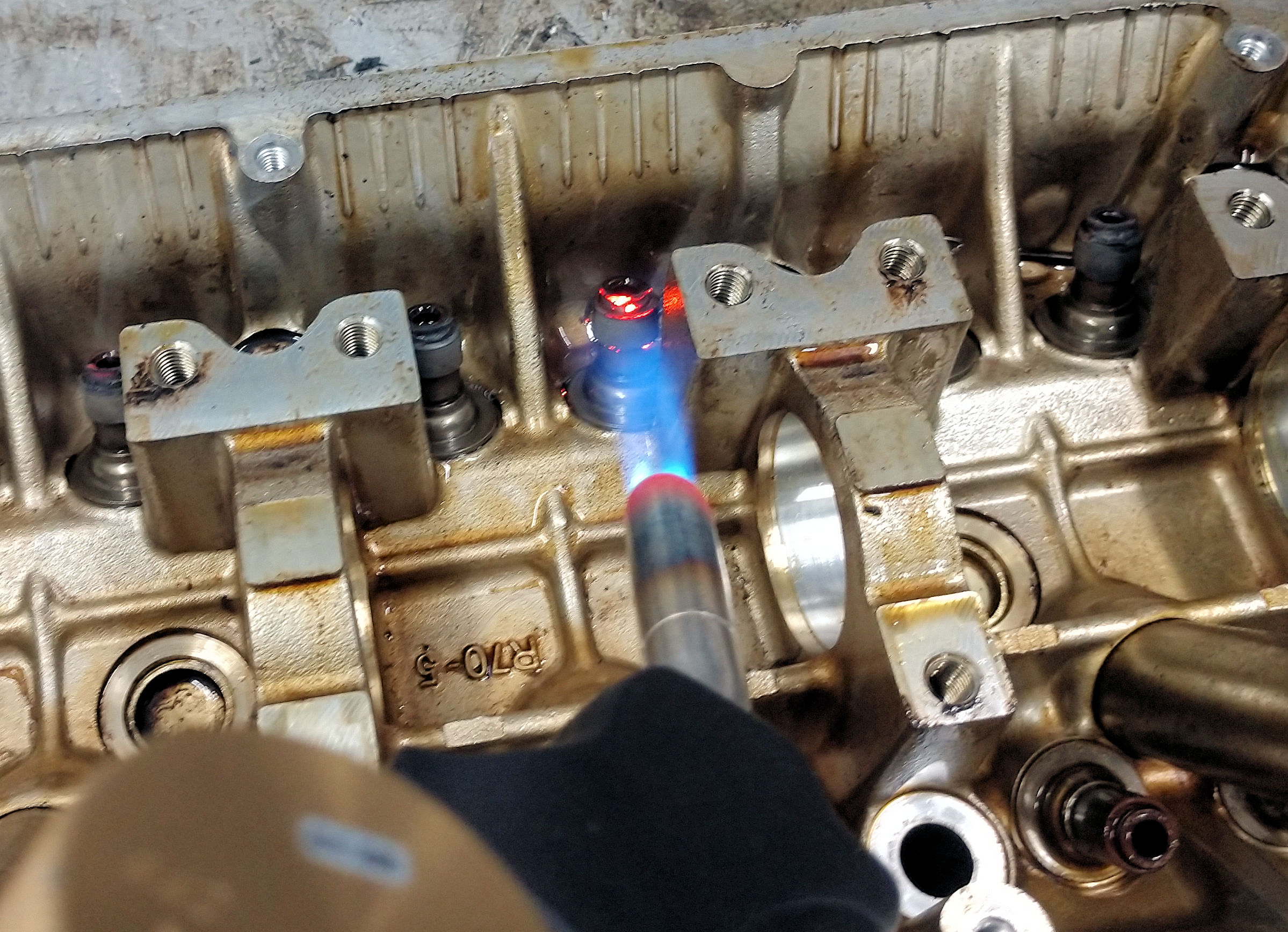

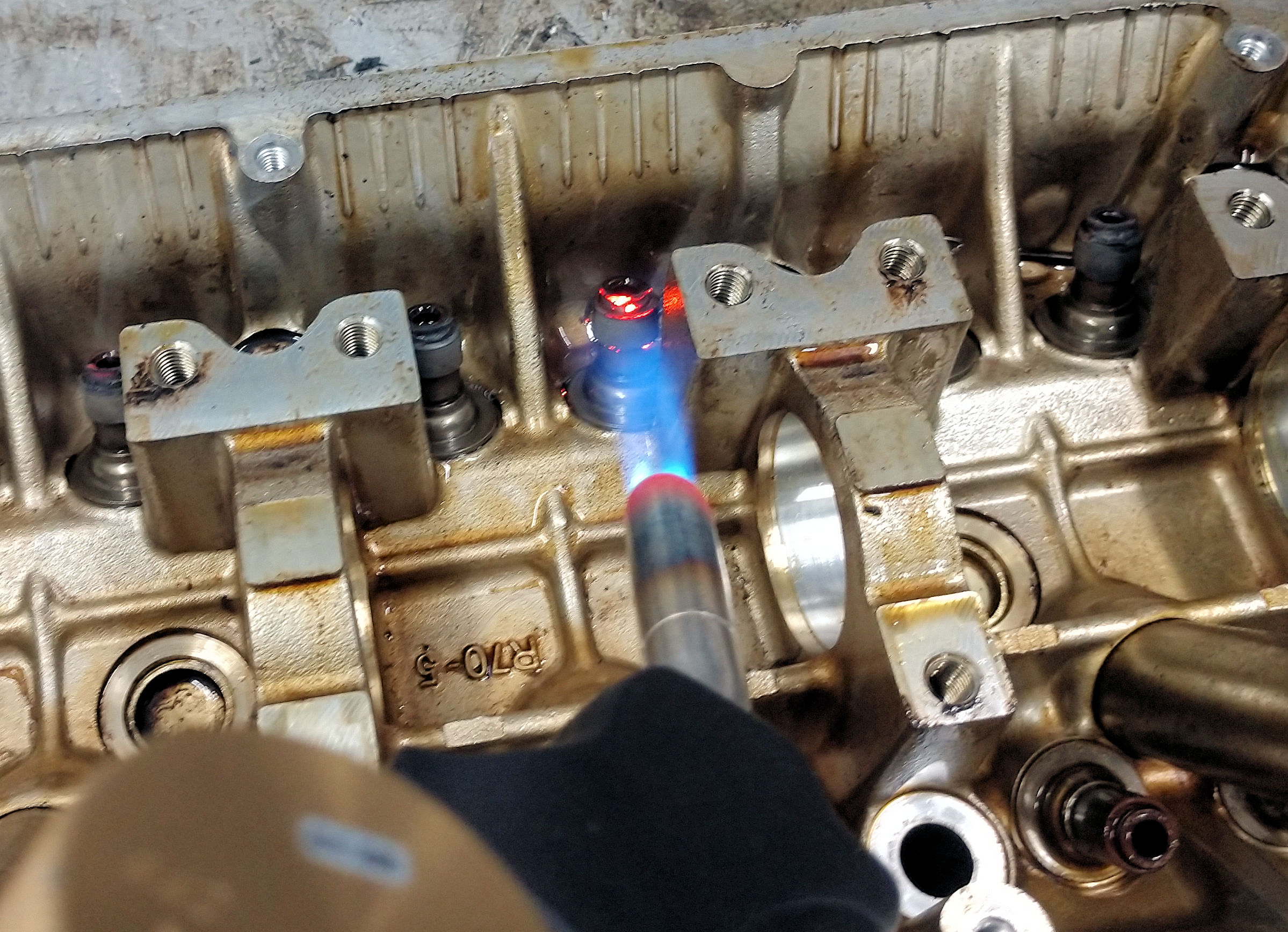

ANOTHER SILLY HEAT TRICK We all heat our oil plugs, studs and bolts to free them up. I found another heat solution, removing stubborn valve seals. I just warm them up with a propane torch to soften the rubber and they pull right off. This works great! Randy Torvinen...

by Donnie Hurt | Mar 1, 2021 | ASSEMBLY

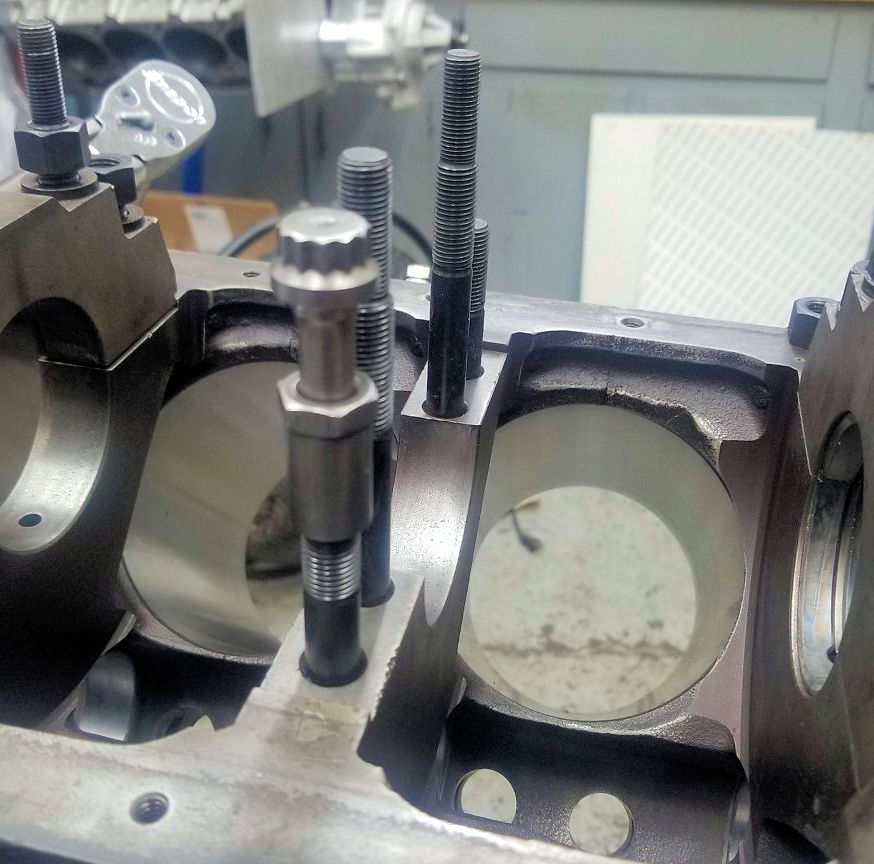

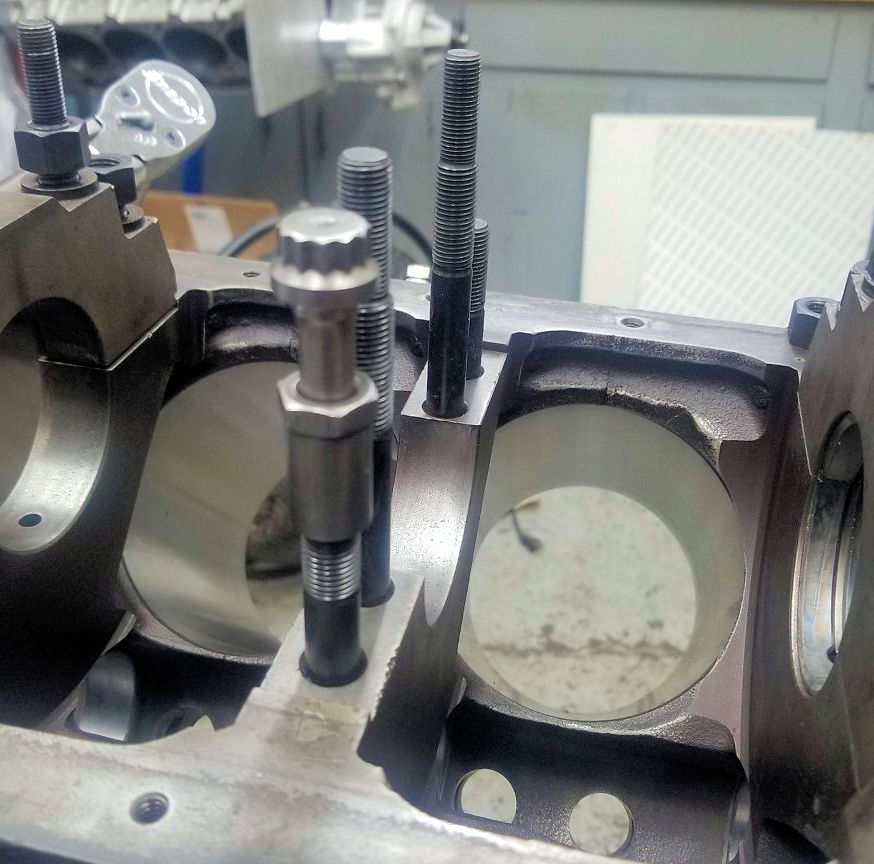

STUD INSTALLER We use an old roller rocker arm adjuster nut and put a used rod bolt in place of the Allen jam bolt. I use this assembly to install main and head studs when they do not have a hex in them. Terry Dowker Dowker Engines Charlotte, MI MARCH,...

by Donnie Hurt | Mar 1, 2021 | BLOCK WORK

CAP MILLING I like to mill my main caps instead of grinding them, when possible. The milling process gets them very flat with accurate stock removal. This “Vice Adjuster” makes it quick to set tilt and I use a precision level along with an indicator to dial-in side to...