by Donnie Hurt | Dec 1, 2020 | BLOCK WORK

NUMBER YOUR STONES When changing stones on your line hone from cast iron blocks to aluminum blocks with billet caps, I take an engraving tool and engrave a #1 on my mandrels to mark where to start and engraved the stone position and mandrel size into each stone. It...

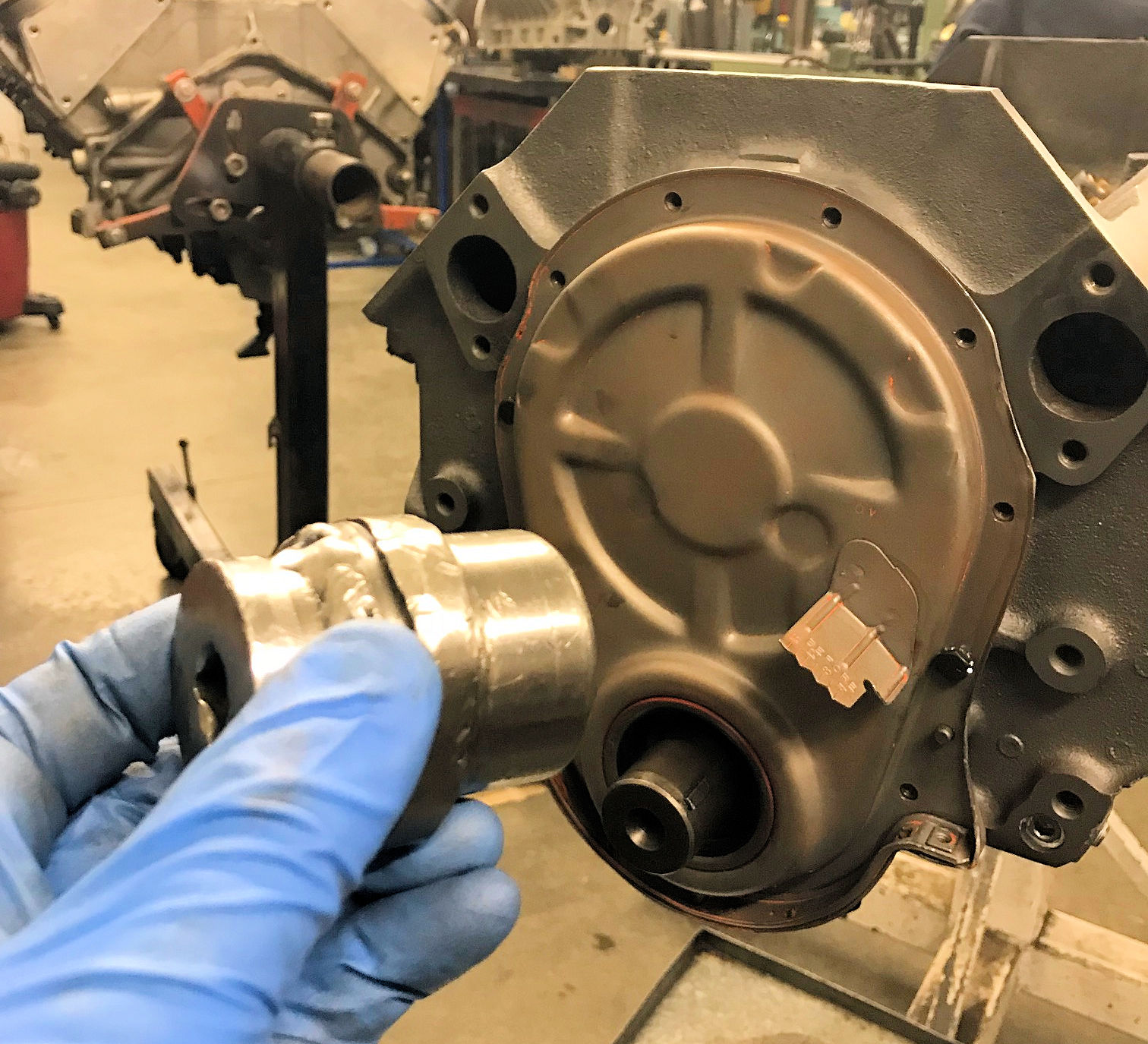

by Donnie Hurt | Dec 1, 2020 | ASSEMBLY

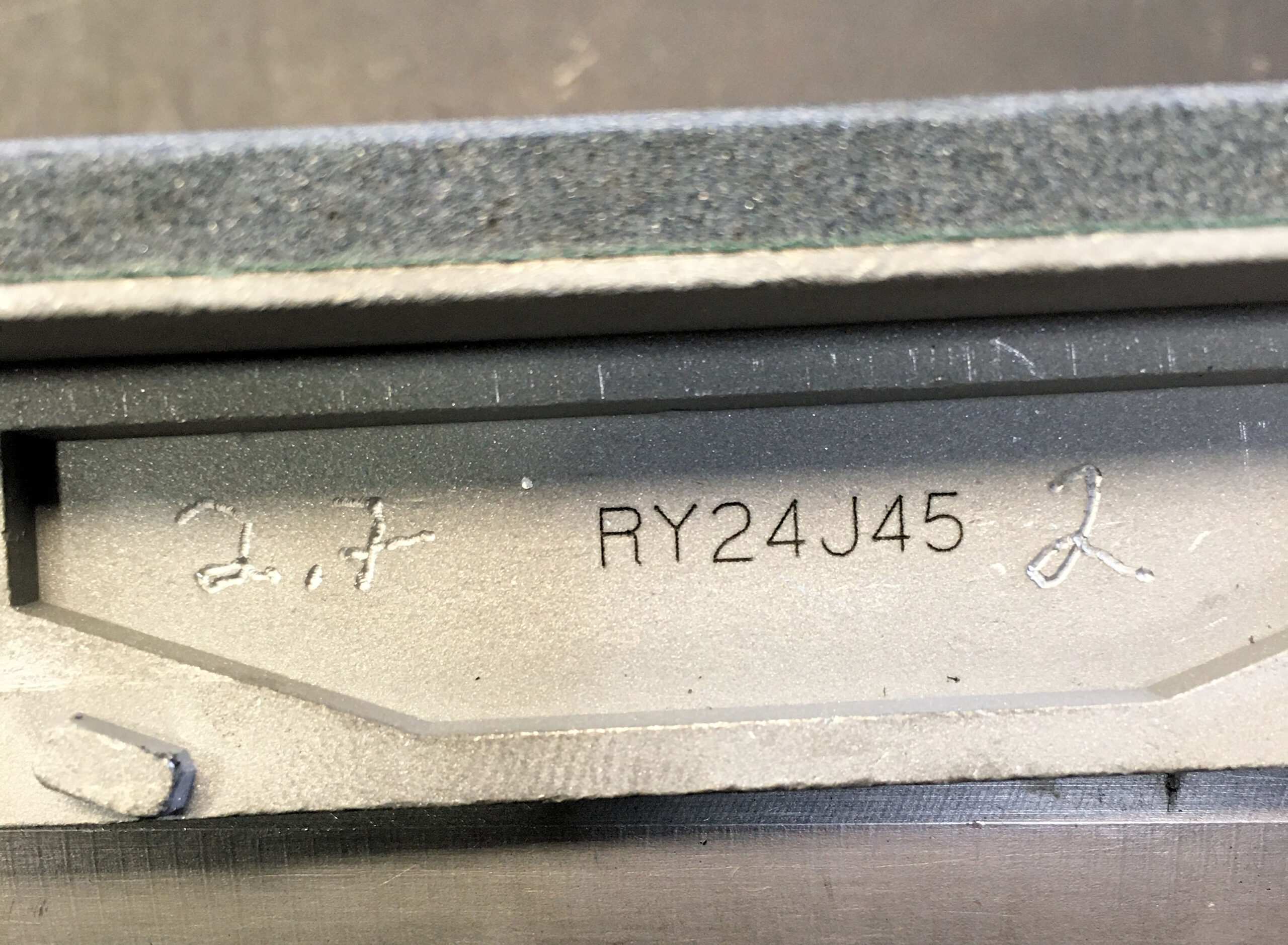

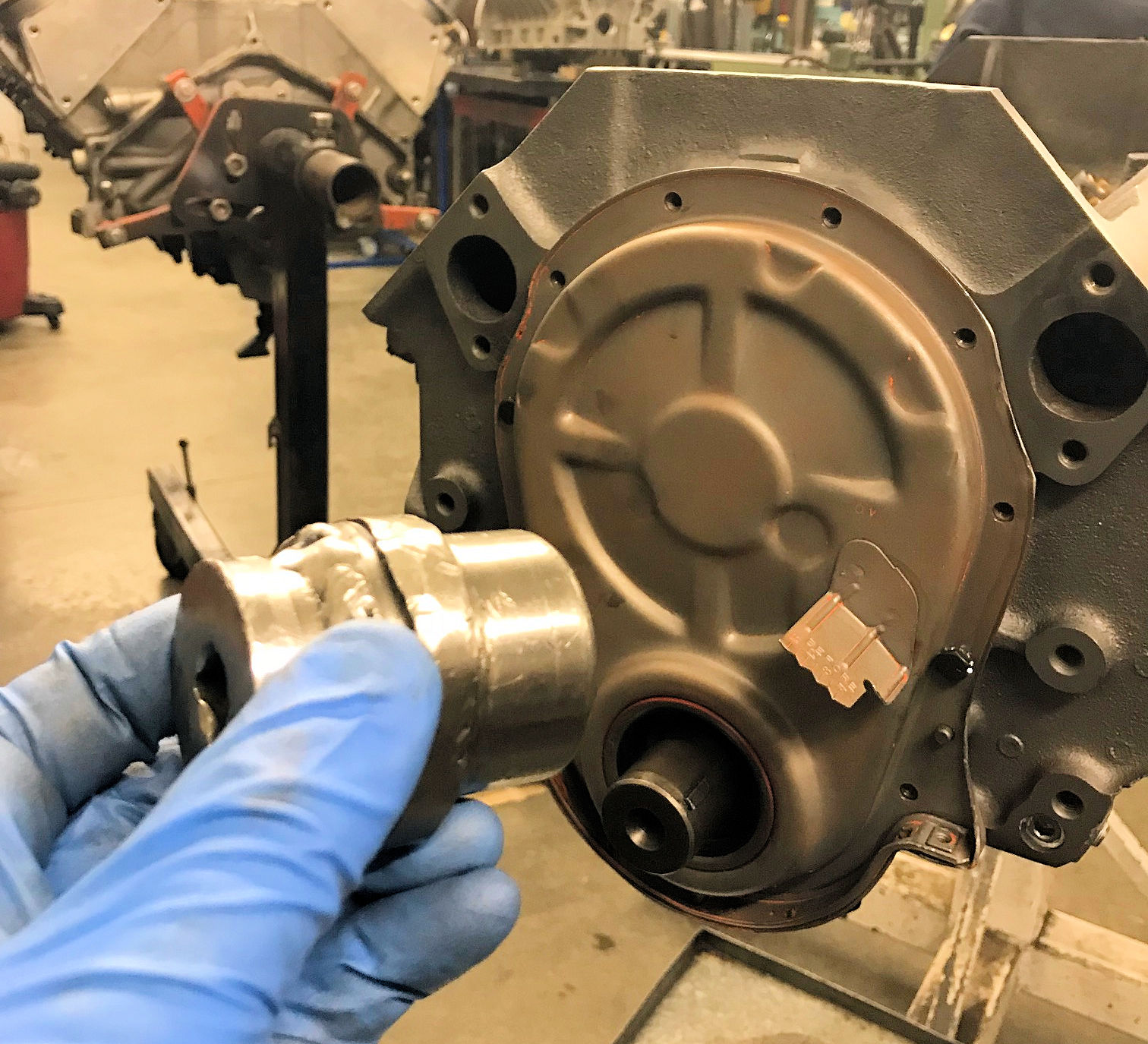

COVER ALIGNMENT On many engines with timing covers that are located by dowel pins, there can me misalignment problems that may result in a leak. To eliminate this is, I drill the dowel pin locator holes in the cover one or two sizes oversize. Then I set it up in place...

by Donnie Hurt | Dec 1, 2020 | OPERATIONS

THE SIX “P’s” Before machining remember, ” Proper Planning Prevents Piss Poor Performance ” and Murphy’s Law will have less of a chance to get you. There is nothing worse for the bottom line than finding a crack or that the cam bearings do not fit...

by Donnie Hurt | Dec 1, 2020 | BLOCK WORK

CHAMFERING BLOCKS I have a brand name #2100 ridge reamer that has a cylinder chamfering attachment. I use it on every block that I bore. It puts a perfect 60-degree chamfer on the top of each cylinder, every time. It does not take any longer to use it than the...

by Donnie Hurt | Nov 1, 2020 | OTHER SHOP WORK

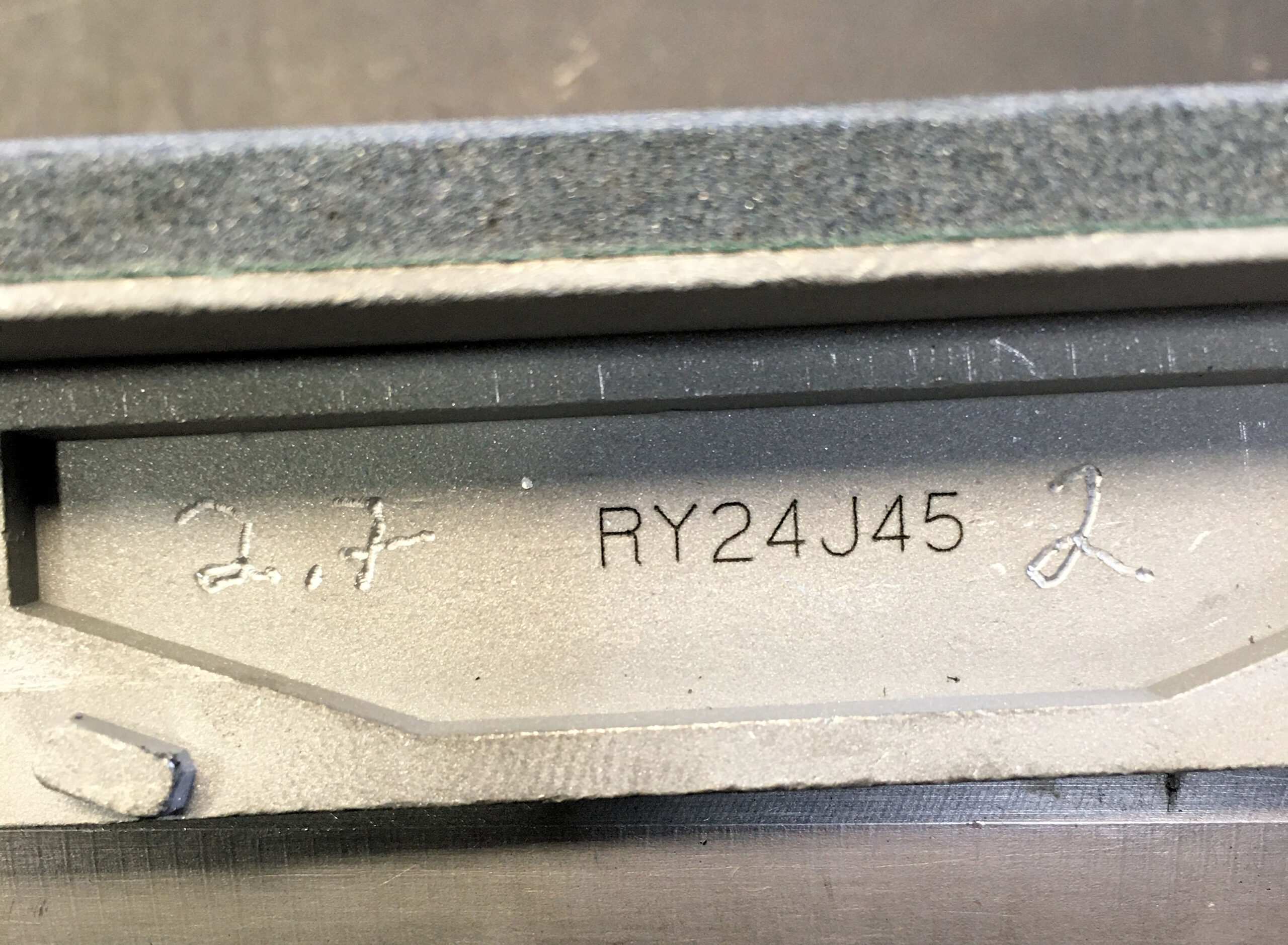

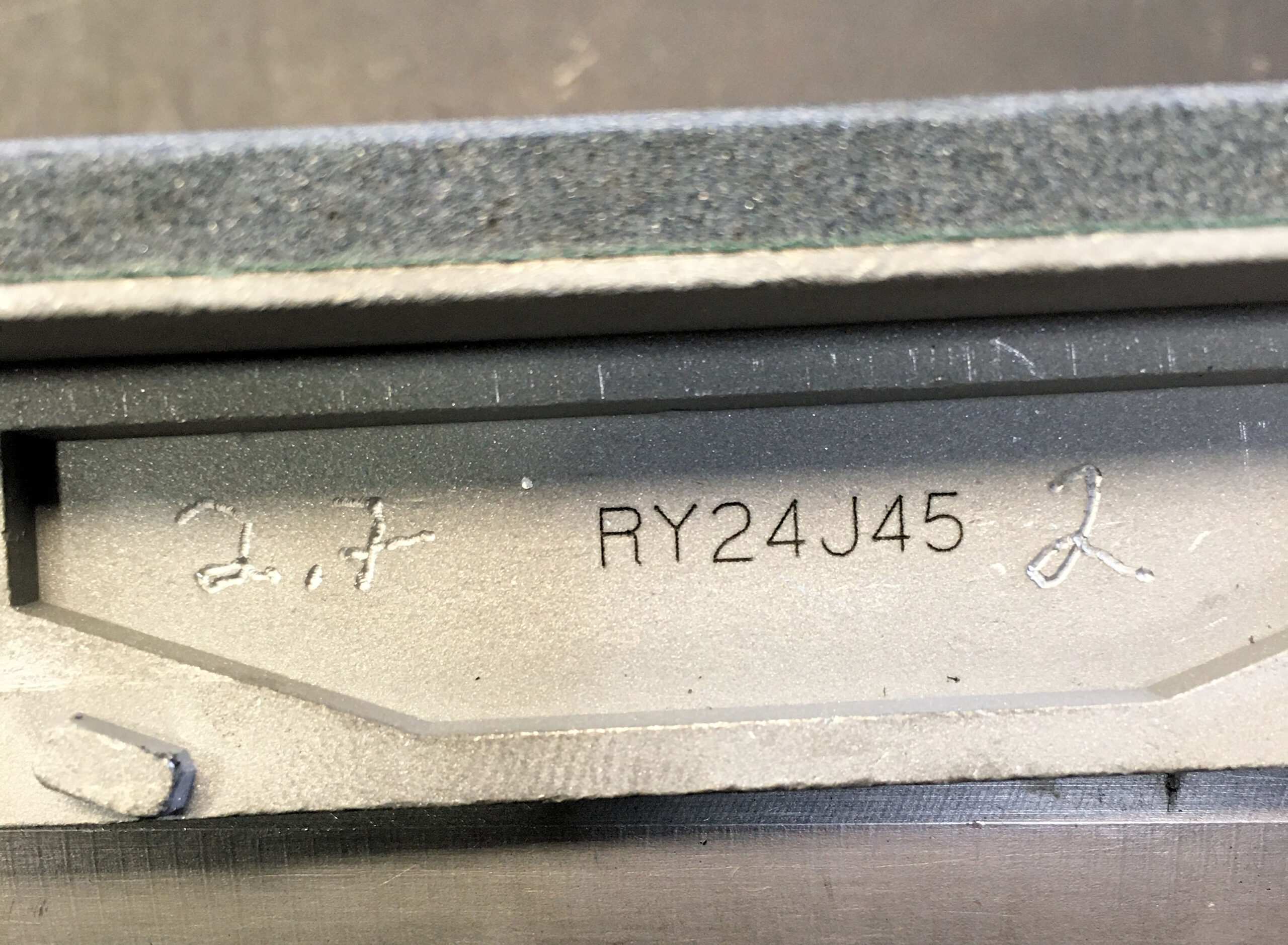

REPEATABILITY KEY TO PROFITABILITY When machining multiple parts, put your first part up against a stop like this small parallel. Machine your first one then set and zero the indicator. Now just chuck up the next part the same way. Now you do not have to measure each...