by Donnie Hurt | Sep 1, 2020 | BLOCK WORK

BORING TABLE When boring a single cylinder, I cut a hole in a table and mark holes to match the cylinder plate and drill out these holes. Now simply bolt the cylinder to the plate then mount it on the table. You won’t have to worry about stopping the boring bar before...

by Donnie Hurt | Sep 1, 2020 | PISTONS & RINGS

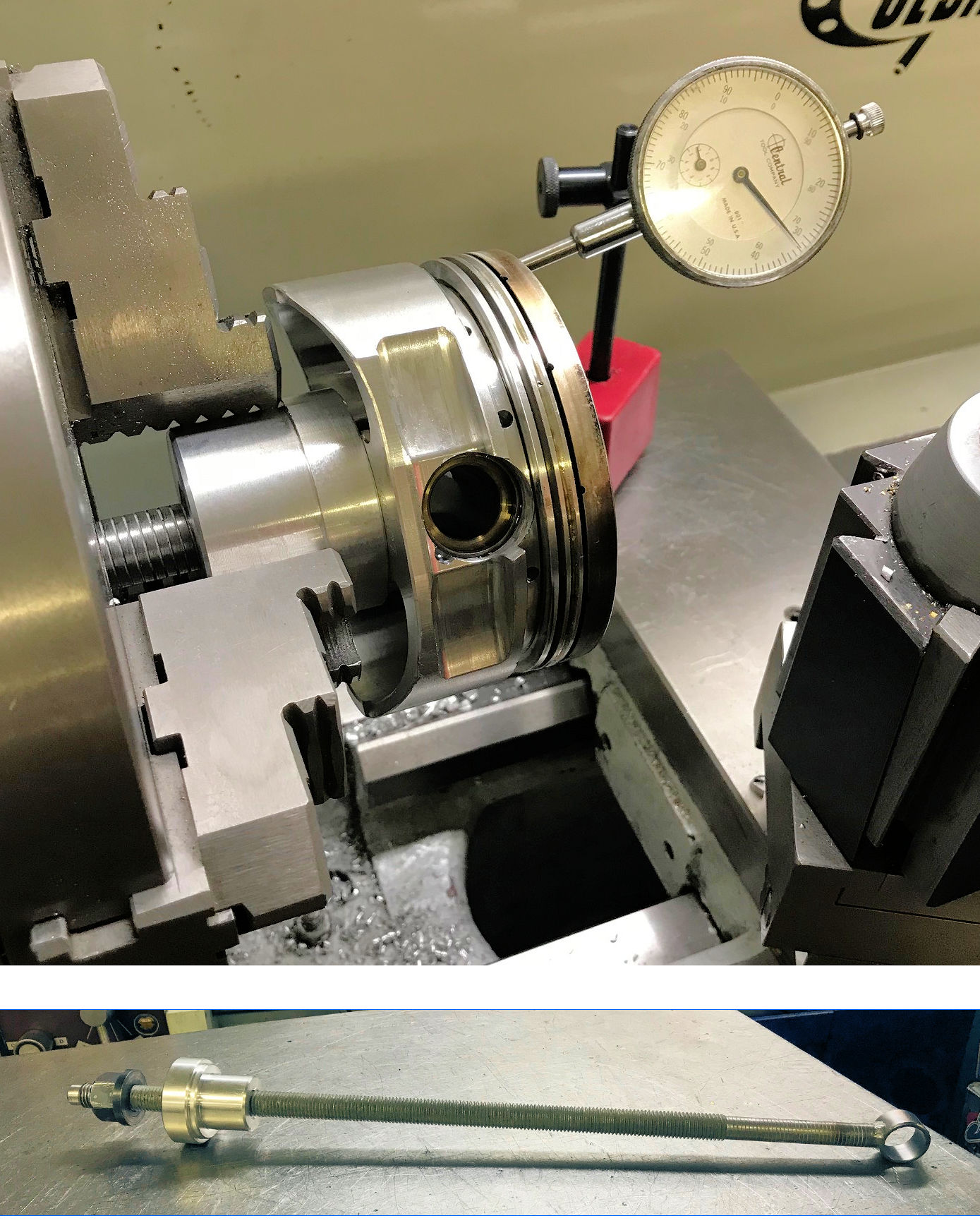

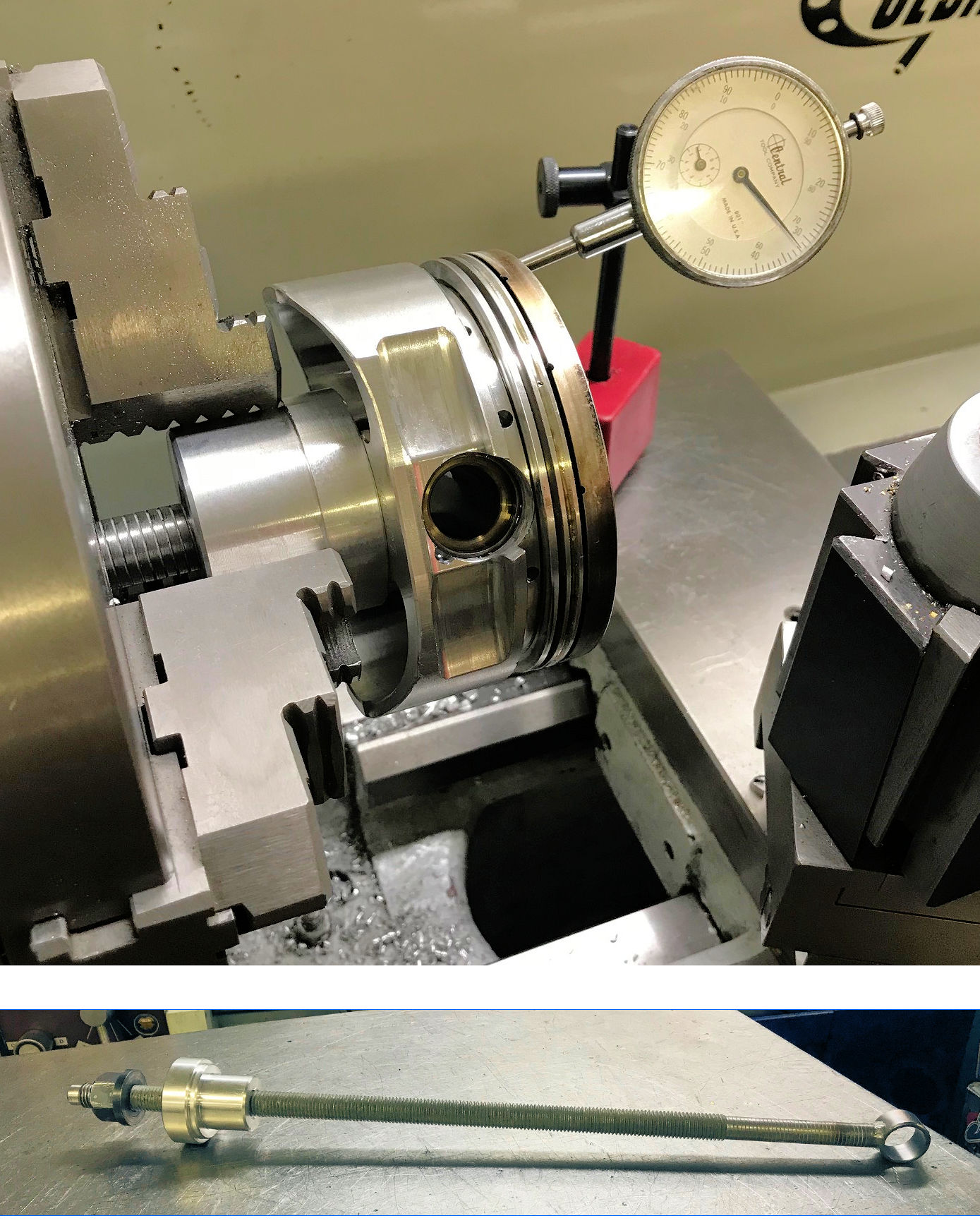

PISTON FIXTURE A simple way to chuck pistons into the lathe is to make a draw rod assembly that goes through the head stock of the lathe. I made a bushing to locate it and give the draw nut a place to seat. Sometimes you may have to make a ring adapter for the...

by Donnie Hurt | Sep 1, 2020 | CYLINDER HEADS

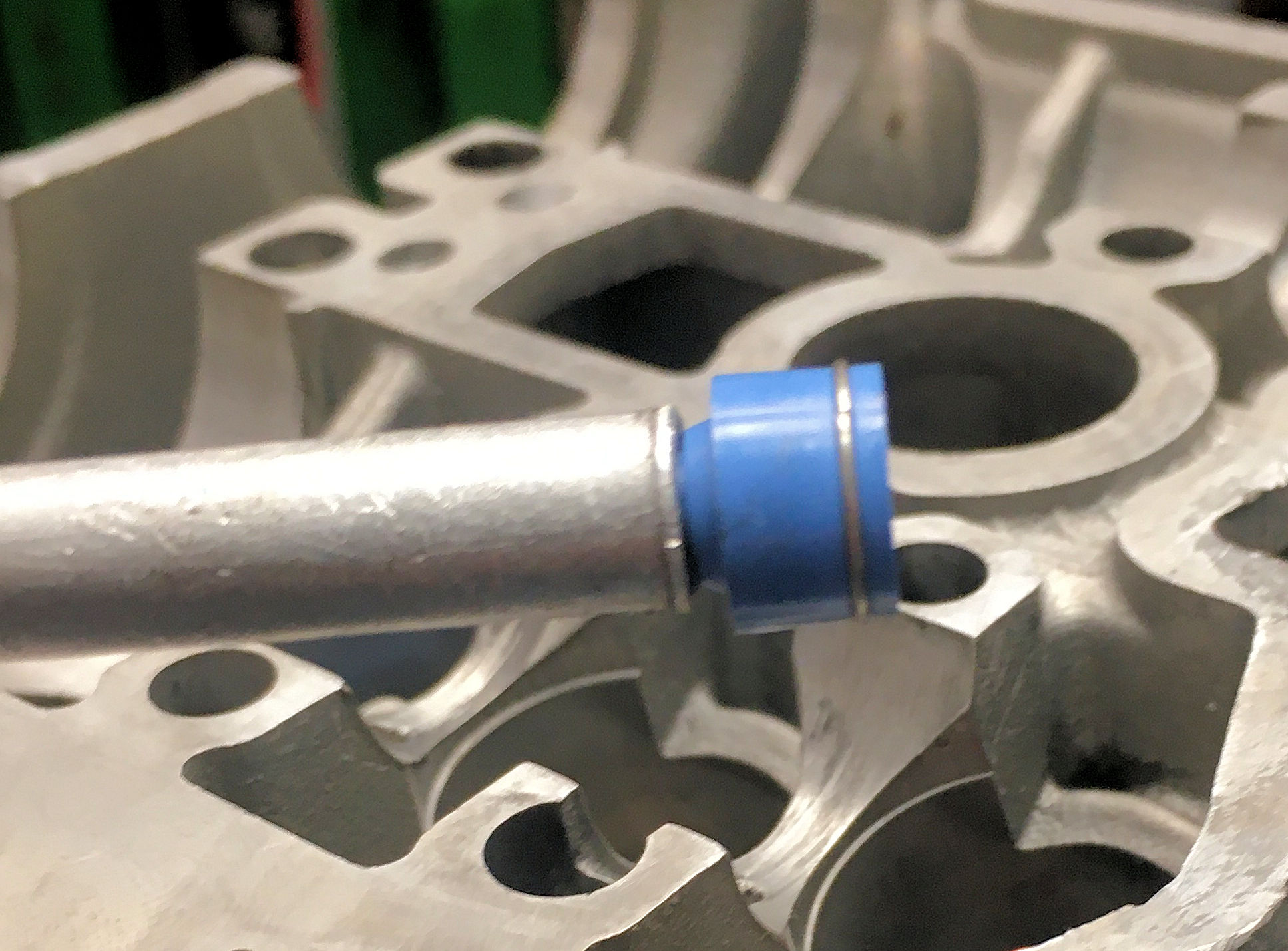

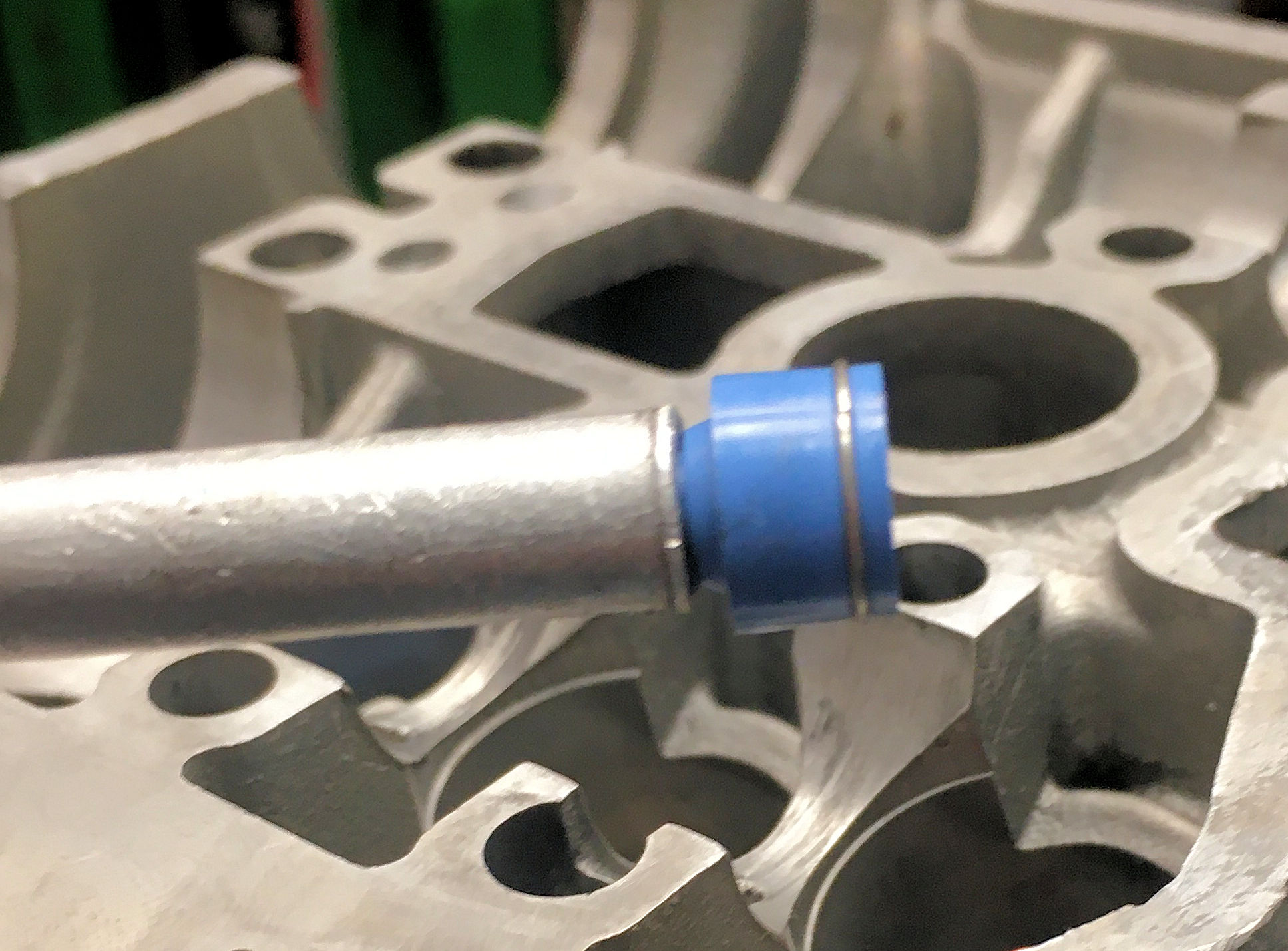

MAGNETIC SEAL When installing valve stem seals on OHC cylinder heads, I use a small pencil magnet on the top side of many valve seals to locate them over the valve stem. There is enough magnetic material on the seal from the tension band that the magnet holds the seal...

by Donnie Hurt | Sep 1, 2020 | BLOCK WORK

TEST FIT CAMS I have a good dozen cams to test fit the Cam Bearings after installing when I don’t have the customers Cam. I polished the journals and taped up the lobes to keep from marking up the bearings. This makes for a better looking, finished job. I also...

by Donnie Hurt | Aug 1, 2020 | DISASSEMBLY & CLEANING

BLASTING OBSERVATIONS Here’s a couple of tips regarding soda blasting. Soda is very fine and it can become very cloudy and difficult to observe your work. I have drilled fresh air intake holes around the periphery of the viewing window, which helps keep the area...