by Donnie Hurt | Jan 1, 2019 | TOOLING

INEXPENSIVE T-HANDLE BOLTS For 7/16” holes, take a 7/16” rocker arm stud, weld a metal pin at 90¨ on end and it becomes a T-Handle. Make 2 of them, this way you don’t need a wrench to take a lift chain off of an engine block. For ½” bolt holes you can do the same, but...

by Donnie Hurt | Jan 1, 2019 | CYLINDER HEADS

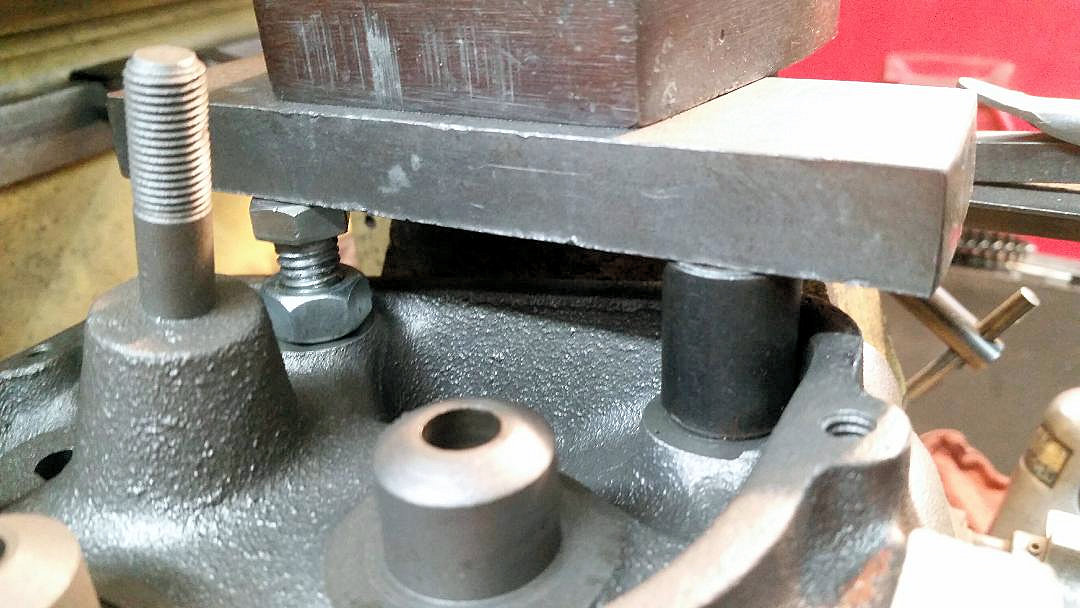

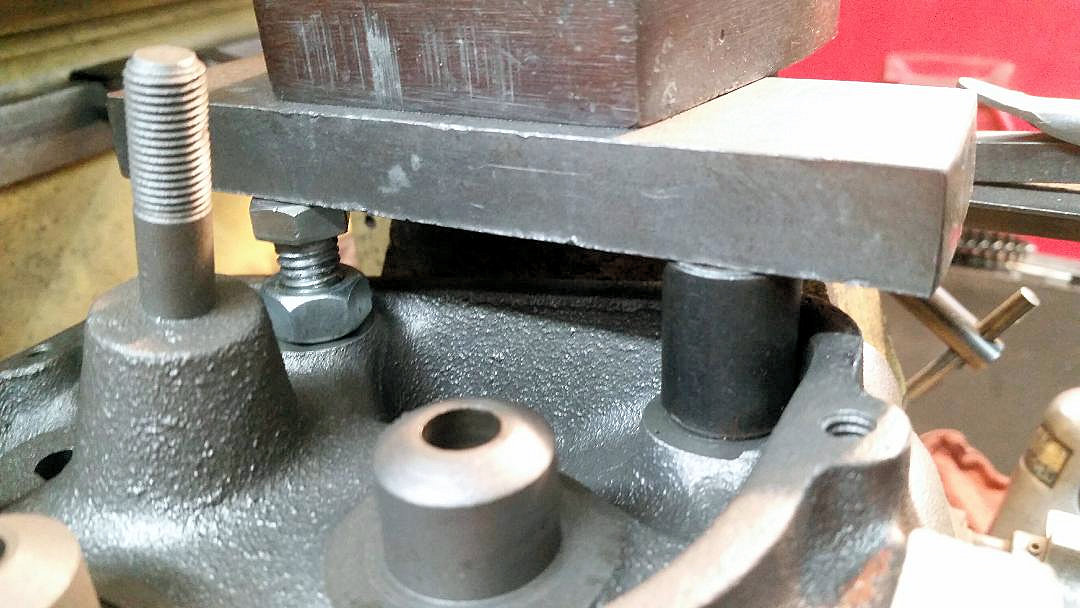

MOUNTED HEADS Mounting certain heads in a seat and guide machine can be difficult. This is especially true if the heads are uneven or the head bolt holes aren’t at the same height. I have a few pieces that came with the machine but they don’t solve all the...

by Donnie Hurt | Jan 1, 2019 | BLOCK WORK

NO MORE CAM BEARING ISSUES We’ve found that almost all issues related to camshafts being too tight in the bearings are caused by burrs in the cam tunnel which were caused by the original bearing installation at the factory. This is especially true with split cam...

by Donnie Hurt | Dec 26, 2018 | DISASSEMBLY & CLEANING

NOT JUST FOR SOCIAL MEDIA I have been taking photos of projects as customers drop them off. A picture from all sides will show any sensors, brackets etc. that the customer didn’t remove. A couple times a year a customer will tell me I forgot to give them back a sensor...

by Donnie Hurt | Dec 20, 2018 | DISASSEMBLY & CLEANING

MORE ON PIPE PLUGS I see a lot of pipe plugs today that don’t get removed or are all butchered up from guys struggling to get them out. I use a torch to heat up the tapered pipe plugs in the block until they glow red. Then I let it cool for a minute or so before I hit...