BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

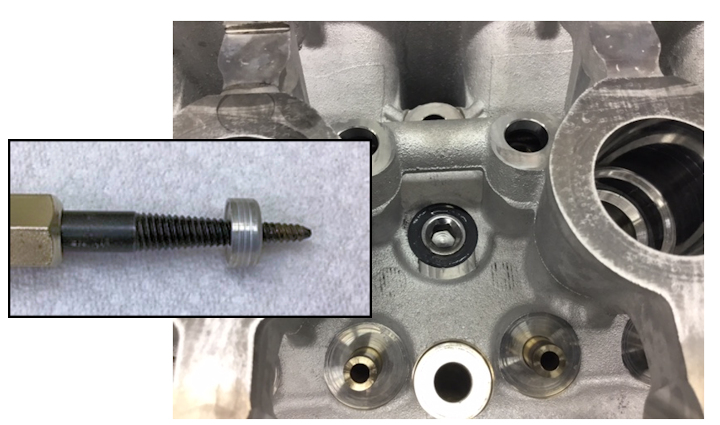

CHASER CHECKER

Apr 1, 2025 | BLOCK WORK

Sometimes when chasing the head bolt holes on Chevy blocks, you'll hit a casting knob. Then you think, will the bolt thread in far enough. I use a 7/16 valve guide and some washers to mimic the cylinder head thickness. This saves time by not having to measure every...

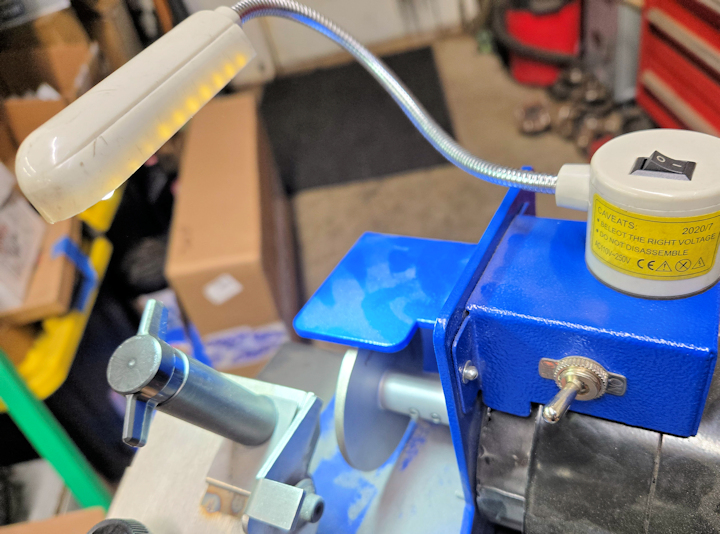

ADD A LITTLE LIGHT

Apr 1, 2025 | OPERATIONS

As we get older our vision gets worse, and I have found these inexpensive sewing machine lights help a lot. I have several around the shop in places like at tool setting fixtures, the ring grinder, the valve grinder and more. Arus Kinney AK's Engine And Machining ...

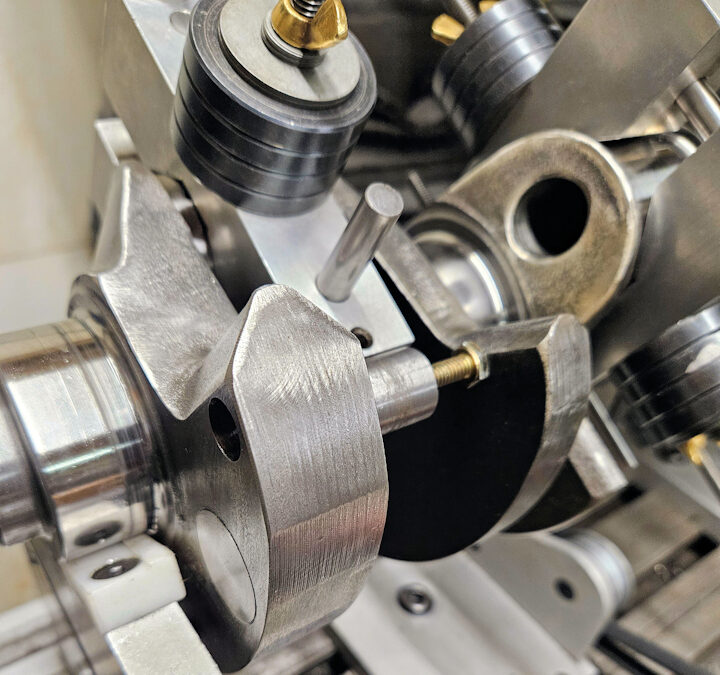

BALANCING MOCK-WEIGHT

Apr 1, 2025 | CRANKSHAFTS & CONNECTING RODS

Sometimes it's nice to be able to test what effect adding weight will have to a crankshaft balance. Since modern balancers also read cross planes, the placement can sometimes get tricky. This is especially true if the opposite side is close to the edge of the...

TEMPORARY CLAMPS

Mar 21, 2025 | OTHER SHOP WORK

These simple work holding clamps work excellently on the dyno to keep your sensor, oil and control wiring from getting burned or damaged. They're easier to use than tie wraps and save a bunch of time. You can buy the assortment pack really cheap at home improvement...

MINI REPAIR

Mar 21, 2025 | CYLINDER HEADS

If you work on Mini Cooper heads, it is important to replace the aluminum plugs, especially if the head has been overheated. These are notorious for popping out after the head has been reinstalled. It's an easy fix with a tapered 3/8 npt plug that is .462” deep. Tom...

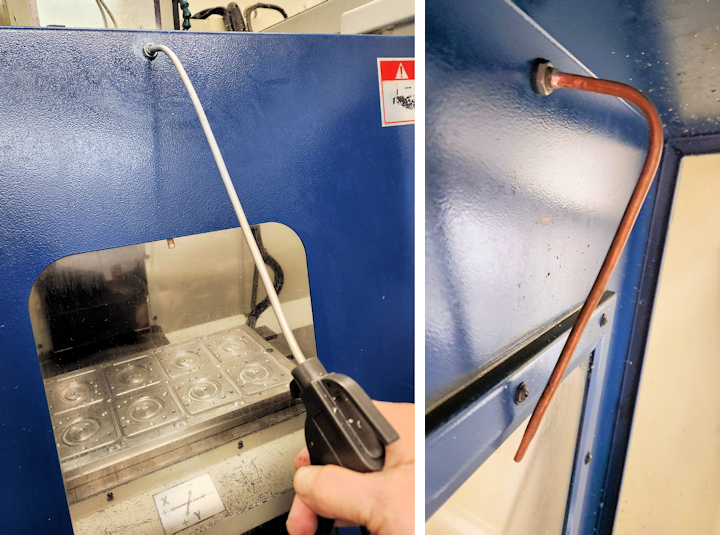

AIR BLAST FOR MACHINE WINDOWS

Mar 21, 2025 | TOOLING

Often, you cannot see through your CNC mill's cabinet window because coolant is splashing on the inside of the window. Rather than create a mess by opening the door to take a peek, install this simple window air blast tube. Your parts list will include a 12" piece of...