BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

E-Z BOLT REMOVAL

Feb 1, 2016 | OTHER SHOP WORK

E-Z BOLT REMOVAL Most bolts broken off flush or slightly below the surface can be easily removed using a MIG welder. Place a flat washer the same size as the broken bolt over the bolt and weld through the center. Then, place a 1⁄2” nut on top of the washer and...

LET’S GET VISUAL

Feb 1, 2016 | OPERATIONS

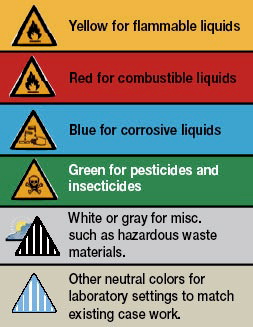

LET’S GET VISUAL ”Visuals” not only help eliminate waste, but can have additional positive impact on a shop’s operation, safety and cost. *Safety glasses (with side shields) should be mandatory in all shop areas; not just machining, grinding, welding, etc.. This can...

TWO HAND TIPPING

Feb 1, 2016 | CYLINDER HEADS

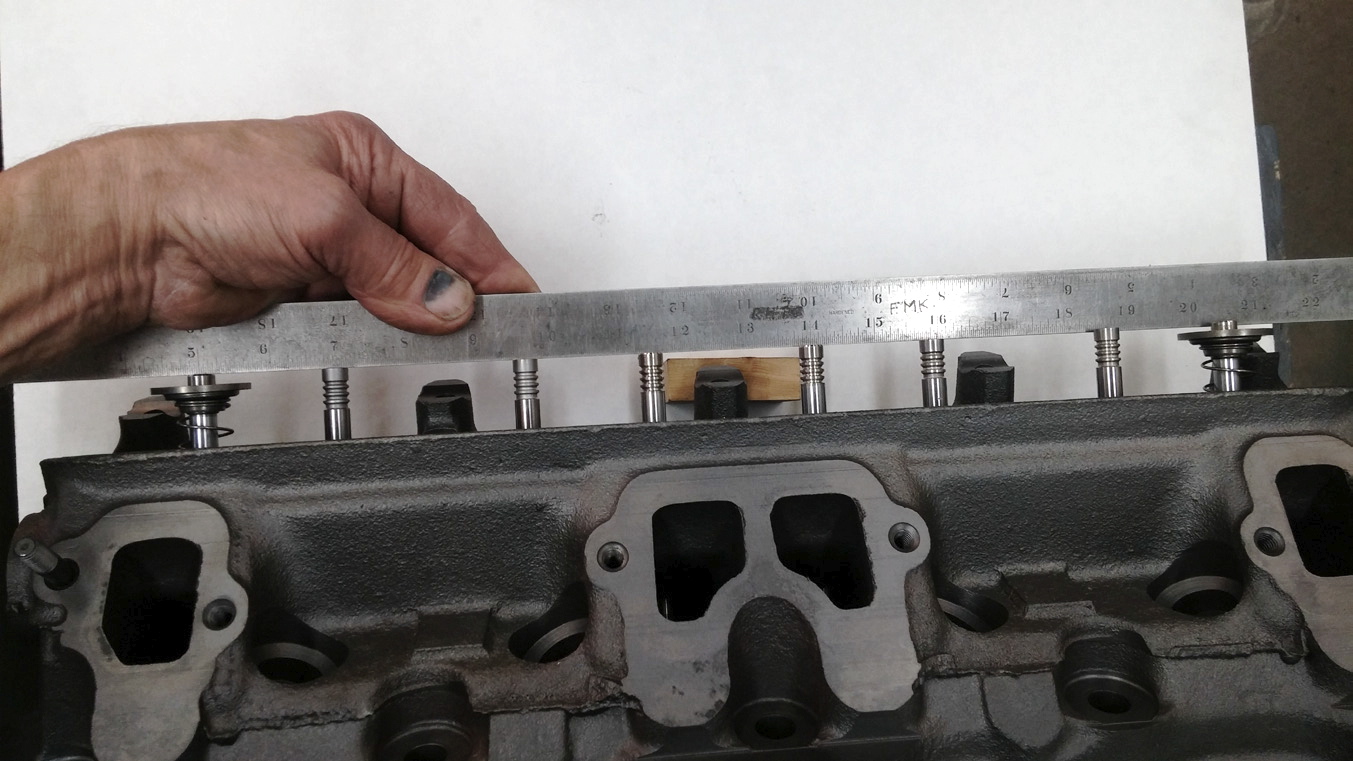

TWO HAND TIPPING I’ve found an easy way to set the valve stem height on heads. I get the two end valves to spec, then install light springs and retainers. This way I can hold the ruler across the top of the tips to adjust the others without needing 3 hands. Randy...

OLDS BLOCK REPAIR

Jan 1, 2016 | BLOCK WORK

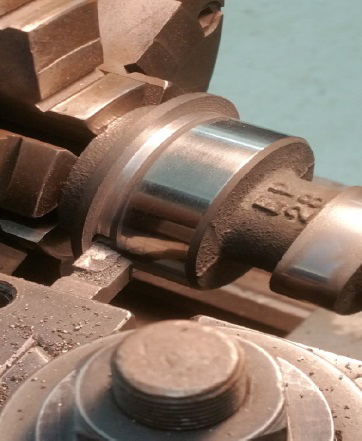

OLDS BLOCK REPAIR Sometimes the front of Oldsmobile blocks get worn and chewed up by the camshaft flange. This is often caused by additional load from a high pressure or high volume oil pump which makes the distributor work harder and pulls the cam back towards the...

HEAD SHOP AS A MILL

Jan 1, 2016 | OTHER SHOP WORK

HEAD SHOP AS A MILL When we need to plunge mill or drill an irregular object, such as when removing a broken bolt or stud in a motorcycle part, we use our seat and guide machine to hold and locate the part. The air clamp, air float and roll over fixture make short...

REAR MAIN SEAL SEAL

Jan 1, 2016 | GASKETS & SEALING

REAR MAIN SEAL SEAL I use RTV on the back side of most rear main seals. This is a great safety measure on rubber seals and a must on early rope rear main seal style blocks when using a neoprene type conversion seal. Splitting the alignment of the seal to block is...