BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

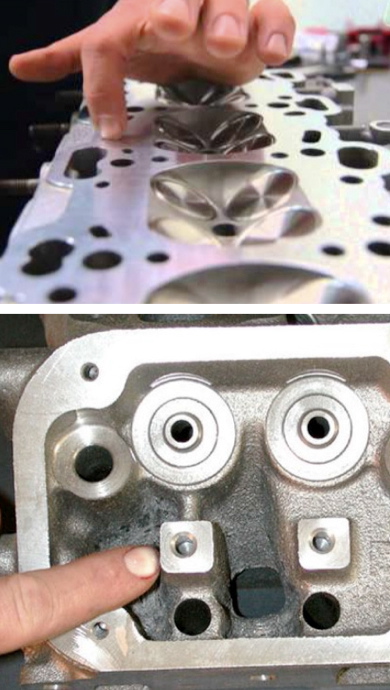

HD GUIDE REPLACEMENT

Jan 1, 2016 | CYLINDER HEADS

HD GUIDE REPLACEMENT On older Harley Davidson Pan, Shovel, Ironhead and many other cylinder heads, flanged guide removal can lead to damage to the host bore in the head. Many times the guide is distorted and will tear up the bore as it passes back through. To stop...

MINI GROOVES AND ACCUMULATOR GROOVES EXPLAINED

Jan 1, 2016 | PISTONS & RINGS

MINI GROOVES AND ACCUMULATOR GROOVES EXPLAINED Piston ring second land accumulator grooves provide an area for escaping combustion gases and crankcase pressures, that get past the piston rings, to gather and dissipate. Without this feature, the passing compression...

EASY PARTING LINE DEBURRING

Dec 1, 2015 | CRANKSHAFTS & CONNECTING RODS

EASY PARTING LINE DEBURRING When I torque & check connecting rods for size, the surface with the bolt is hard to deburr first. I had some files drilled with carbide bits to .010” over 3/8”, 7/16” & 1/2”. Now it’s an easy task to deburr and looks great. Randy Torvinen...

THE MYTH OF THE NEW BARE CASTING

Dec 1, 2015 | CYLINDER HEADS

THE MYTH OF THE NEW BARE CASTING There may be some misconception in the automotive machine world with regards to new cylinder head castings. Over the years new car manufacturers have been very kind to our industry. It seems that every couple of years a new problem...

RESIZE CRACKED RODS? YES YOU CAN

Dec 1, 2015 | CRANKSHAFTS & CONNECTING RODS

RESIZE CRACKED RODS? YES YOU CAN There is a way to recondition the so-called “cracked” rods, or powdered metal connecting rods. I use a media made of coal slag that can be found at most home improvement stores. You have to blast the 4 mating surfaces on the rod and...

CBN SHARPENING

Dec 1, 2015 | TOOLING

CBN SHARPENING We sharpen our CBN bits in our mill using our diamond coated carbide valve seat tip sharpener. We hold the CBNs in a 1/2” collet and turn the mills head parallel to the table, then set the carbide sharpener on the mill table. You aren’t applying any...