BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

MIC CHECK, CHECK

May 1, 2024 | TOOLING

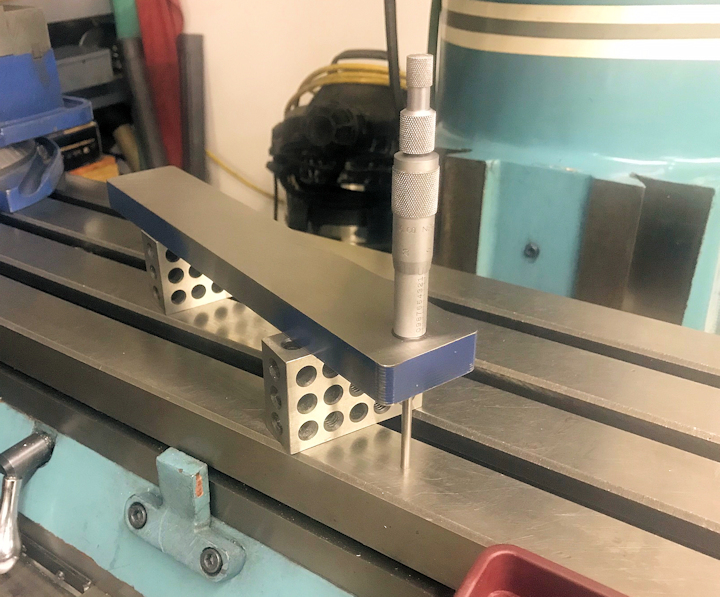

MIC CHECK, CHECK One often overlooked item for regular calibration is the common block deck mic and depth mics. Simply lay it on the corresponding precision blocks on your mill table, or known true surface, and check them once in a while. Ron Flood Cedar Machine North...

THE FREE NICKEL TOUR

May 1, 2024 | OPERATIONS

THE FREE NICKEL TOUR Often a new customer will stop by saying, "So-and-So at XYZ Garage told me to stop by and ask for the 'Free Nickel Tour'. I'm interested in having a high-performance engine built." I have found this too be far more productive marketing than...

PAIR OF GLASS PLIERS

May 1, 2024 | TOOLING

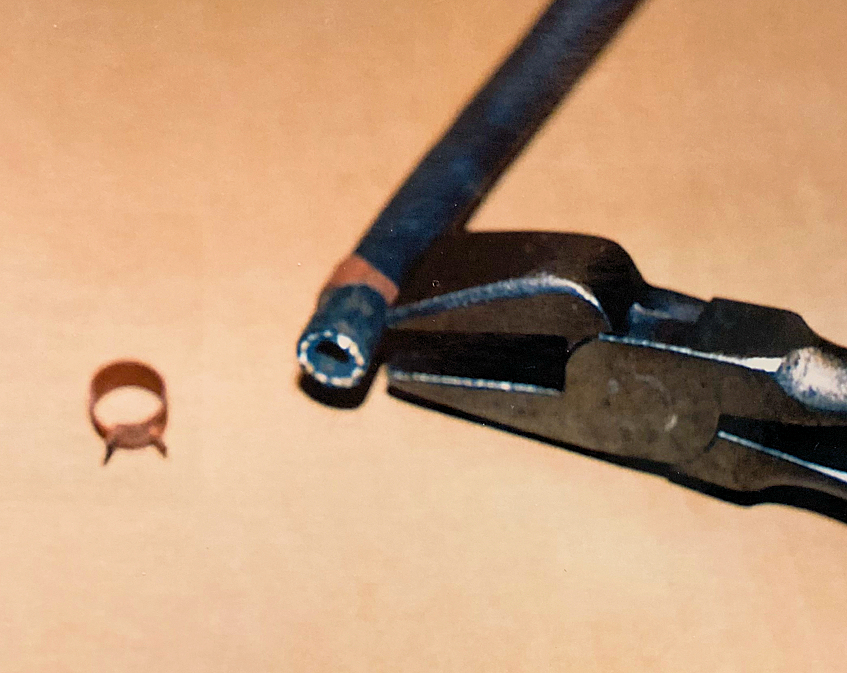

PAIR OF GLASS PLIERS If you have trouble with flat-band spring-type hose clamps, try using a pair of glass pliers. The jaws are so wide that they hold any hose clamp very securely. They make it easy to compress the clamp for removal, installation, or repositioning....

T-TAPS

Apr 1, 2024 | DISASSEMBLY & CLEANING

T-TAPS I have some pipe taps with a T-handle welded on we keep in the cleaning department. It's easy to clean the rust or sealer from oil galleys and block drains. You cannot make the holes deeper with these, and they don't walk away with the T-handle on them. Randy...

COAT-IT HANGER

Apr 1, 2024 | GASKETS & SEALING

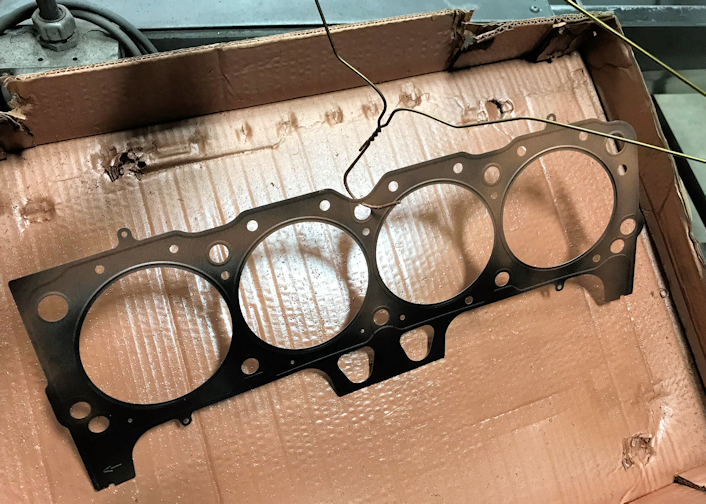

COAT-IT HANGER If you coat head gaskets with copper coat spray, using a clothes hanger as a support is a convenient way to keep the spray off of your hands and to keep your gasket from sticking to another surface. Adam Cofer Don Ott Racing Engines York Springs, PA...

LOAD BLOCKS WITH EASE

Apr 1, 2024 | DISASSEMBLY & CLEANING

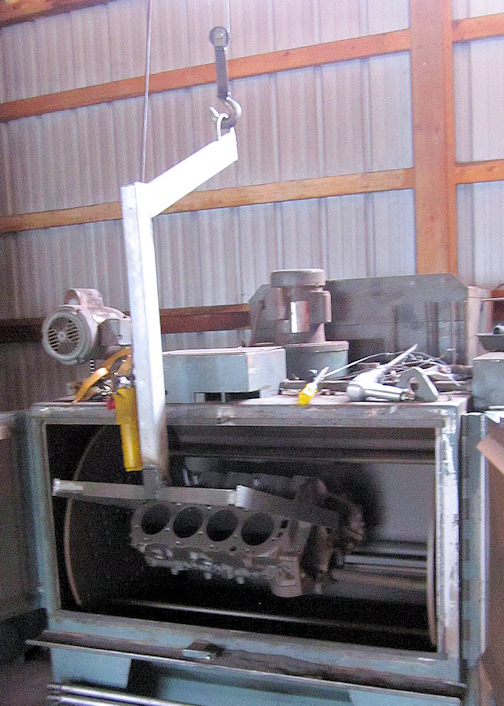

LOAD BLOCKS WITH EASE I have an older thermal cleaning system by Peterson. The shot blaster is designed more for cylinder heads than blocks as it is a side loading machine. To wrestle blocks into the machine was not reasonable so I came up with this simple solution to...