BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

INSTALLATION TOOL TOOL

Jun 1, 2022 | CRANKSHAFTS & CONNECTING RODS

INSTALLATION TOOL TOOL When installing a reluctor wheel on an LS crankshaft, using the brand name alignment tool, use a piece of 4.5" pipe, notched and with a bar welded on the back to take the hammer blows. I can avoid banging on the tool and this provides a better...

FILL IT TO THE TOP

Jun 1, 2022 | PISTONS & RINGS

FILL IT TO THE TOP If you have a piston with a dome volume, you're unsure of, here's an easy way to check. Wrap a single layer of thick packing tape around the head land, taller than the dome. It will maintain the full round shape if you're careful. Fill it to the tip...

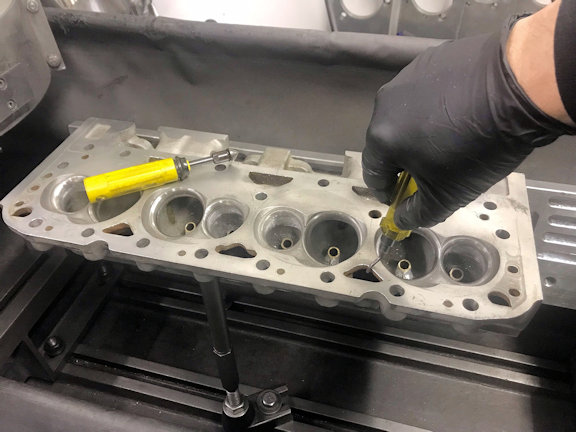

RECYCLED MEASURING TOOL

Jun 1, 2022 | CYLINDER HEADS

RECYCLED MEASURING TOOL To install valve guides on my heads, I just make custom fit measuring tools out of the 6" steel rules I get at the trade shows. I cut them to fit in the lifter bores of the overhead cam engines. It's quick and simple. Matt Peebles Matts Machine...

QUICK EASY STRAP WRENCH

May 1, 2022 | TOOLING

QUICK EASY STRAP WRENCH The diameter of a diesel engine oil filter was larger than my biggest filter wrench, so I made this strap wrench from an old spark plug socket, worn-out poly-V serpentine belt, and a short length of PVC 1/2" schedule 40 pipe. I used an angle...

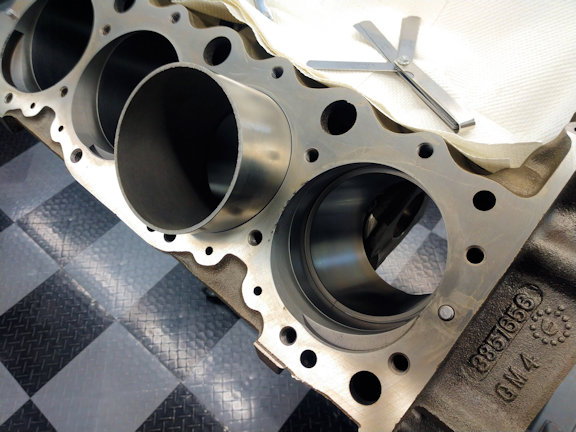

IT’S HIP TO BE SQUARE

May 1, 2022 | PISTONS & RINGS

IT’S HIP TO BE SQUARE It's tough to end gap rings in a canted deck engine such as a 409 Chevy. Turn a scrap piece of cylinder sleeve to about .003’ smaller than the bore. Make sure it’s long enough. Use that and it will allow you to push the rings down the bore...

CLEAN CUT

May 1, 2022 | OTHER SHOP WORK

CLEAN CUT When surfacing blocks or heads, it’s a good idea to deburr all the water jacket and bolt holes before making cuts. Many heads have scale and residue on those areas that can cause “drag” marks when the tool bit passes over. Marine heads, or any head that’s...