BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

EXTRACTING SHARP EDGES

Jan 1, 2022 | DISASSEMBLY & CLEANING

EXTRACTING SHARP EDGES I like to chamfer the sharp edges on lifter bores after shotblasting blocks. I use a spiral flute extractor and just rotate it clockwise a few times with my fingers to remove any peened over edges. I find that it works better than a lot of my...

BLOW THROUGH VACUUM

Jan 1, 2022 | TOOLING

BLOW THROUGH VACUUM If you end up chasing threads or tapping on a machine and don’t want to make a mess blowing them out, here’s a quick tip. Drill a hole in your vacuum cleaner nozzle and feed your blow gun nozzle through it. Now suck the chips up as you blow the...

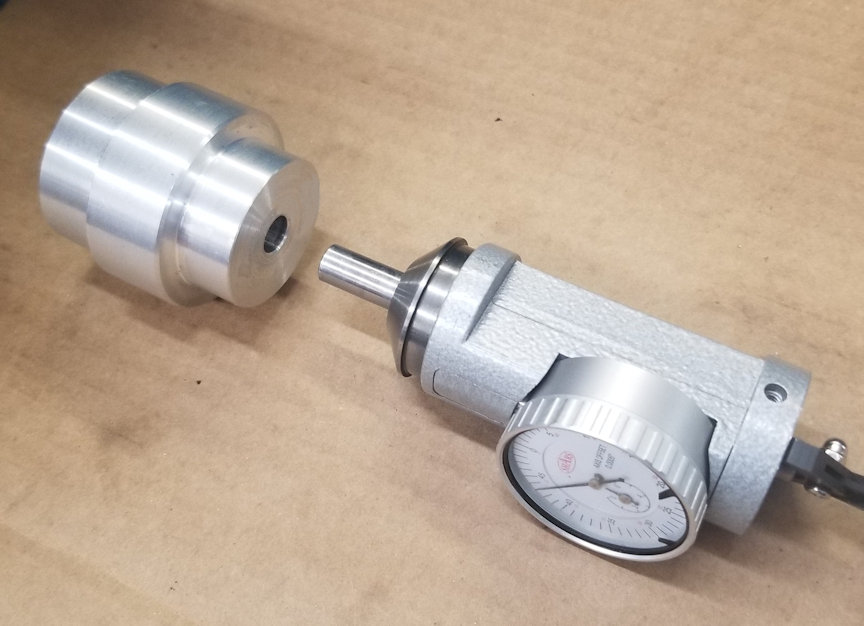

INDICATOR ADAPTER

Dec 1, 2021 | TOOLING

INDICATOR ADAPTER Most Co-Ax indicators have a 3/8" or 1/2" diameter stem. Instead of wasting time closing the lathe chuck to hold the indicator and then more time opening it back up to hold a larger diameter work piece, make a simple stepped adapter with a precision...

SEAT SPUD

Dec 1, 2021 | TOOLING

SEAT SPUD For machining custom valve seats, in addition to the expansion arbor, I have a simple aluminum spud and lock. I can quick machine it down for whatever seat I need. It started out as a 1-foot-long piece of round stock, and I just keep drilling and tapping as...

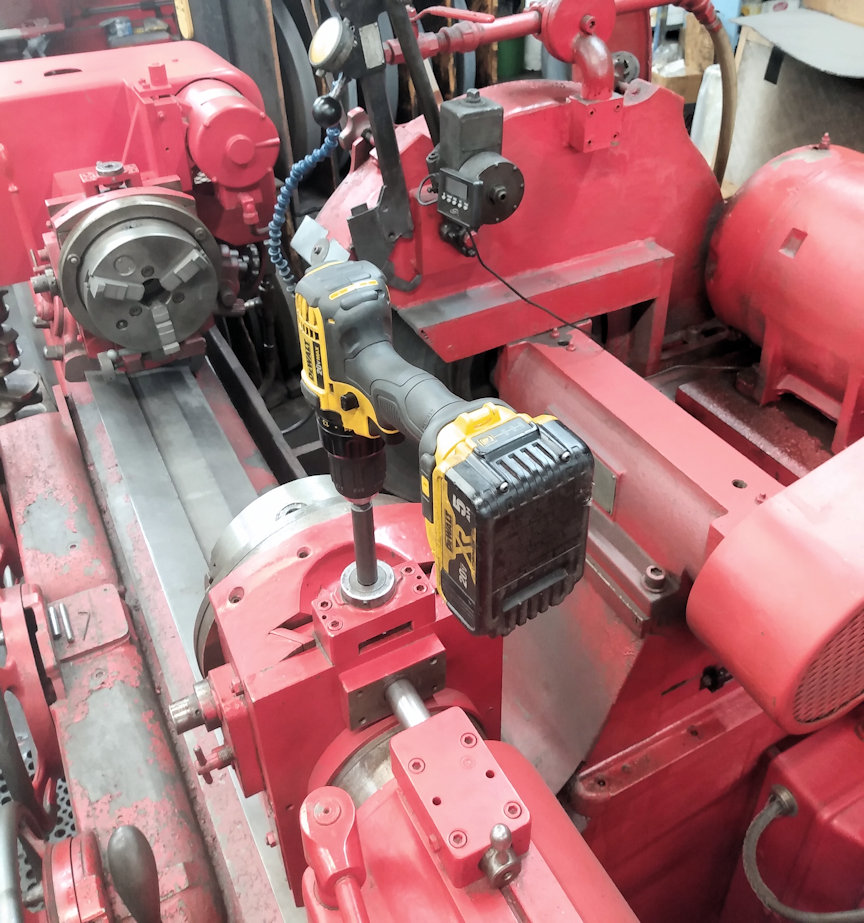

POWER ADJUSTMENTS

Dec 1, 2021 | TOOLING

POWER ADJUSTMENTS To save time, we use a half inch cordless drill to power our stroke and counterweight adjustments on our crankshaft grinder machines. Adney Brown Performance Crankshaft Ferndale, MI DECEMBER, 2021

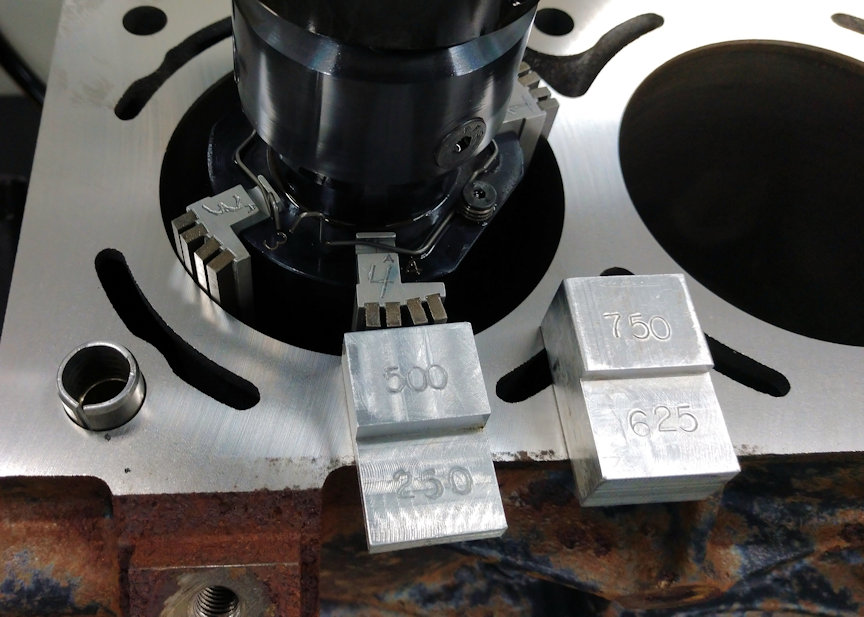

SET UP BLOCKS

Dec 1, 2021 | TOOLING

SET UP BLOCKS Keep your tape measure in the toolbox when doing set ups that you repeat time and time again. Make some gauge blocks or fixtures, whatever it takes to save time setting up your machines. Randy Torvinen Torvinen's Machine Menahga, MN DECEMBER, 2021