by Donnie Hurt | Jan 26, 2026 | CRANKSHAFTS & CONNECTING RODS

When drilling on cranks for balancing, install a simple jackscrew between the counterweights to eliminate flex at the rod journal. I use the same ones for drilling in line with the crank for heavy metal install, if the counterweight is unsupported on the drill...

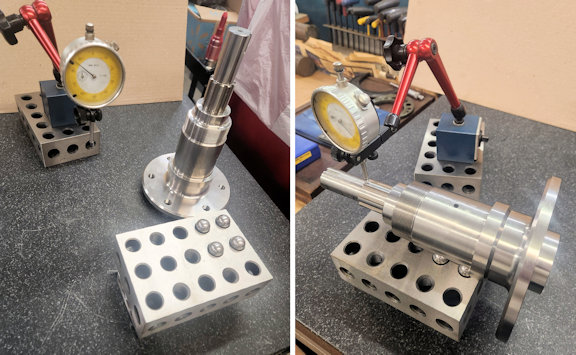

by Donnie Hurt | Jan 12, 2026 | OTHER SHOP WORK

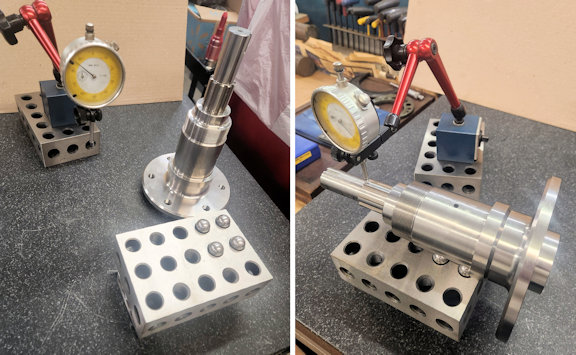

Here’s an easy fixture for inspecting run-out on shafts with a diameter too large to fit in your V-blocks. We place 2-4-6 blocks (or you can use a couple of 1-2-3 blocks) on our granite surface plate. You could also use a mill table. Next drop 4 steel ball bearings...

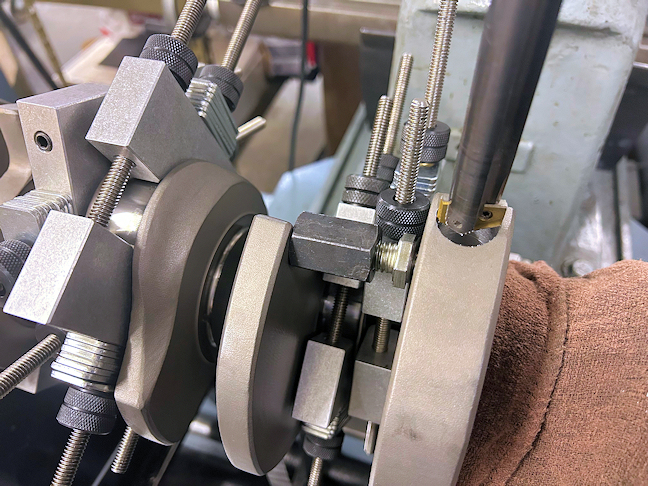

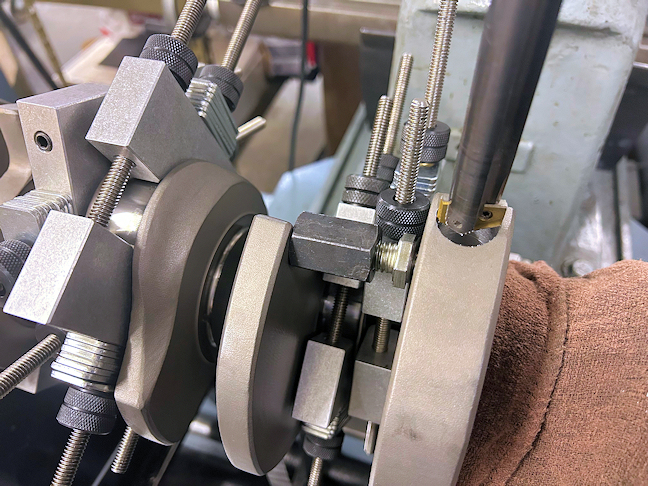

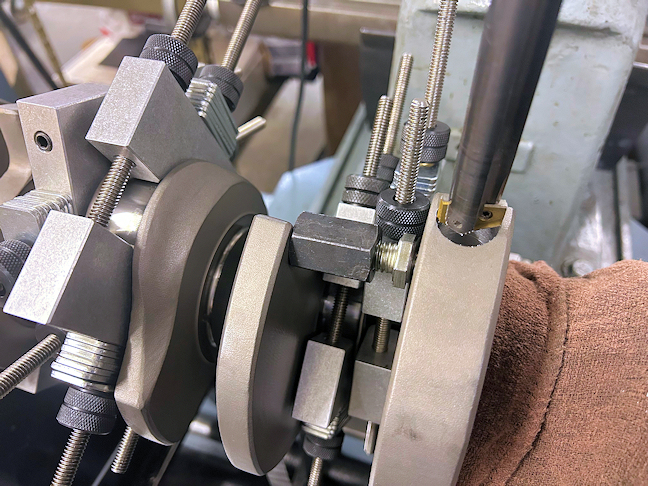

by Donnie Hurt | Sep 8, 2025 | CRANKSHAFTS & CONNECTING RODS

I hone the I.D. of an old harmonic balancer to slide on the crank, so it works as a stabilizer when removing and installing tone wheels. Arus Kinney AK’s Engine and Machining Covington, GA

by Donnie Hurt | Aug 1, 2025 | CRANKSHAFTS & CONNECTING RODS

When you’re balancing a crank and you go to make a smaller hole larger, the drill always wants to walk around the perimeter of the hole. I find that if I pre-drill to the correct size with a step drill, it eliminates this issue. Adney Brown Performance...

by Donnie Hurt | Jul 7, 2025 | CRANKSHAFTS & CONNECTING RODS

When I’m balancing a crank and need to add Mallory-metal, I chuck a marker or paint pen into the drill and peck a mark on the counterweight. Once I remove the crank to go to the mill to drill through the side, I have a nice reference for where to center the hole. Big...