by Donnie Hurt | Jul 7, 2025 | CRANKSHAFTS & CONNECTING RODS

When I’m balancing a crank and need to add Mallory-metal, I chuck a marker or paint pen into the drill and peck a mark on the counterweight. Once I remove the crank to go to the mill to drill through the side, I have a nice reference for where to center the hole. Big...

by Donnie Hurt | Apr 1, 2025 | CRANKSHAFTS & CONNECTING RODS

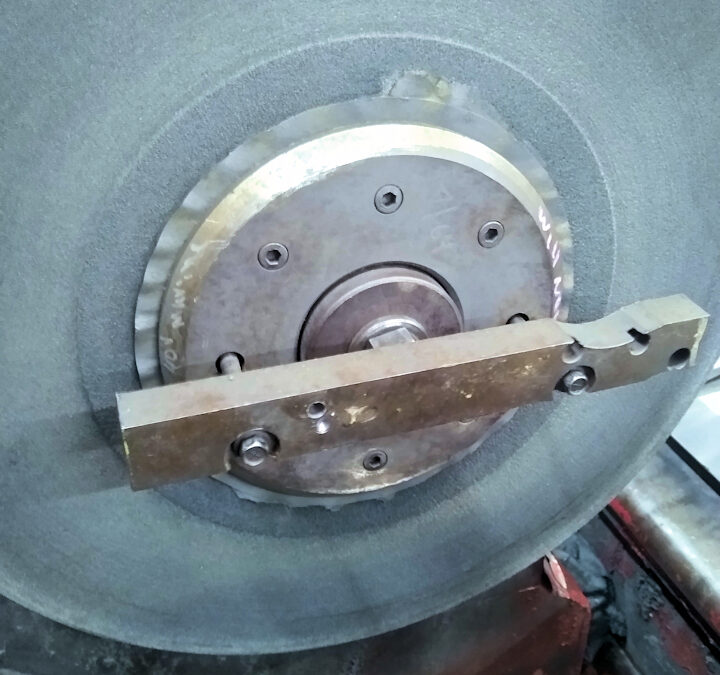

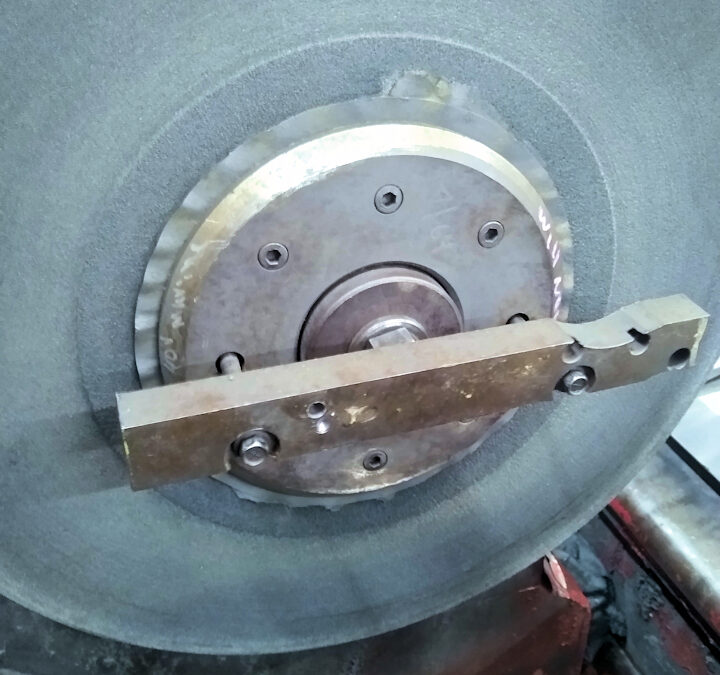

Sometimes it’s nice to be able to test what effect adding weight will have to a crankshaft balance. Since modern balancers also read cross planes, the placement can sometimes get tricky. This is especially true if the opposite side is close to the edge of the...

by Donnie Hurt | Dec 23, 2024 | CAMSHAFTS & VALVE TRAIN

Typically, most places that grind crankshafts store them on end before and after grinding, but that gets to be difficult when they have pins in the flange. We found that an anti-fatigue mat with holes in it works perfectly to keep them upright. Adney Brown Performance...

by Donnie Hurt | Dec 23, 2024 | CRANKSHAFTS & CONNECTING RODS

If you’re taking an engine apart and are unsure of the cubic inch or the crank stroke, here is a quick way to figure it out. Simply rotate the engine until one piston is at BDC. Take a measurement from the deck of your block down to the deck of the piston. You can use...

by Donnie Hurt | Dec 18, 2024 | CRANKSHAFTS & CONNECTING RODS

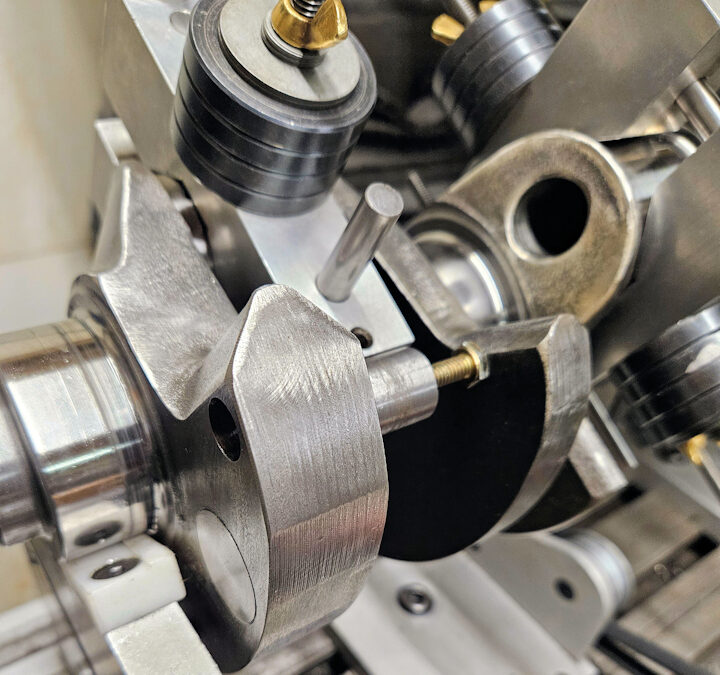

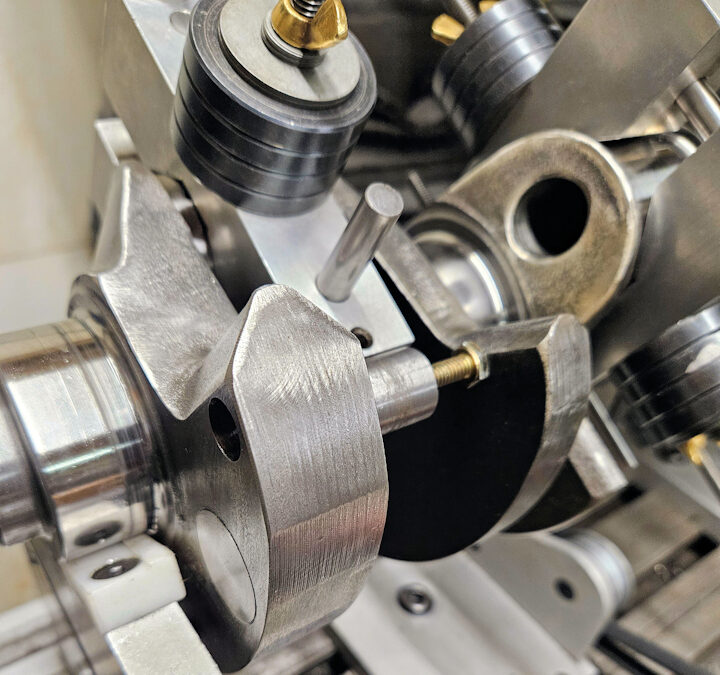

Every once in a while, you’ll have a hub that wants to stick firmly on a crankshaft grinder spindle. Instead of beating on it with a hammer, when you have precision bearings involved, we keep a piece of scrap steel with two holes that correspond with two of the...