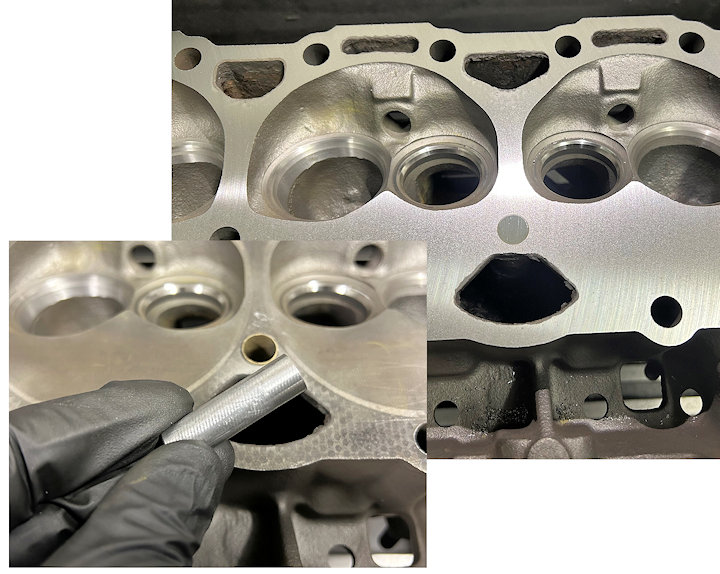

by Donnie Hurt | Dec 9, 2025 | CYLINDER HEADS

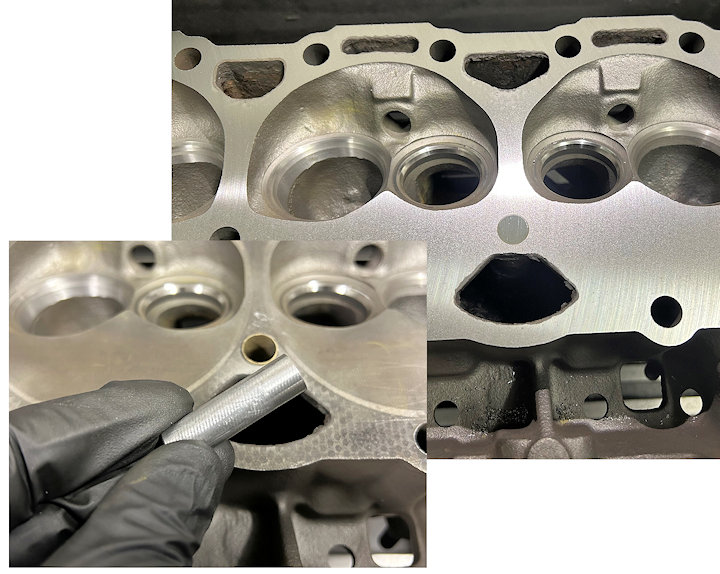

When surfacing heads that have had brass tubes installed in head bolt or pushrod holes, I slip snug aluminum plugs in the tube to support them while cutting. This prevents the cutter bit from grabbing the tube and folding inward. This works great on any application...

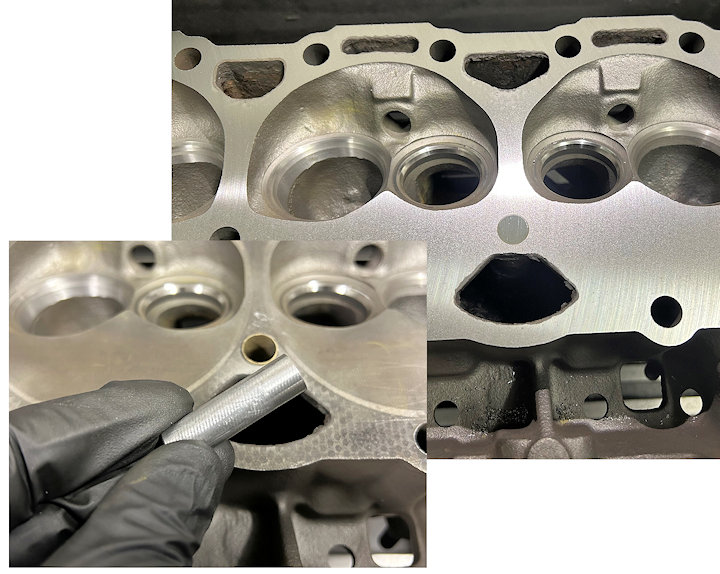

by Donnie Hurt | Oct 1, 2025 | TOOLING

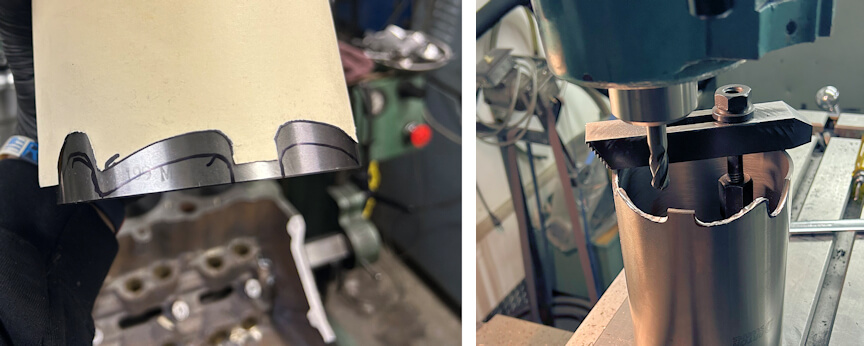

To turn a small block Chevy crank with the damper on, I cut off an old crank snout and remove a few thousandths from the diameter so it would slide inside the damper. Than I can use it along with my crank-turning socket. Sylvain Tremblay Les Ateliers de Moteur...

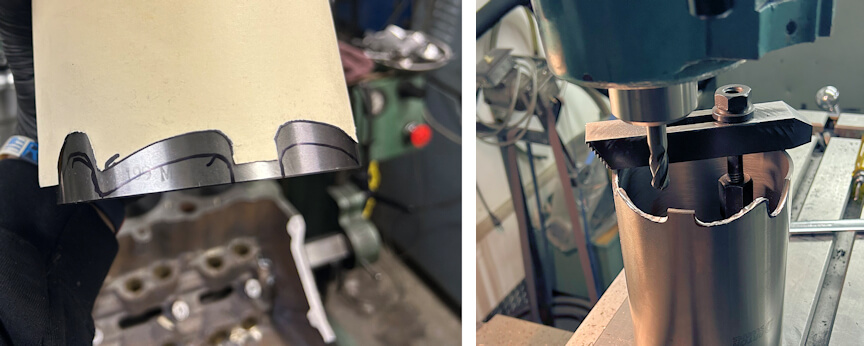

by Donnie Hurt | Jun 4, 2025 | BLOCK WORK

When sleeving blocks that have stroker clearance work done, I make a pattern from the bore ID and transfer it to the sleeve. This allows me to do most of the clearance work to the sleeve before installation using the mill. Find a reference mark on the block and draw...

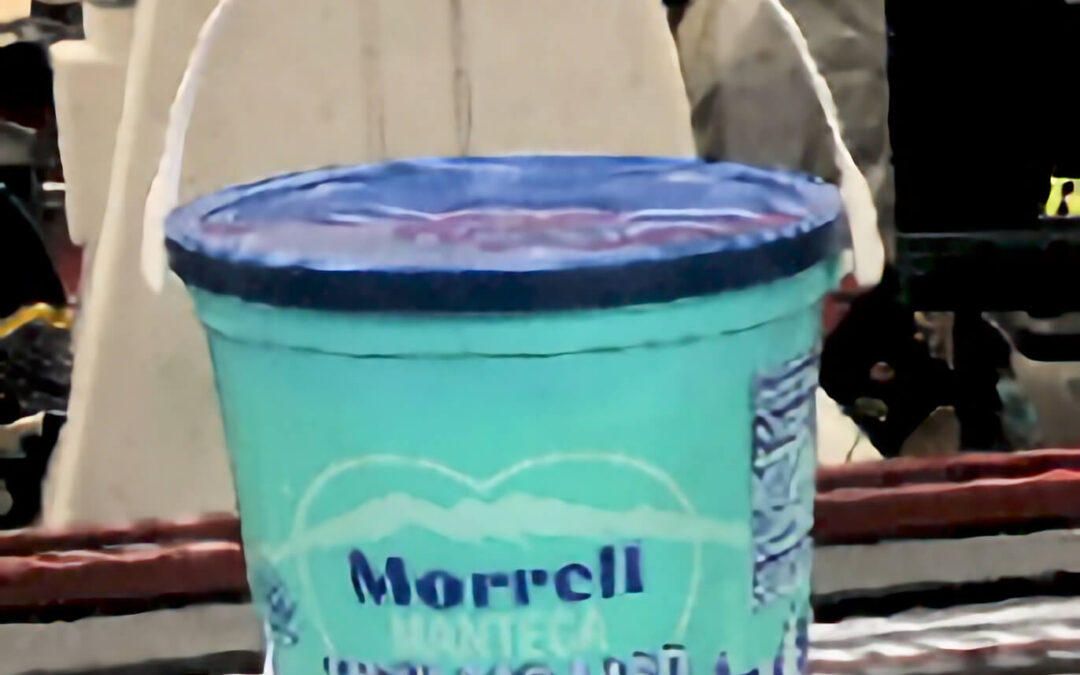

by Donnie Hurt | May 6, 2025 | OTHER SHOP WORK

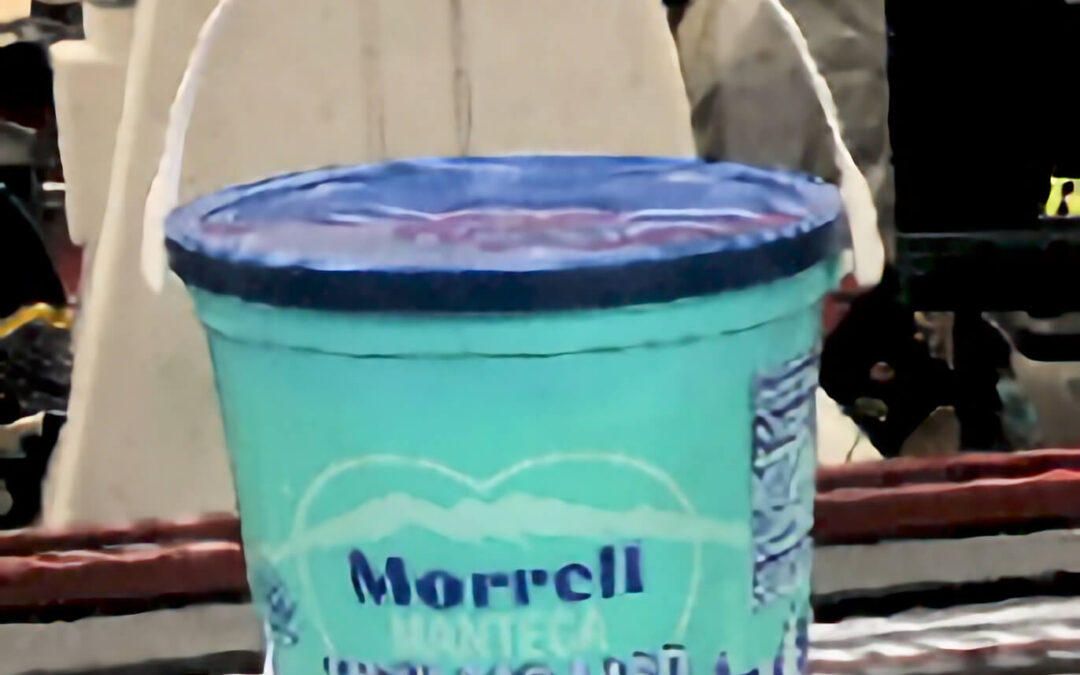

I once worked for Roy Johnson’s Automotive Machine Shop. This is where I was introduced to the use of common cooking lard as a lubricant when drilling on steel. Yes that’s right, now you’re cooking with “Bacon” in the shop. The use of the lard...

by Donnie Hurt | May 6, 2025 | CYLINDER HEADS

When grinding wire for fitting O-rings I use an air angle grinder and put a piece of shim stock between the head and wire to prevent bumping the grinding disc on the freshly machined head. Arus Kinney AK’s Engine and Machining Covington, GA...