by Donnie Hurt | Jan 1, 2026 | LUBRICATION & COOLING

I’ve never trusted aftermarket pan volumes. If you are using the factory dipstick and tube, it’s not an issue, but with aftermarket or locking dipsticks, it’s a guess at best. I set a factory oil pan and the aftermarket pan between milk crates. I put 4...

by Donnie Hurt | Dec 9, 2025 | ASSEMBLY

This is a customer’s balancer, though the procedure will work on a new one with the rubber bonded outer ring. I make a groove that runs down to the center hub. I use a chisel or a cut-off wheel, then I take a pick with yellow paint and mark the line. Should this...

by Donnie Hurt | Dec 9, 2025 | OTHER SHOP WORK

Chamfering a bolt hole might require an extended reach countersink cutter. Here’s how to quickly make an extension for the more common 1/4″ shank cutters. First, drill a 15/32″ x 1″ deep hole in the end of a 6″ length of 3/8″...

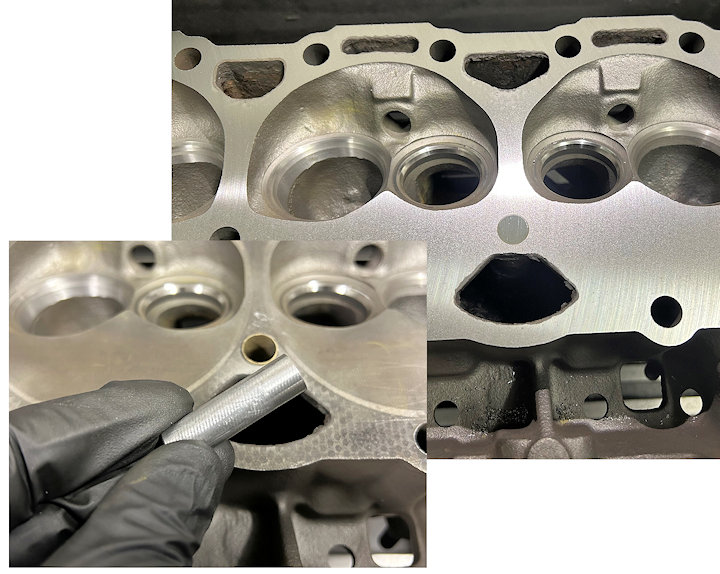

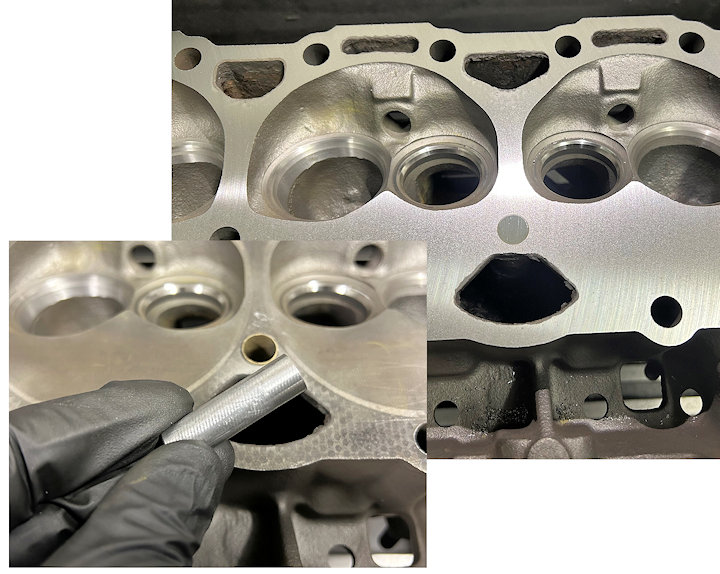

by Donnie Hurt | Dec 9, 2025 | CYLINDER HEADS

When surfacing heads that have had brass tubes installed in head bolt or pushrod holes, I slip snug aluminum plugs in the tube to support them while cutting. This prevents the cutter bit from grabbing the tube and folding inward. This works great on any application...

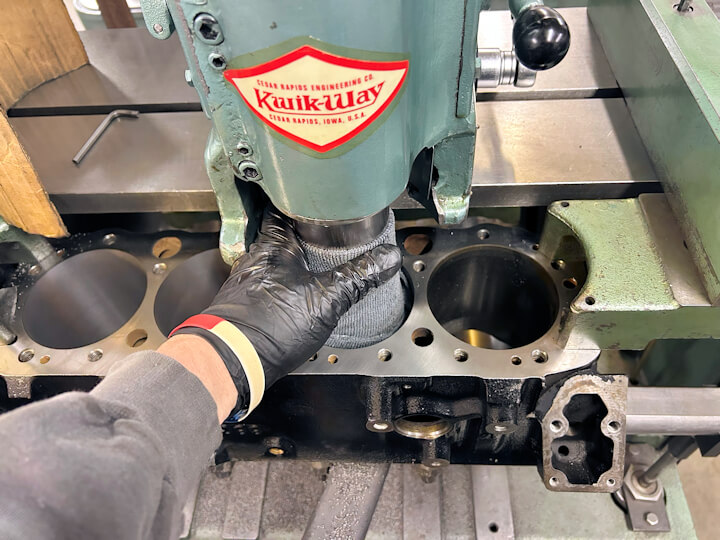

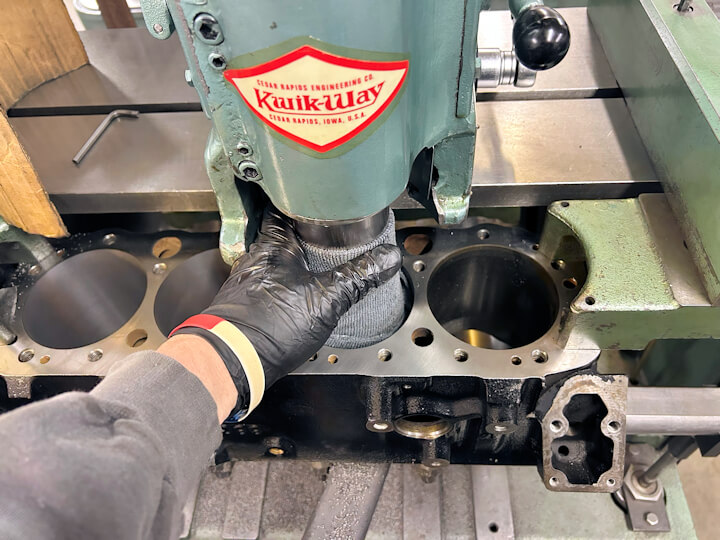

by Donnie Hurt | Nov 24, 2025 | UNCATEGORIZED

When boring blocks, in addition to a cardboard chip deflector and a vacuum cleaner running under it, I still wipe the bar down with a microfiber as it retracts. Just one more way to keep chips out of the column seal. Ron Flood Cedar Machine North Branch,...