by Donnie Hurt | Dec 23, 2024 | CAMSHAFTS & VALVE TRAIN

Typically, most places that grind crankshafts store them on end before and after grinding, but that gets to be difficult when they have pins in the flange. We found that an anti-fatigue mat with holes in it works perfectly to keep them upright. Adney Brown Performance...

by Donnie Hurt | Dec 23, 2024 | CRANKSHAFTS & CONNECTING RODS

If you’re taking an engine apart and are unsure of the cubic inch or the crank stroke, here is a quick way to figure it out. Simply rotate the engine until one piston is at BDC. Take a measurement from the deck of your block down to the deck of the piston. You can use...

by Donnie Hurt | Dec 23, 2024 | CRANKSHAFTS & CONNECTING RODS

When checking and correcting rod straightness, I use two bars against each other in the rod vice. Since the vice isn’t mounted to the cabinet strong enough for most correction work, this allows you to use it. I feel the two bars gives me a better feel for how much I’m...

by Donnie Hurt | Dec 23, 2024 | OTHER SHOP WORK

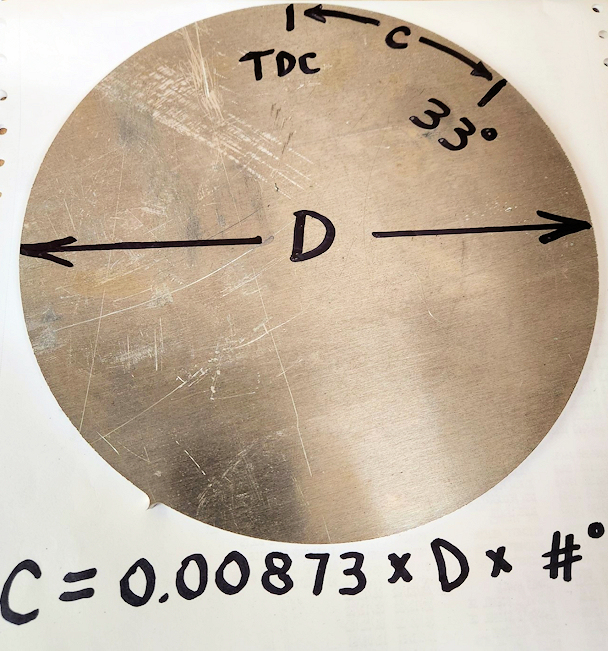

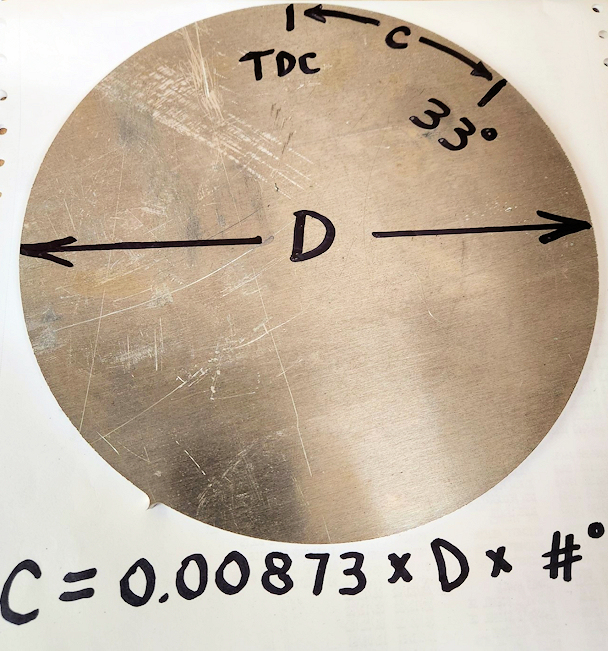

Timing marks on pulleys can be relocated by using the following formula: C = Pulley Diameter x 0.00873 x #° Where: #° = the number of degrees the timing mark is to be moved along the rim of pulley. On pulleys 6″ and greater, with moves of 30° or less, a dial...

by Donnie Hurt | Dec 18, 2024 | BLOCK WORK

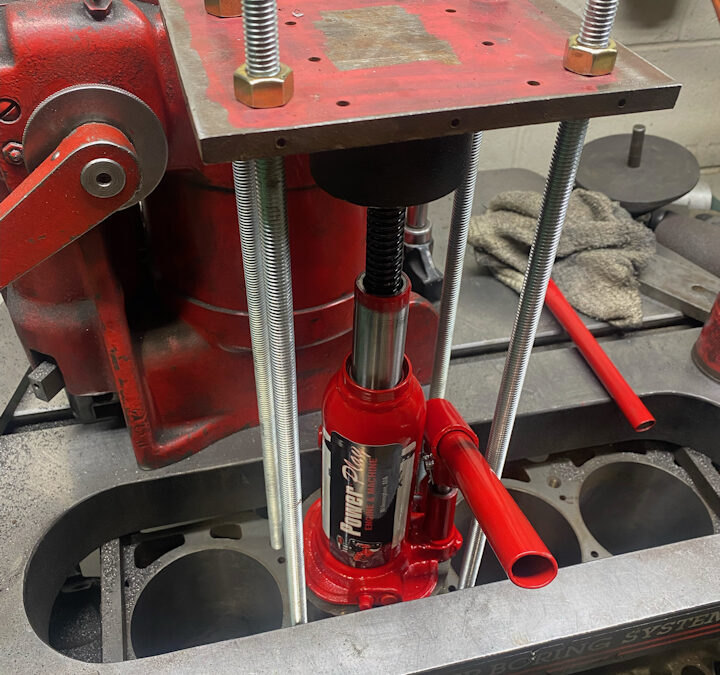

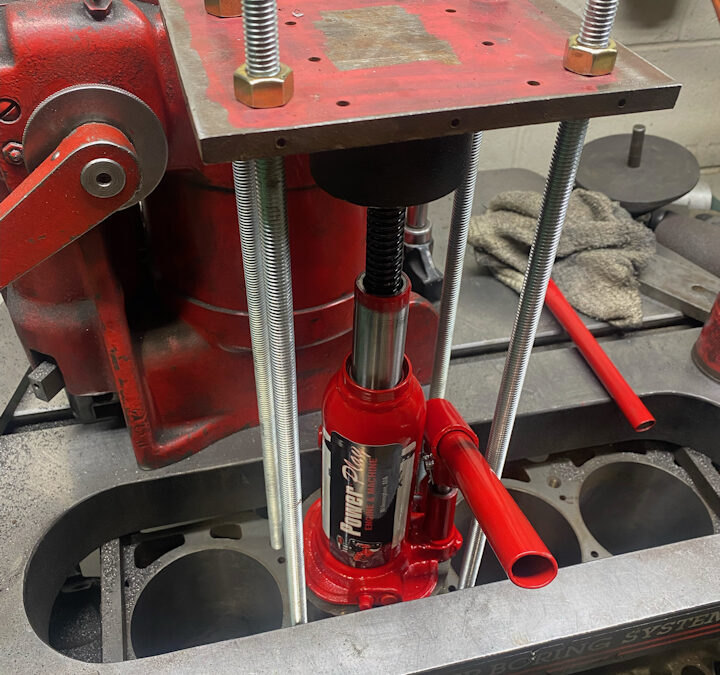

Instead of hammering sleeves in, I made this fixture out of a small bottle jack, threaded rod, and a steel plate. Once the plate is drilled for different blocks it makes the job super-fast, and my arm isn’t sore from swinging the hammer.