by Donnie Hurt | Jun 4, 2025 | BLOCK WORK

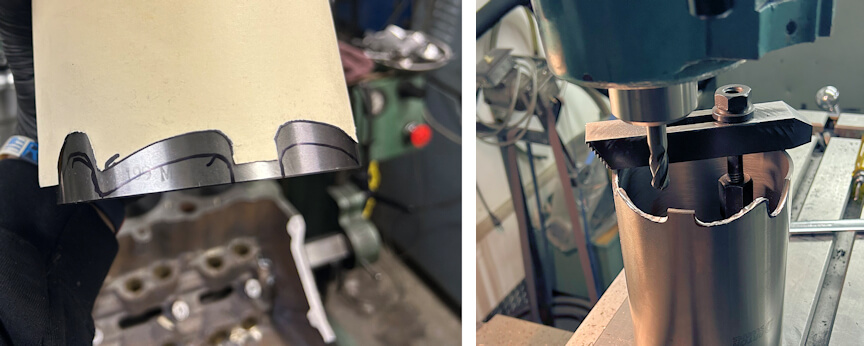

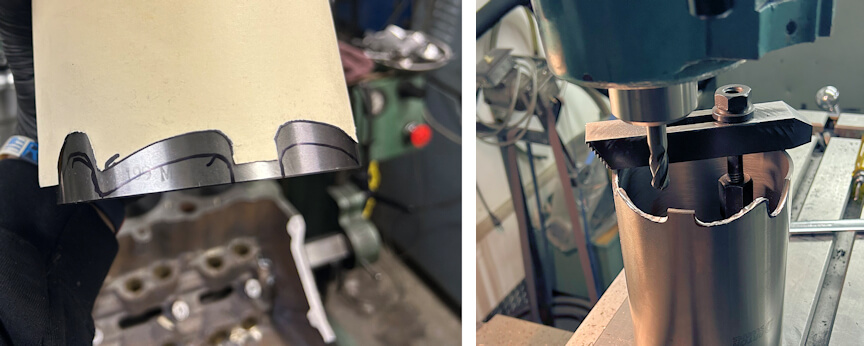

When sleeving blocks that have stroker clearance work done, I make a pattern from the bore ID and transfer it to the sleeve. This allows me to do most of the clearance work to the sleeve before installation using the mill. Find a reference mark on the block and draw...

by Donnie Hurt | Jun 4, 2025 | TOOLING

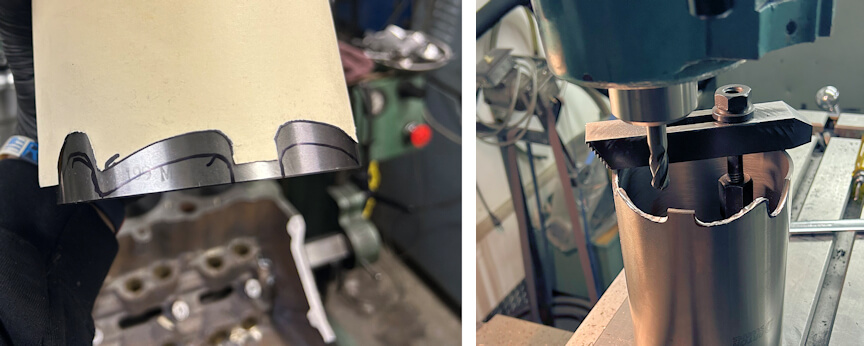

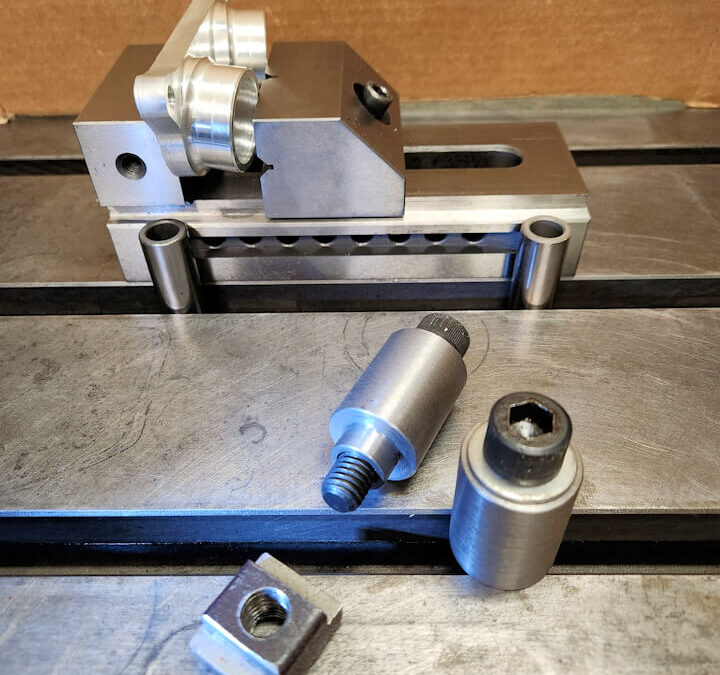

Use dowel pins or wrist pins that fit snug in your mill’s T-slots to quickly tram or align a cylinder head, engine block, or vise. (shown using 18mm wrist pins). Also shown above is an alternative method. These simple to machine stepped pins, which fit snug in...

by Donnie Hurt | Jan 15, 2025 | CYLINDER HEADS

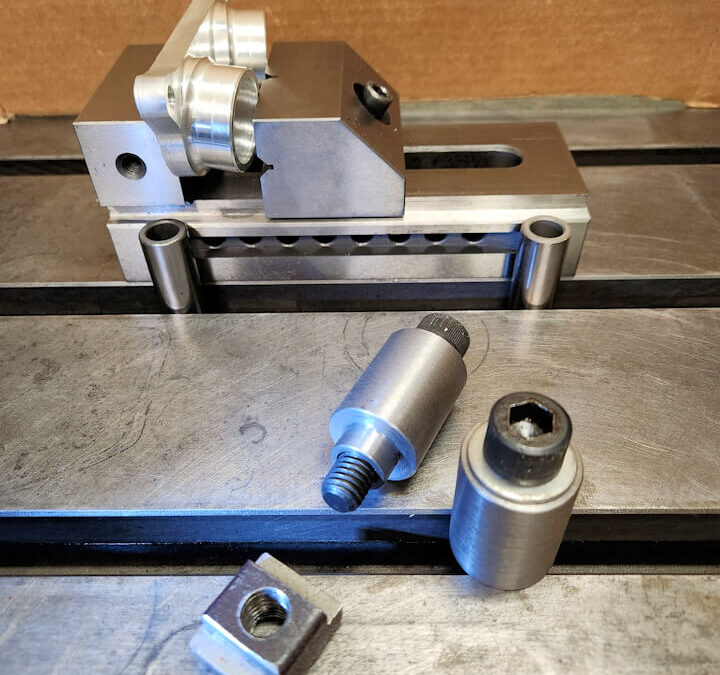

On race engine cylinder heads that have exotic seat angles, I like to leave myself notes for future reference on freshen ups. I do keep a lot of notes in my folders and build sheets, but I found it handy to scribe the valve seat angles under the cylinder heads (kind...

by Donnie Hurt | Nov 5, 2024 | DISASSEMBLY & CLEANING

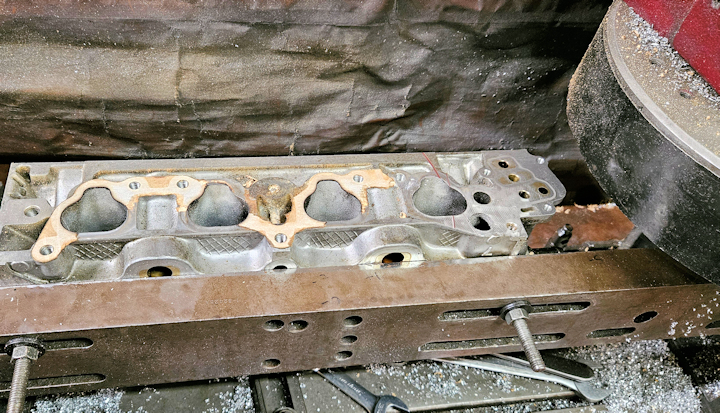

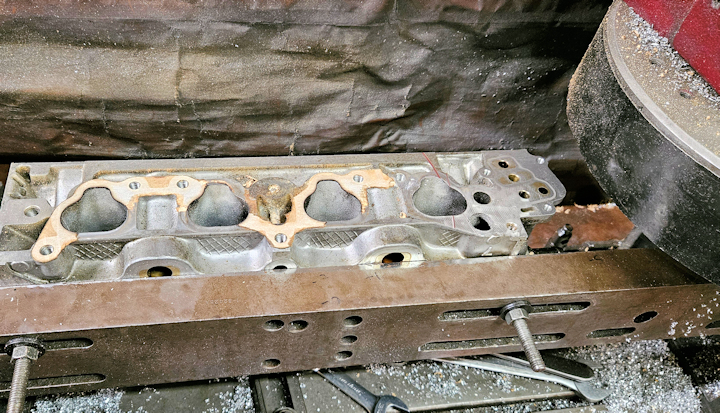

Honda intake gaskets are extremely difficult to remove. I don’t know what these things are made out of, but they can become permanently bonded to the intake surface of the heads. Instead of spending hours trying to scrape these things off and ending up leaving...

by Donnie Hurt | Nov 5, 2024 | OTHER SHOP WORK

When chucking a long workpiece in your lathe, such as bar stock used to make custom valve guides, it’s imperative to support the far end inside the spindle. Commercial spindle liners are available but can be costly or you may not have the exact size needed on hand....