by Donnie Hurt | Jun 4, 2025 | BLOCK WORK

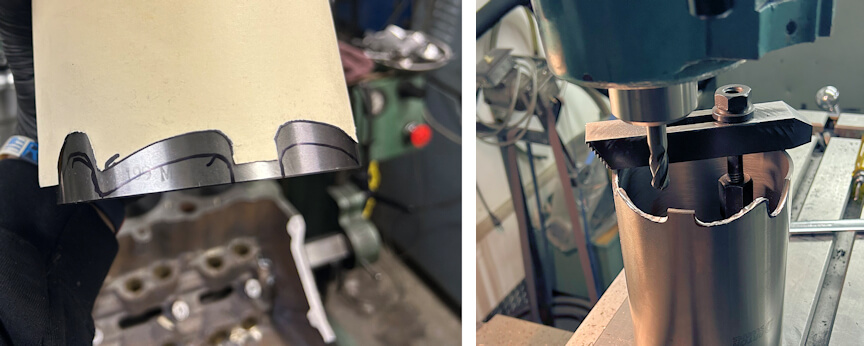

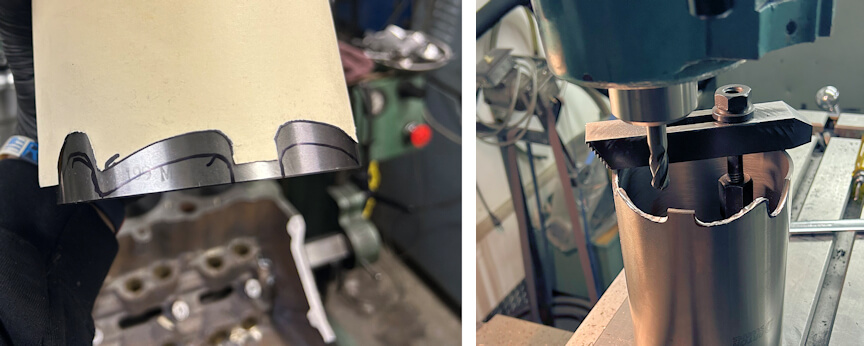

When sleeving blocks that have stroker clearance work done, I make a pattern from the bore ID and transfer it to the sleeve. This allows me to do most of the clearance work to the sleeve before installation using the mill. Find a reference mark on the block and draw...

by Donnie Hurt | Jun 4, 2025 | TOOLING

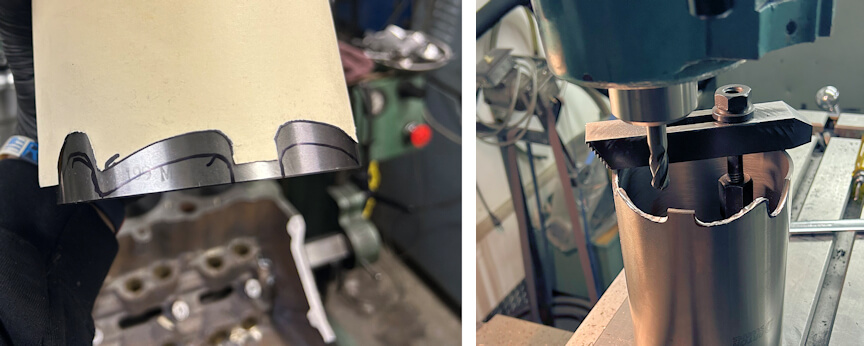

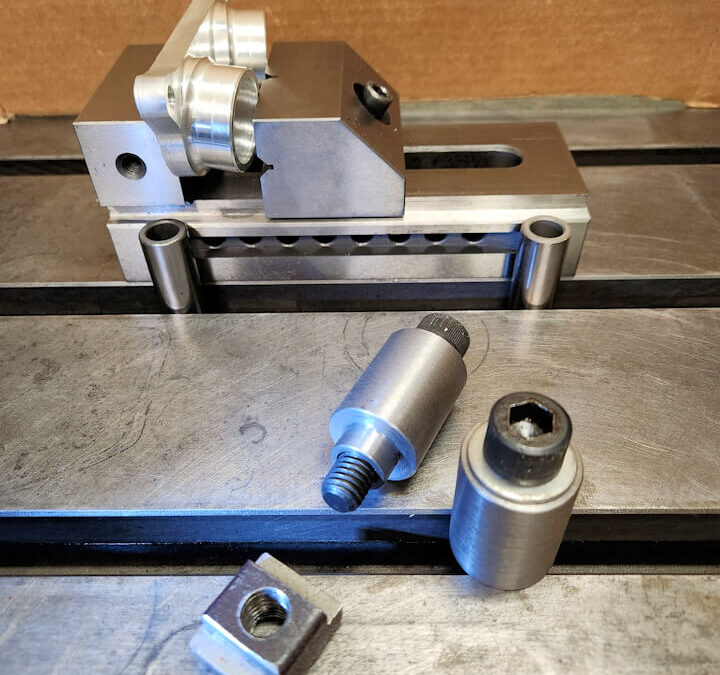

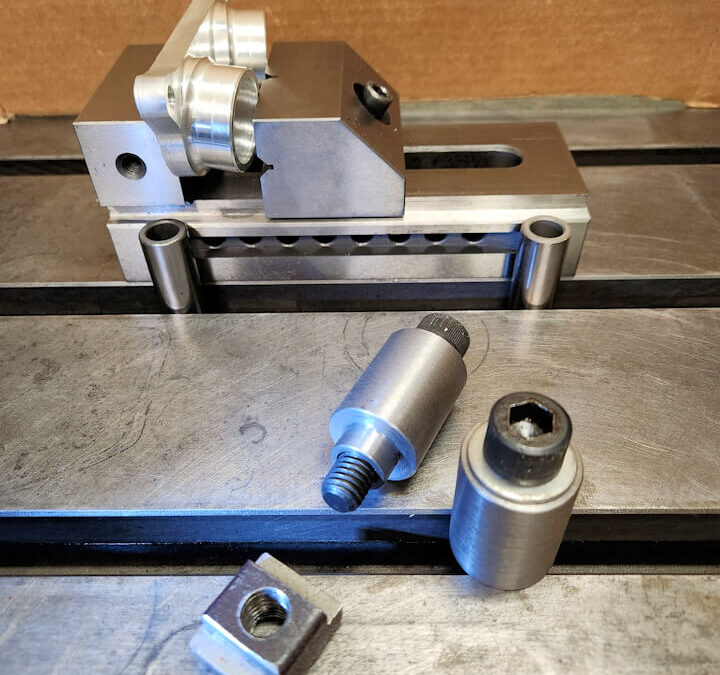

Use dowel pins or wrist pins that fit snug in your mill’s T-slots to quickly tram or align a cylinder head, engine block, or vise. (shown using 18mm wrist pins). Also shown above is an alternative method. These simple to machine stepped pins, which fit snug in...

by Donnie Hurt | Jun 4, 2025 | CYLINDER HEADS, UNCATEGORIZED

The person who taught me to broach bronze liners used hose clamps, but sometimes they crack. More often it’s when it has had a .502” service guide installed. So instead of hose clamps, I bought some inexpensive split collars for 1/2″. A person could machine them...

by Donnie Hurt | May 6, 2025 | OTHER SHOP WORK

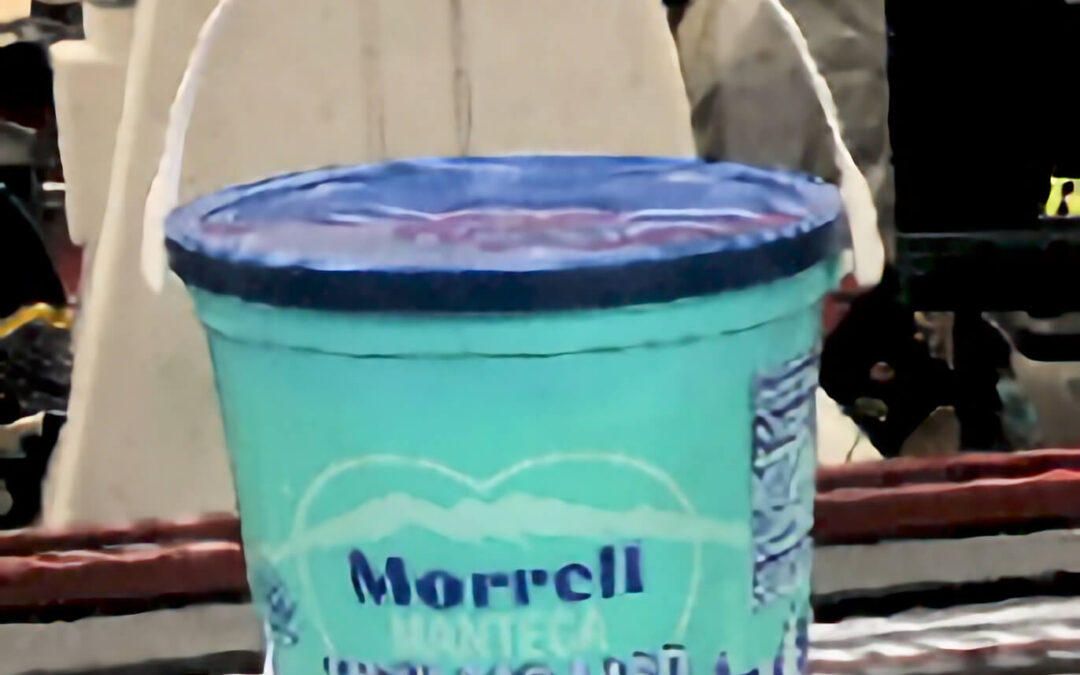

I once worked for Roy Johnson’s Automotive Machine Shop. This is where I was introduced to the use of common cooking lard as a lubricant when drilling on steel. Yes that’s right, now you’re cooking with “Bacon” in the shop. The use of the lard...

by Donnie Hurt | May 6, 2025 | CYLINDER HEADS

When grinding wire for fitting O-rings I use an air angle grinder and put a piece of shim stock between the head and wire to prevent bumping the grinding disc on the freshly machined head. Arus Kinney AK’s Engine and Machining Covington, GA...