by Donnie Hurt | Jan 18, 2018 | OPERATIONS

POSITIVE LANGUAGE INCREASES SALES We all need some positive reinforcement from time to time. When talking with your customers about some news that is not necessarily good, you can also put a more positive spin on the news. Let’s say you are starting an engine build...

by Donnie Hurt | Jan 5, 2018 | LUBRICATION & COOLING

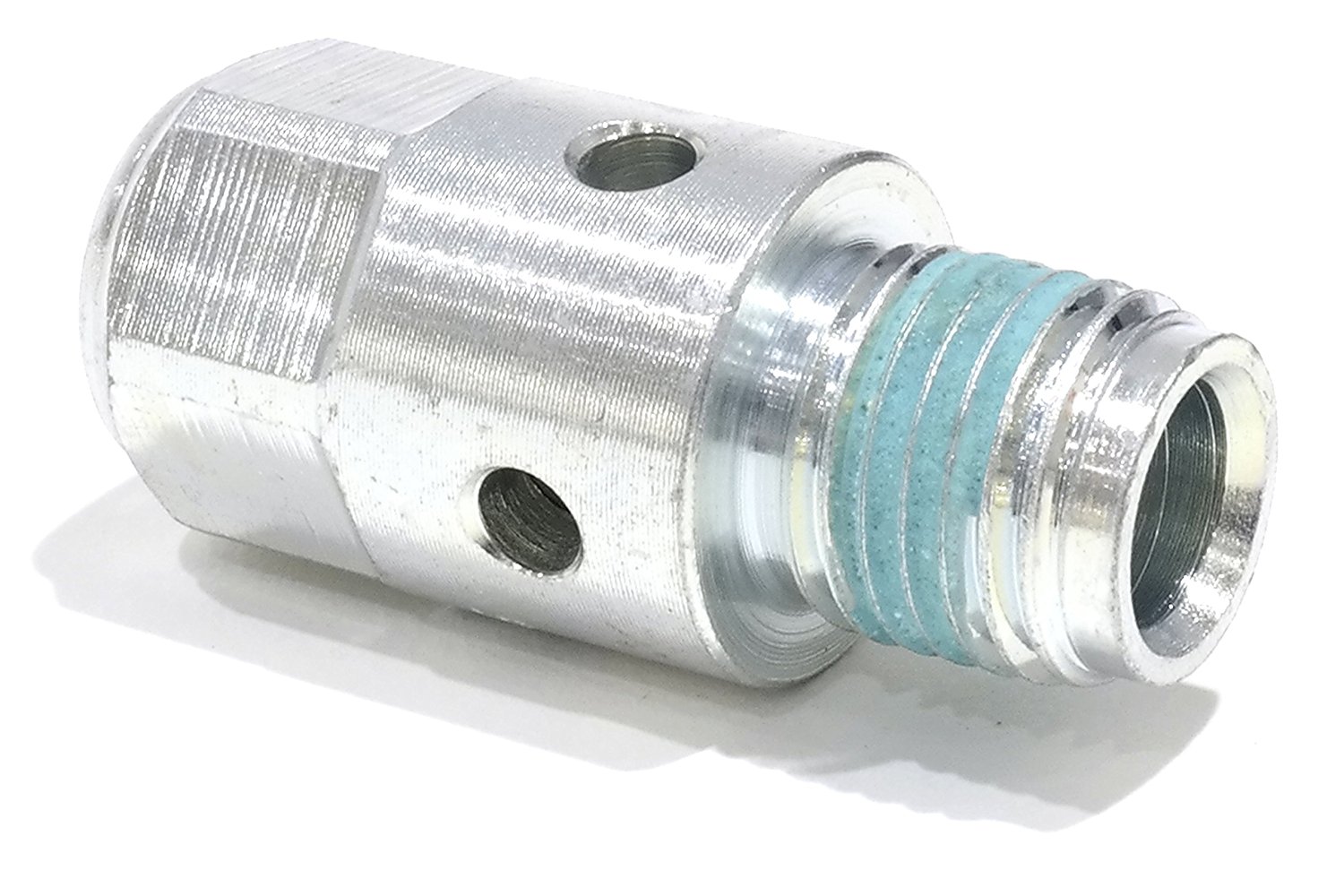

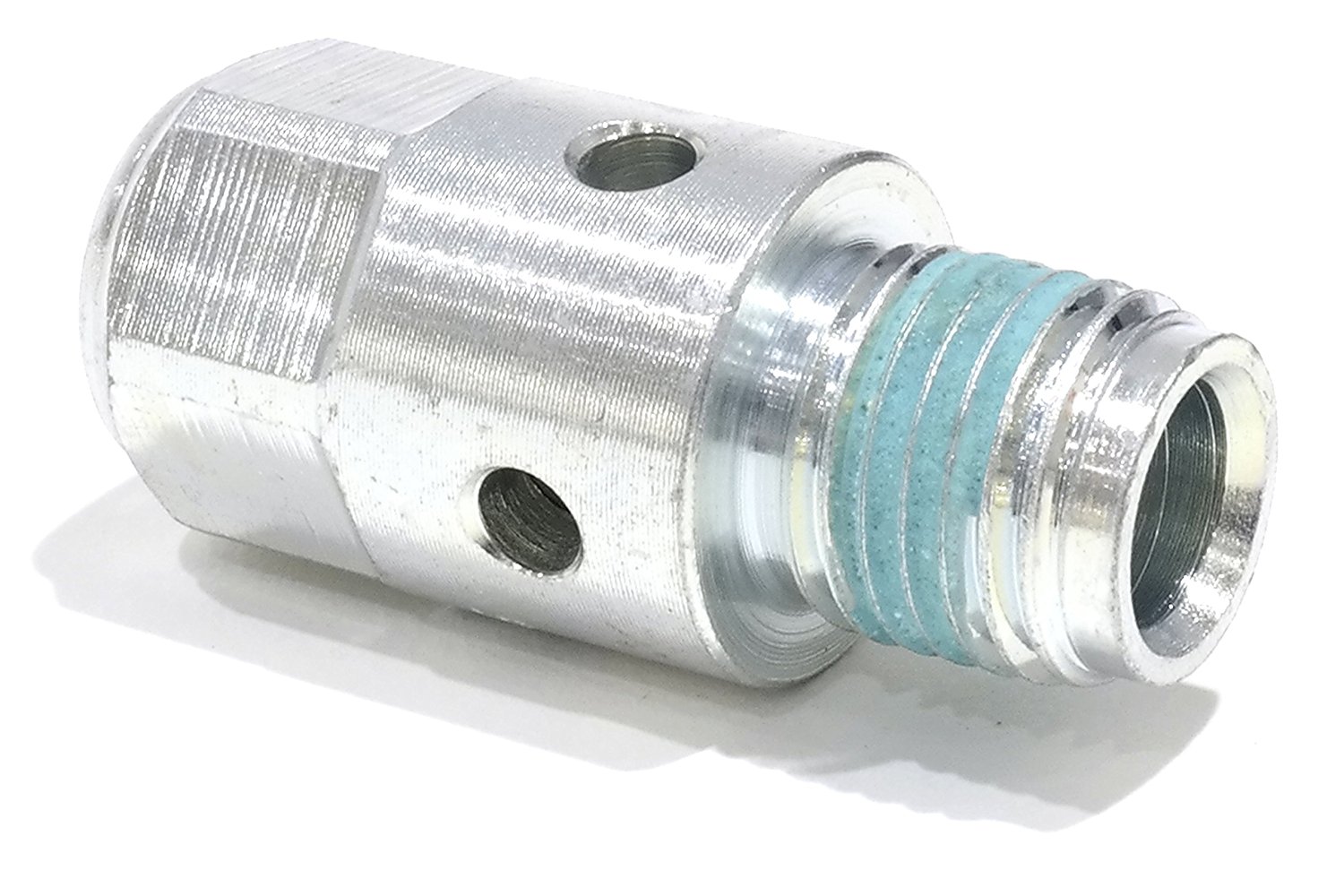

GM LS OIL PRESSURE PROBLEMS We had rebuilt a customer’s 5.3L GM engine but they were still complaining of low oil pressure at idle. We sent them a new oil pump, but it still was low, about 17lbs at idle. We learned that there was a second oil pressure relief valve in...

by Donnie Hurt | Jan 4, 2018 | BLOCK WORK

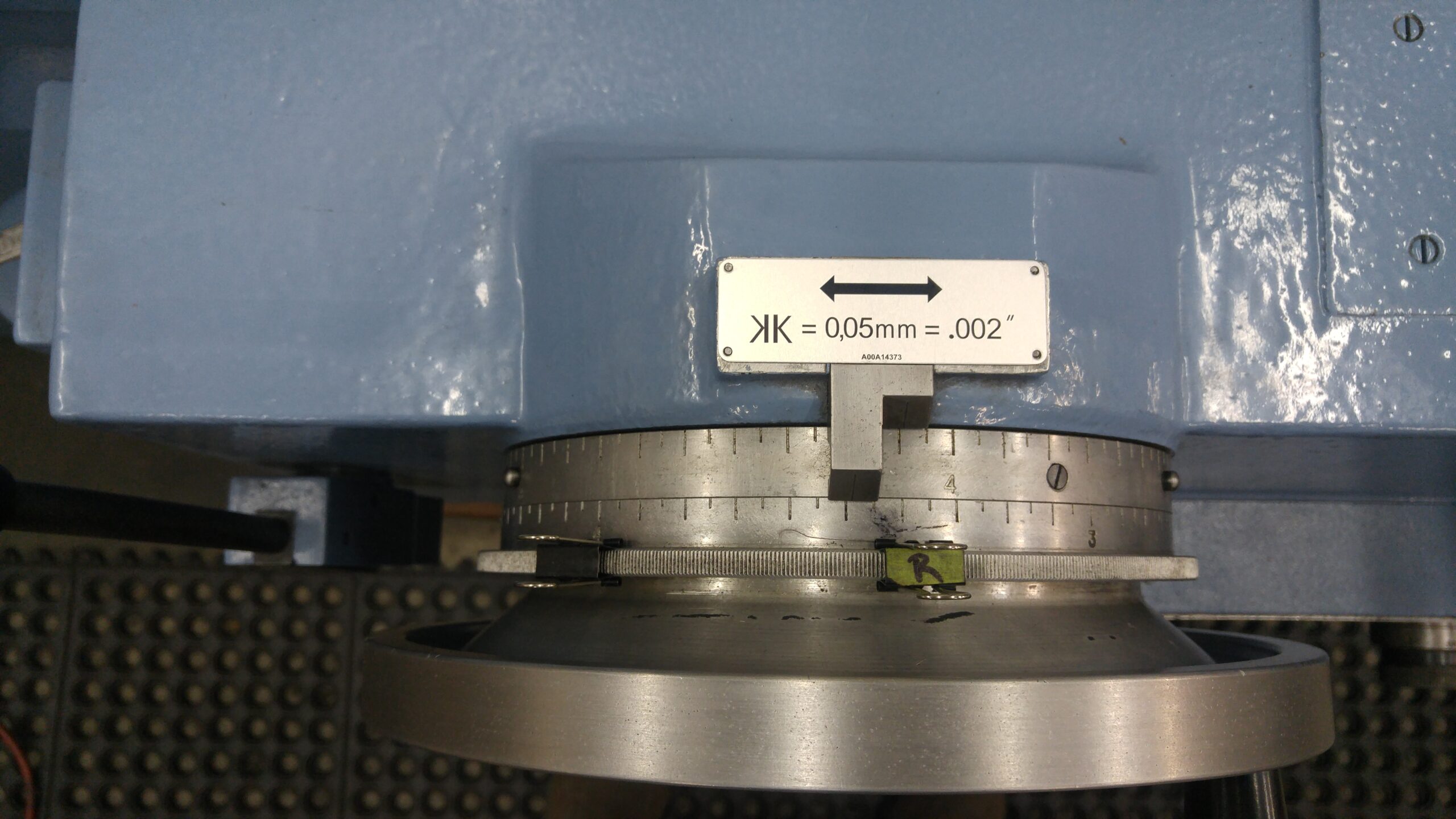

HARLEY JUG JIG This jig was made to hold Harley cylinders and torque plates in your Sunnen hone. It allows you to set up cylinders vertically, then pivots for hand held hone while using honing oil from your hone. It is much faster and safer than holding cylinders by...

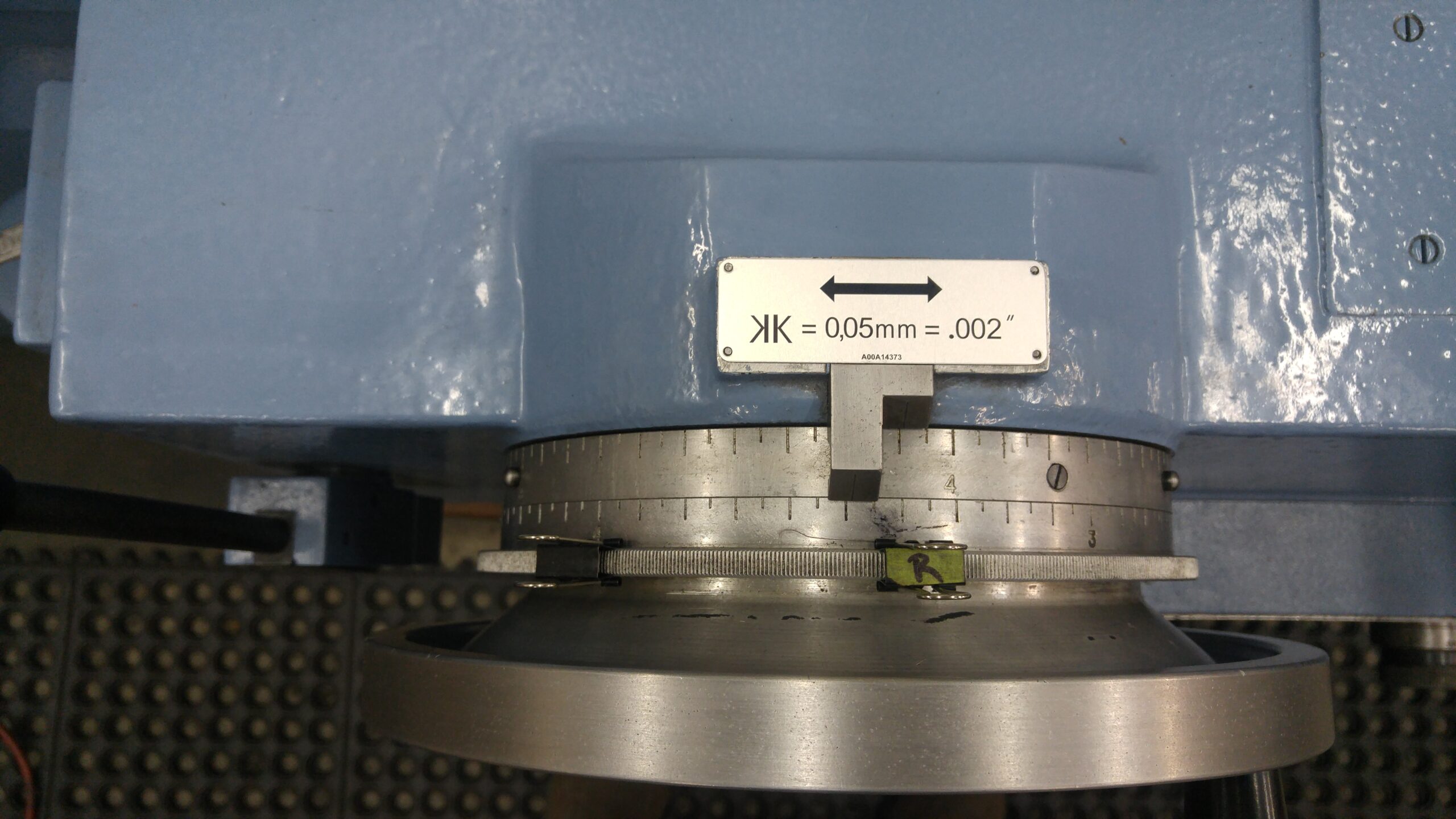

by Donnie Hurt | Jan 4, 2018 | CRANKSHAFTS & CONNECTING RODS

MARK THE SPOT When grinding cranks I like to know where the thrust, radius or the crank cheek is. Once I clean up that side, a simple paper clamp marks that and is a good guide on how close that surface or radius is when sweeping for final size. It works for me. Randy...

by Donnie Hurt | Dec 1, 2017 | DISASSEMBLY & CLEANING

CLEANING INTAKE PORTS After porting an intake manifold or a set of heads, there is going to be quite a bit of sand, aluminum, and other things in the port. It is very important that all of this debris gets cleaned out before assembling the engine. An easy and...