by Donnie Hurt | May 1, 2017 | TOOLING

BLAST IT We’ve all had problems with plain shank tooling “turning” in a key-less chuck. I have found that bead blasting the end of the tooling where it goes in the chuck can provide enough grip and end the spin. Dale Beran The Parts Bin Ord, NE May,...

by Donnie Hurt | Apr 1, 2017 | LUBRICATION & COOLING

CK-4 Diesel Update Recently diesel engine oils changed from the decade old CJ-4 formulation to the new CK-4 formulation. While intended to be an upgrade, the new CK-4 formulation has been met with resistance and even an outright “do not use” warning from Ford Motor...

by Donnie Hurt | Apr 1, 2017 | OTHER SHOP WORK

ELECTRIC ENGRAVING TOOL In our shop we use our TIG welder to remove broken exhaust manifold mounting studs from the exhaust side of cylinder heads. For setup we use DC straight polarity with high frequency start, a sharp tungsten electrode protruding about 3/8 inch...

by Donnie Hurt | Apr 1, 2017 | CYLINDER HEADS

DON’T BUST THAT GUIDE If you’ve been having problems breaking off the end of a valve guide, on the spring end of the guide, when installing thin wall guides, I may have a solution. I machine from the spring cup side of the head instead of the valve seat side. You will...

by Donnie Hurt | Apr 1, 2017 | OTHER SHOP WORK

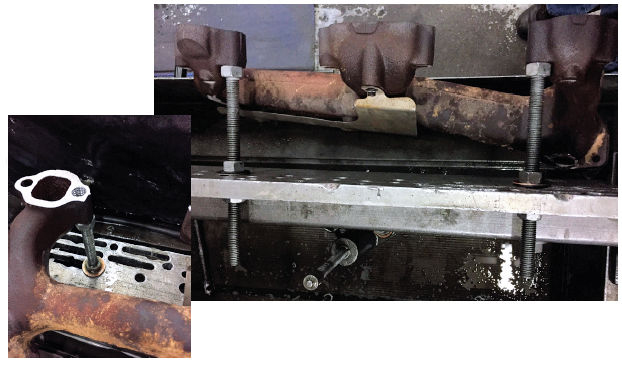

MANIFOLD MOUNT Exhaust manifolds can be resurfaced using a surface grinder with the typical universal cylinder head fixture. First start by tapping threads in the thru holes. I have 1/2”, 9/16”, 5/8” & 3/4” All-thread pieces cut to 8” or so, that I screw into the...