by Donnie Hurt | Mar 21, 2025 | CYLINDER HEADS

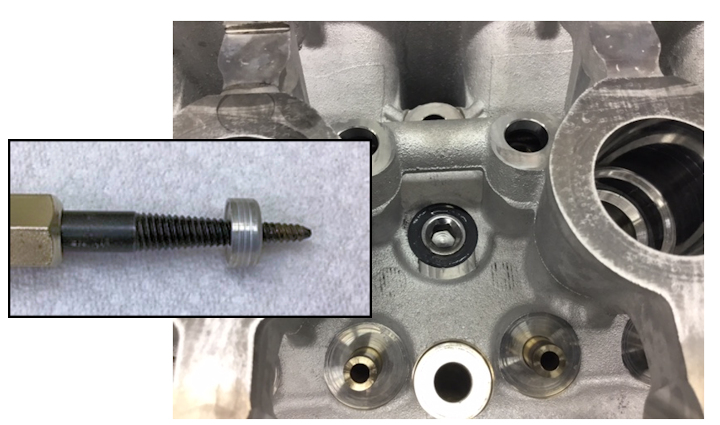

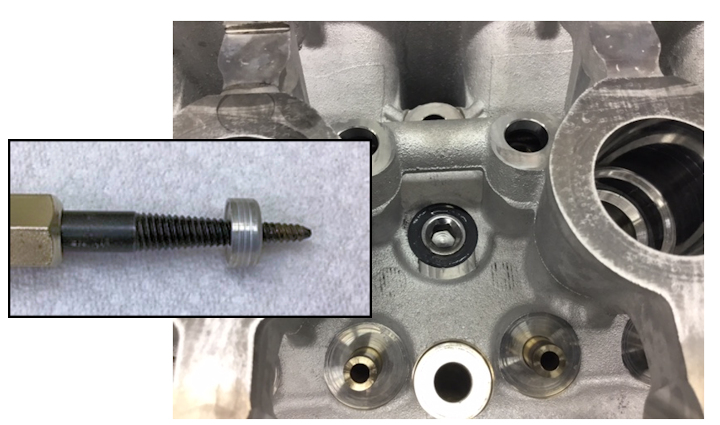

If you work on Mini Cooper heads, it is important to replace the aluminum plugs, especially if the head has been overheated. These are notorious for popping out after the head has been reinstalled. It’s an easy fix with a tapered 3/8 npt plug that is .462” deep....

by Donnie Hurt | Mar 21, 2025 | TOOLING

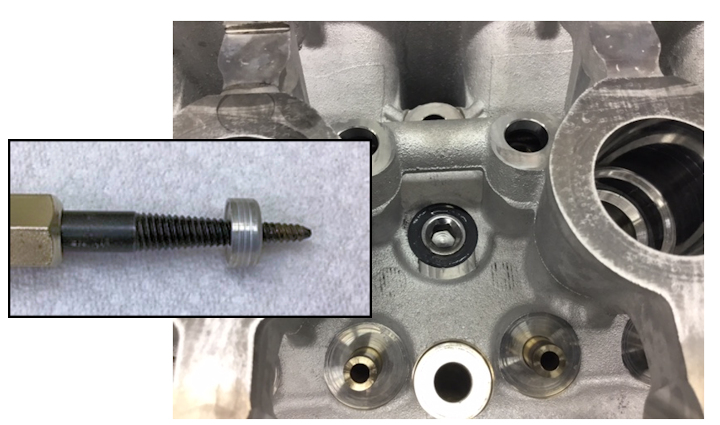

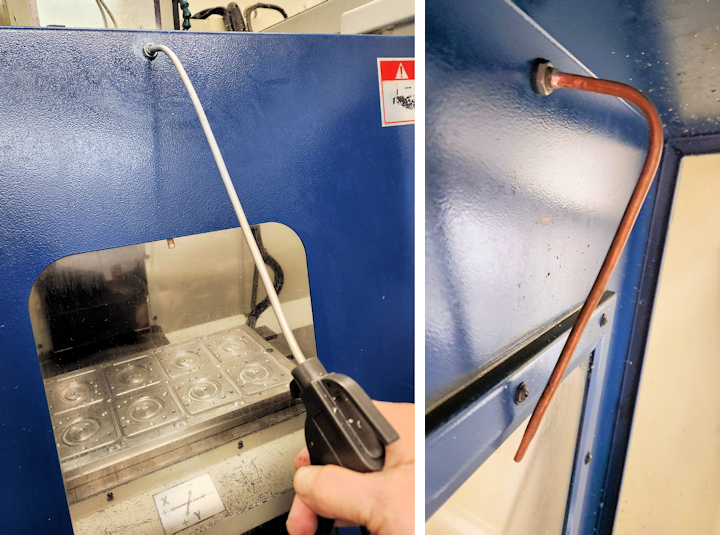

Often, you cannot see through your CNC mill’s cabinet window because coolant is splashing on the inside of the window. Rather than create a mess by opening the door to take a peek, install this simple window air blast tube. Your parts list will include a...

by Donnie Hurt | Mar 4, 2025 | DISASSEMBLY & CLEANING

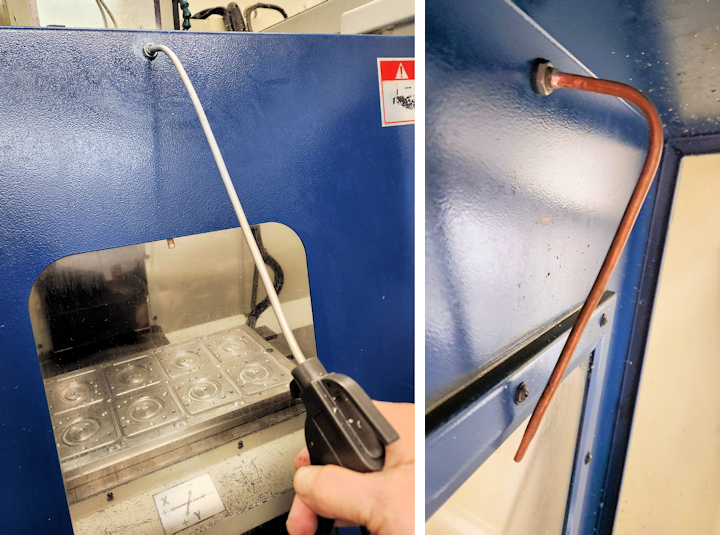

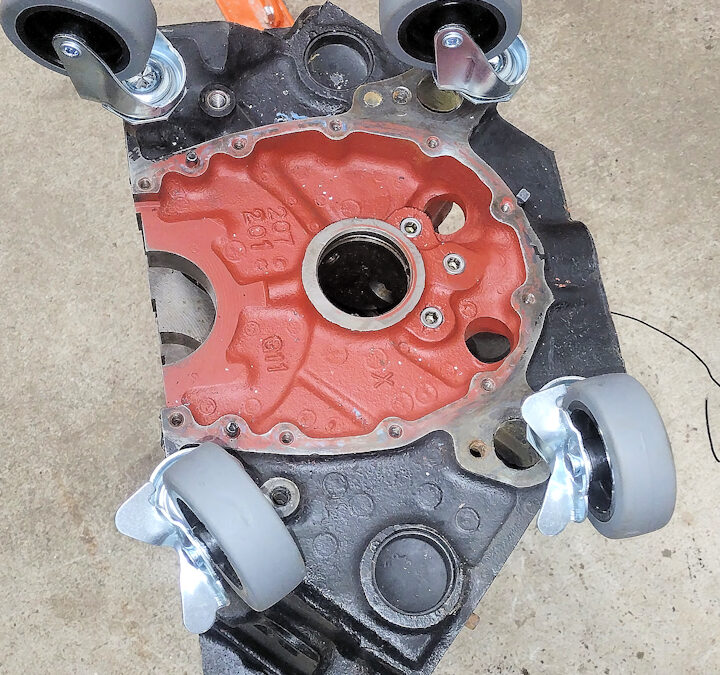

I have a never-ending pile of cores being moved around the shop from here to there. I use threaded stud casters to roll them out of the way. These have a 3/8-16 stud, but I also have them in M10 to fit LS blocks and can be used in the bell housing side as well. And...

by Donnie Hurt | Mar 4, 2025 | GASKETS & SEALING

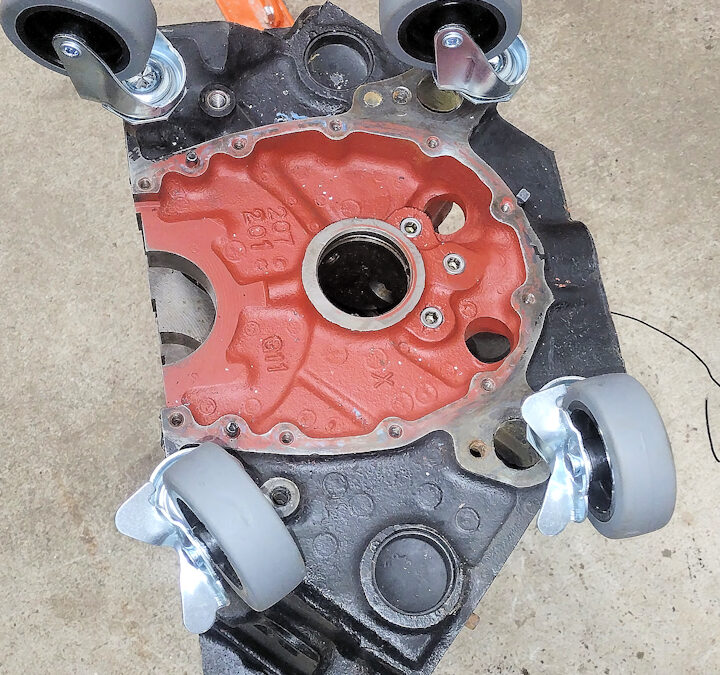

When deciding how much to mill an intake manifold for “fit”, I use cardboard shims. Most gaskets are .060 compressed, and if the intake fits great with, say, a .020 shim, then a .040 removal is needed. At that point, I also check the ends for fit. Machine once, wash...

by Donnie Hurt | Feb 20, 2025 | TOOLING

Time is money and it helps to know where your tooling cuts, especially when it’s some that isn’t used every day. I use note cards, the back of my business cards, or tape to write myself notes for the next time I grab that tooling. Randy Torvinen Torvinen’s Machine...