by Donnie Hurt | Feb 1, 2016 | CRANKSHAFTS & CONNECTING RODS

ANOTHER DOWEL PULLER We were trying to remove the alignment dowels from some “H” beam rods and our usual method of using a head dowel puller wasn’t working on the stubborn ones. I was trying to figure out a more precision collet set to use when I decided that my mill...

by Donnie Hurt | Jan 1, 2016 | PISTONS & RINGS

MINI GROOVES AND ACCUMULATOR GROOVES EXPLAINED Piston ring second land accumulator grooves provide an area for escaping combustion gases and crankcase pressures, that get past the piston rings, to gather and dissipate. Without this feature, the passing compression...

by Donnie Hurt | Jan 1, 2016 | CYLINDER HEADS

HD GUIDE REPLACEMENT On older Harley Davidson Pan, Shovel, Ironhead and many other cylinder heads, flanged guide removal can lead to damage to the host bore in the head. Many times the guide is distorted and will tear up the bore as it passes back through. To stop...

by Donnie Hurt | Jan 1, 2016 | GASKETS & SEALING

REAR MAIN SEAL SEAL I use RTV on the back side of most rear main seals. This is a great safety measure on rubber seals and a must on early rope rear main seal style blocks when using a neoprene type conversion seal. Splitting the alignment of the seal to block is...

by Donnie Hurt | Jan 1, 2016 | OTHER SHOP WORK

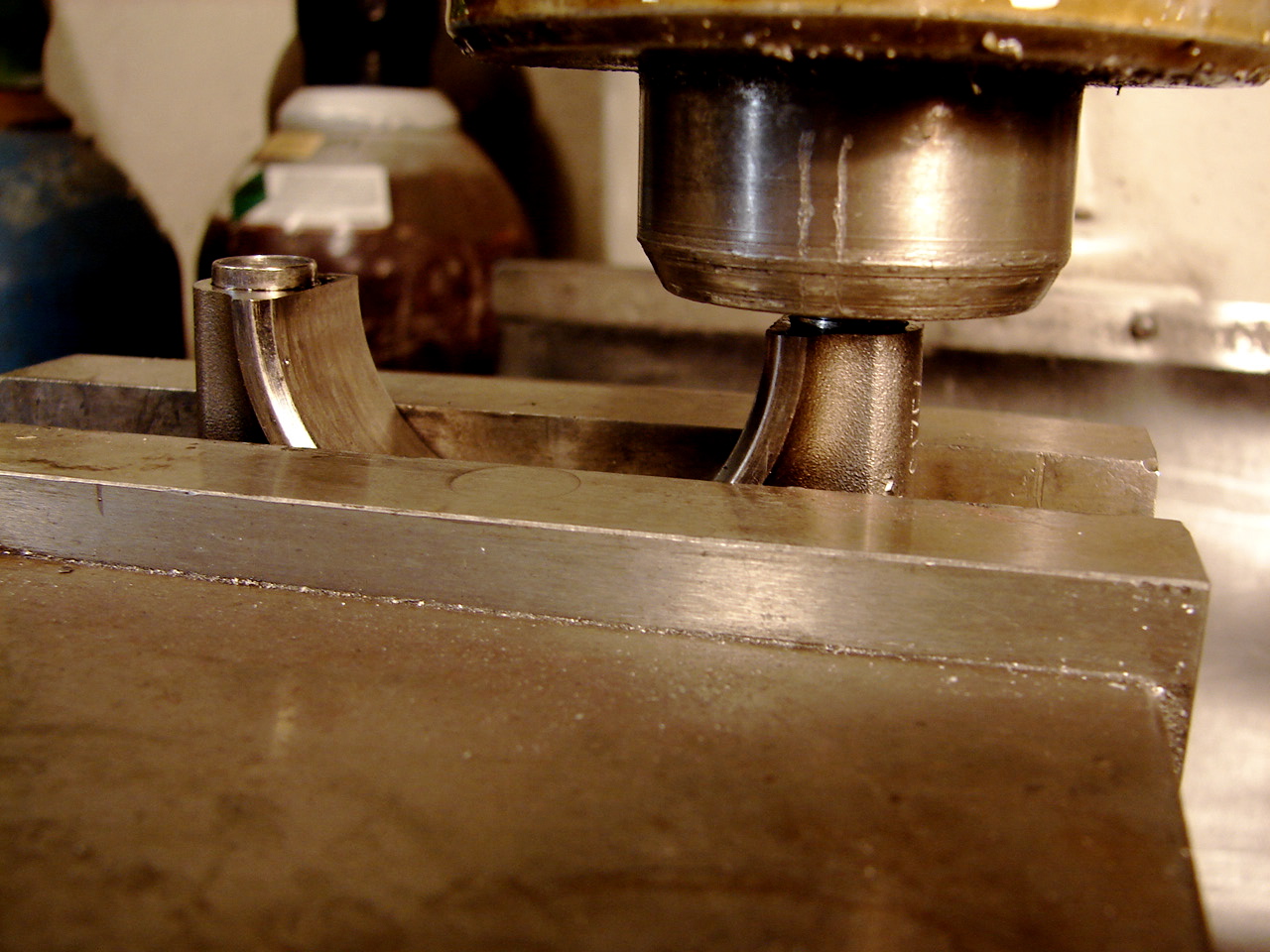

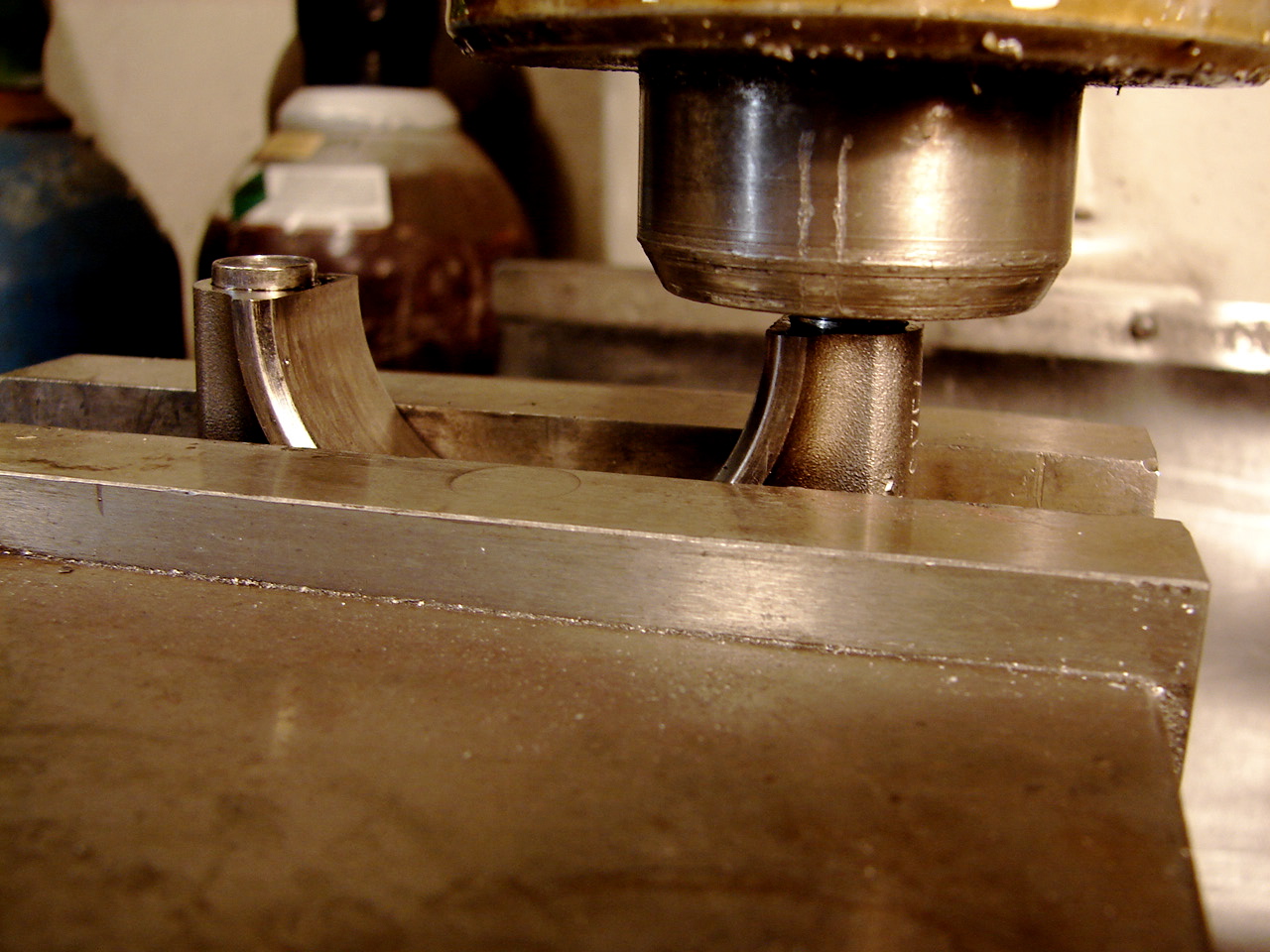

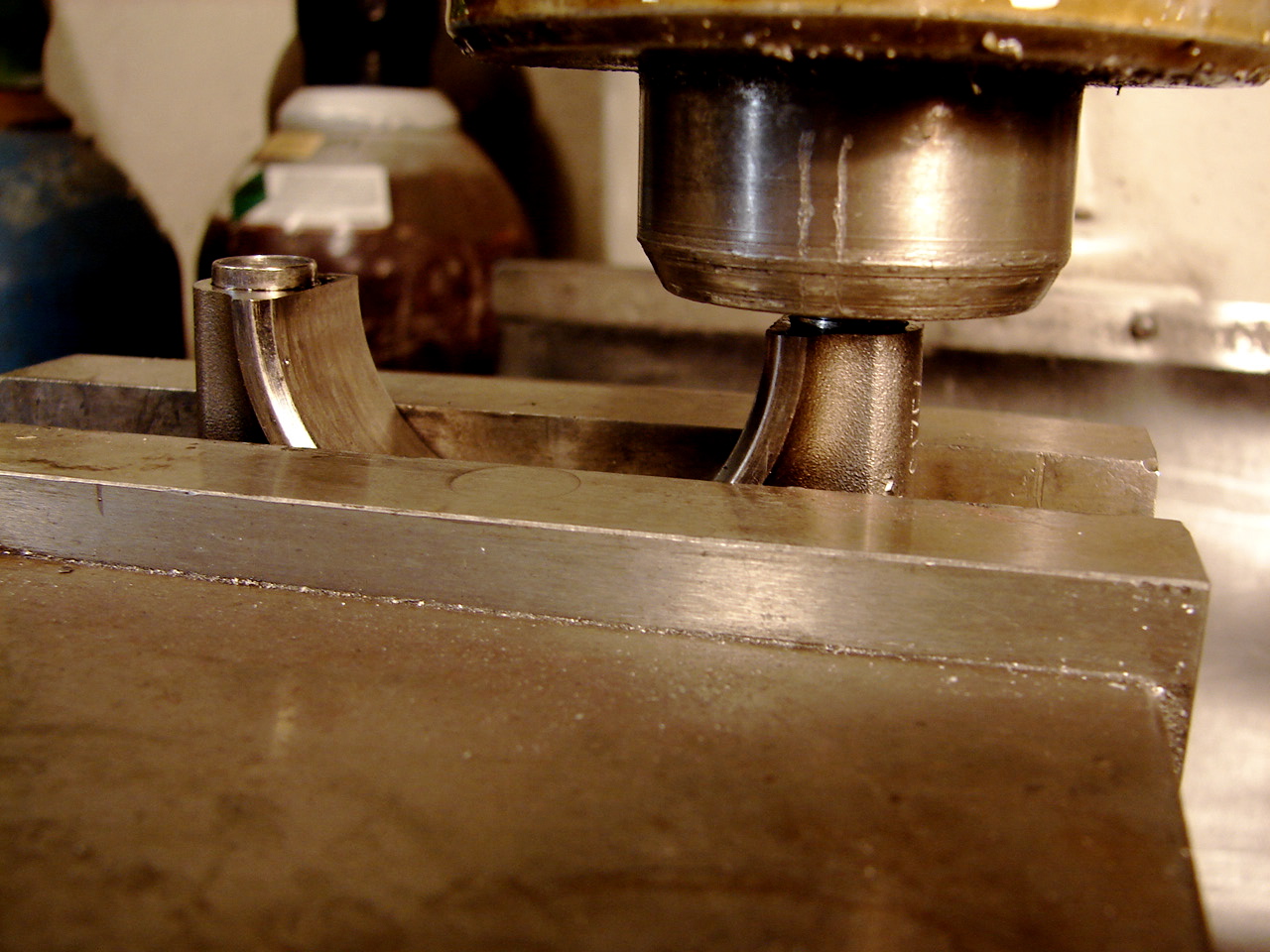

HEAD SHOP AS A MILL When we need to plunge mill or drill an irregular object, such as when removing a broken bolt or stud in a motorcycle part, we use our seat and guide machine to hold and locate the part. The air clamp, air float and roll over fixture make short...