by Donnie Hurt | May 1, 2022 | OTHER SHOP WORK

STRAIGHTENING WITH STUDS Smaller crankshafts and camshafts are so “springy” they can resist straightening and can be hard to straighten by peening. I prefer to use a peening technique on all the crankshafts and camshafts that come through the shop. When on the...

by Donnie Hurt | May 1, 2022 | CYLINDER HEADS

FALSE SEAT I.D. When trying to determine if an iron head has a false seat ring in, we have found the fastest method is to mag-check the head. If it has a false seat in it, you will know instantly. Adney Brown Performance Crankshaft Ferndale, MI ...

by Donnie Hurt | May 1, 2022 | OPERATIONS

CLEARLY CURTAINS Due to a recent addition of shop equipment, all our machines were moved to make room. To help keep close or neighboring machines from getting each other dirty from flying debris, I used an inexpensive shower liner as a wall between them. Hung with a...

by Donnie Hurt | Apr 1, 2022 | OPERATIONS

BEFORE COVID AND BEYOND Way before the Covid virus I was concerned with getting infection by customary handshaking. I was cutting or scraping my hands on a regular basis in the shop. To keep any germs from entering my body I used the “newskin” liquid bandage to seal...

by Donnie Hurt | Apr 1, 2022 | BLOCK WORK

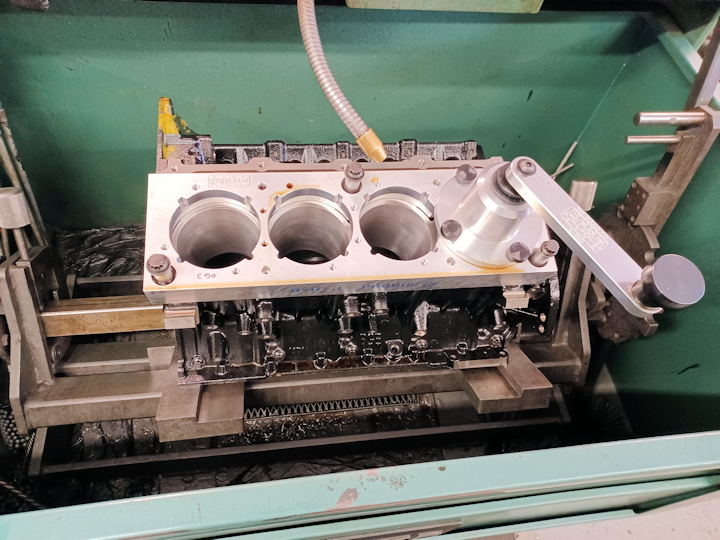

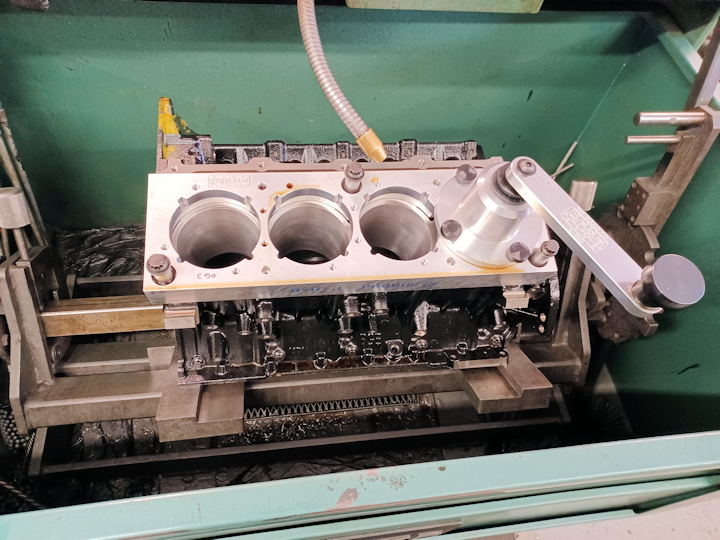

CLEAN CUT When cutting O-ring and receiver grooves for top fuel hoops, it’s important to have plenty of cutting oil to get a nice clean cut in the heads and block. Instead of spraying penetrating oil all over the bench, we do them in the honing tank and flood the work...