by Donnie Hurt | Dec 1, 2021 | TOOLING

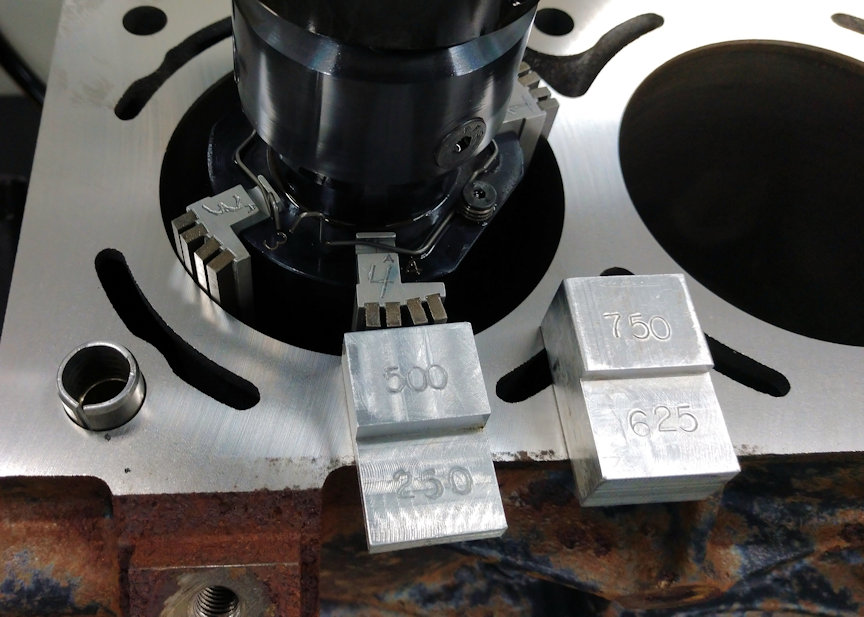

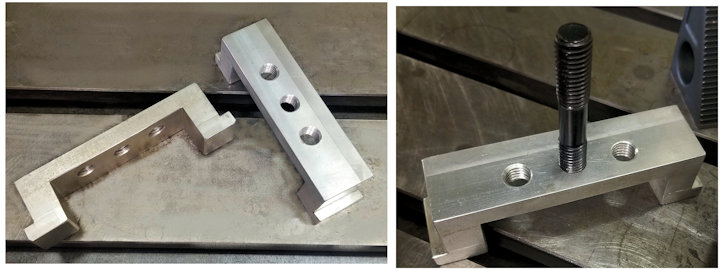

SET UP BLOCKS Keep your tape measure in the toolbox when doing set ups that you repeat time and time again. Make some gauge blocks or fixtures, whatever it takes to save time setting up your machines. Randy Torvinen Torvinen’s Machine Menahga, MN DECEMBER,...

by Donnie Hurt | Dec 1, 2021 | TOOLING

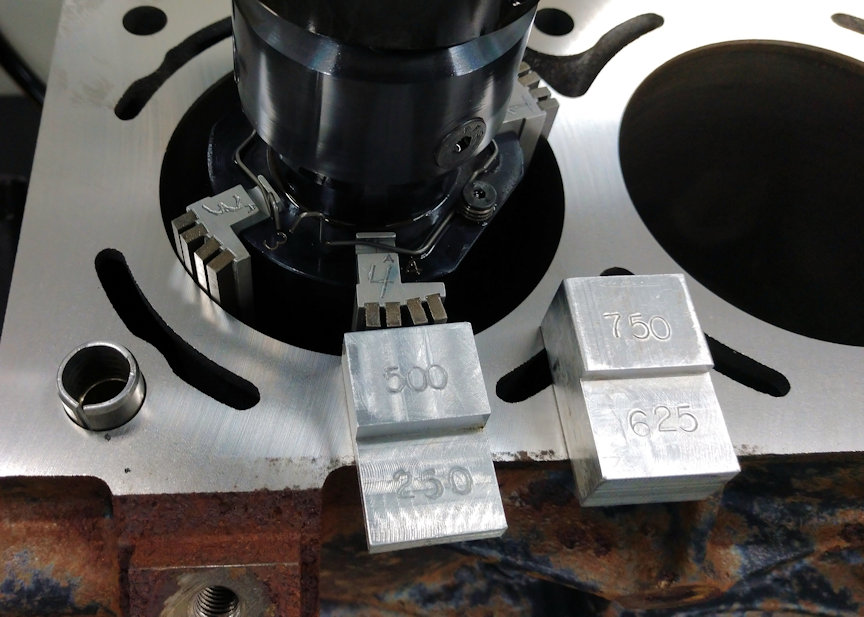

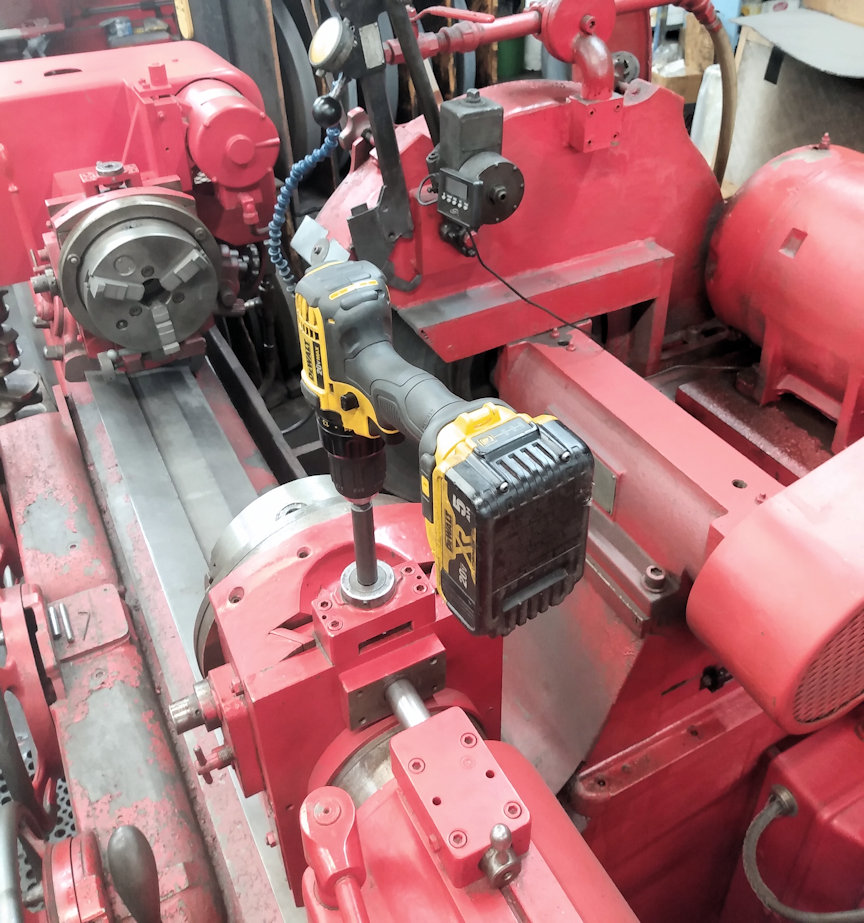

POWER ADJUSTMENTS To save time, we use a half inch cordless drill to power our stroke and counterweight adjustments on our crankshaft grinder machines. Adney Brown Performance Crankshaft Ferndale, MI DECEMBER, 2021

by Donnie Hurt | Dec 1, 2021 | TOOLING

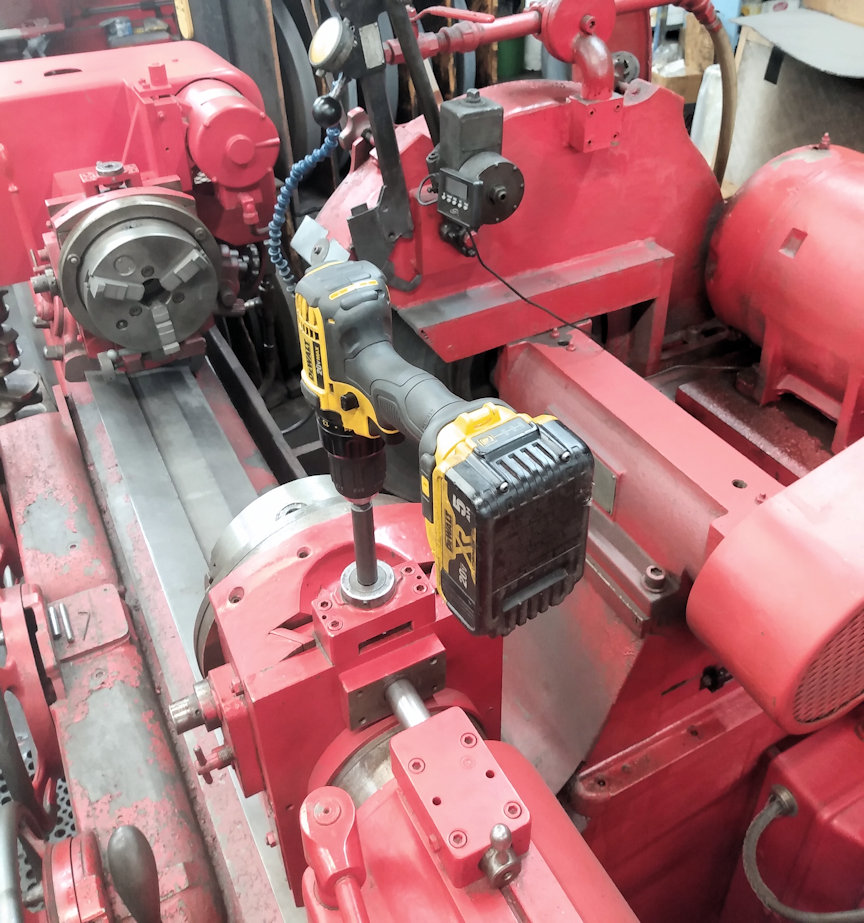

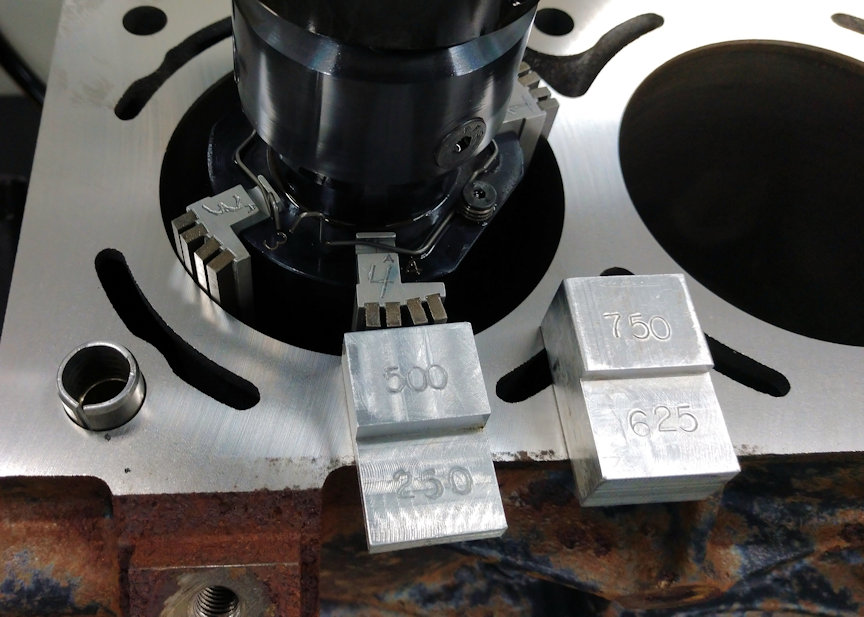

SEAT SPUD For machining custom valve seats, in addition to the expansion arbor, I have a simple aluminum spud and lock. I can quick machine it down for whatever seat I need. It started out as a 1-foot-long piece of round stock, and I just keep drilling and tapping as...

by Donnie Hurt | Dec 1, 2021 | TOOLING

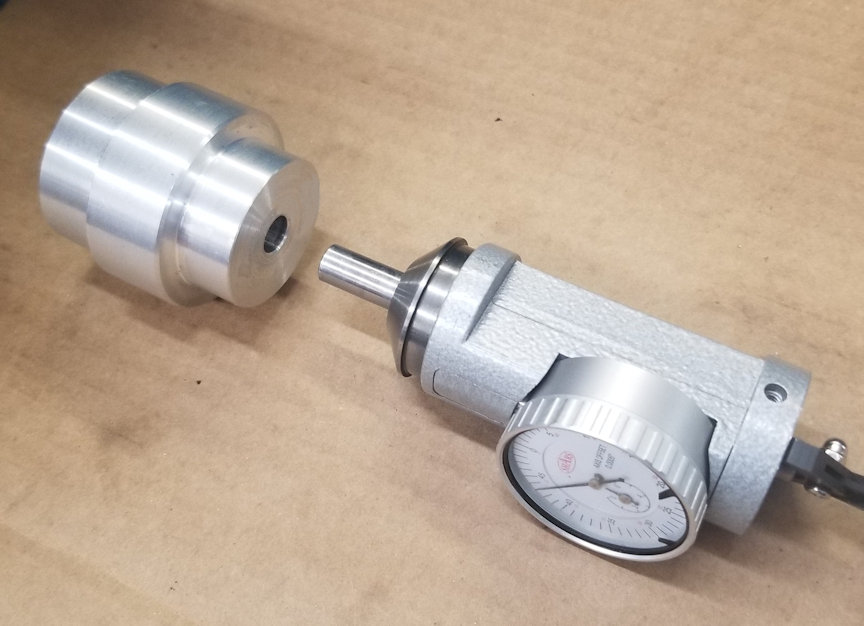

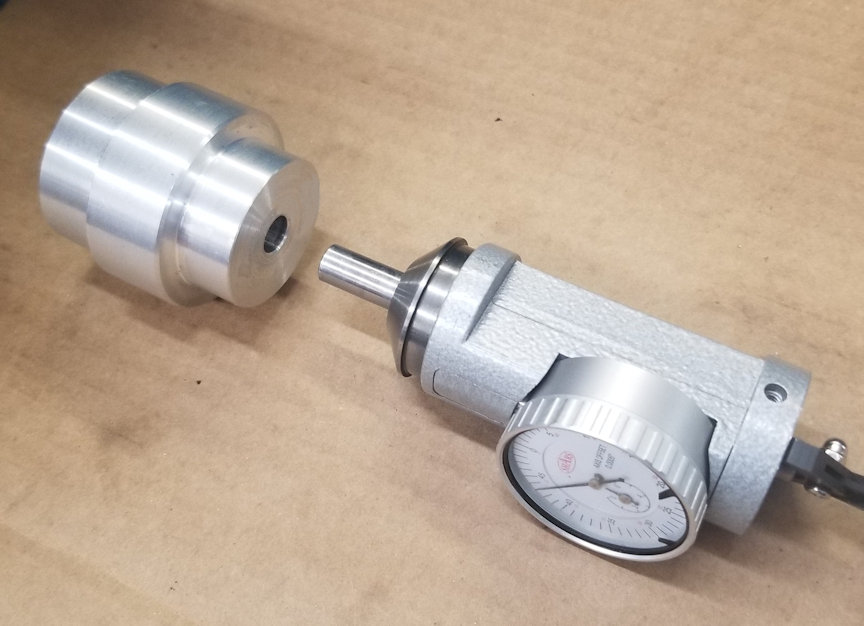

INDICATOR ADAPTER Most Co-Ax indicators have a 3/8″ or 1/2″ diameter stem. Instead of wasting time closing the lathe chuck to hold the indicator and then more time opening it back up to hold a larger diameter work piece, make a simple stepped adapter with...

by Donnie Hurt | Nov 1, 2021 | TOOLING

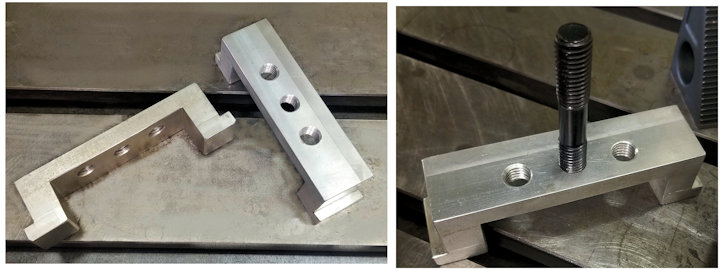

T-SLOT BRIDGE Occasionally, when clamping an odd-shaped part like a cylinder head or small engine block on our Bridgeport mill, the mill table’s T-slots are not always spaced for convenient clamping. To make the job easier and faster, we machined a pair of steel...