by Donnie Hurt | Feb 1, 2021 | PISTONS & RINGS

WHICH WAY IS UP When you are not sure which way the 2nd rings go in or cannot figure out the markings, remember, they are oil scrapers and have a tapered face. I hold one down to see which way it leans vs. a square. The side that leans towards the square is the top...

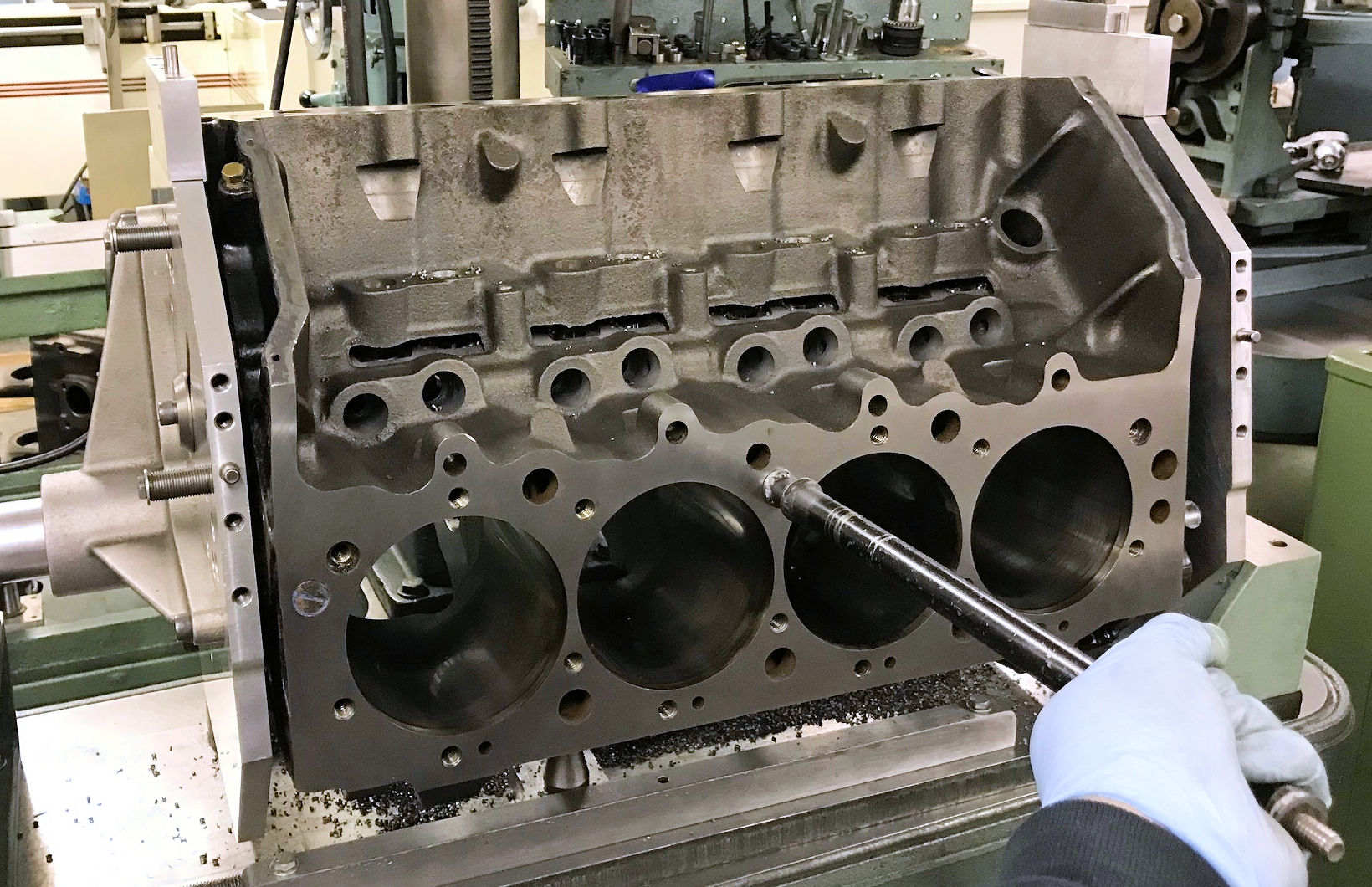

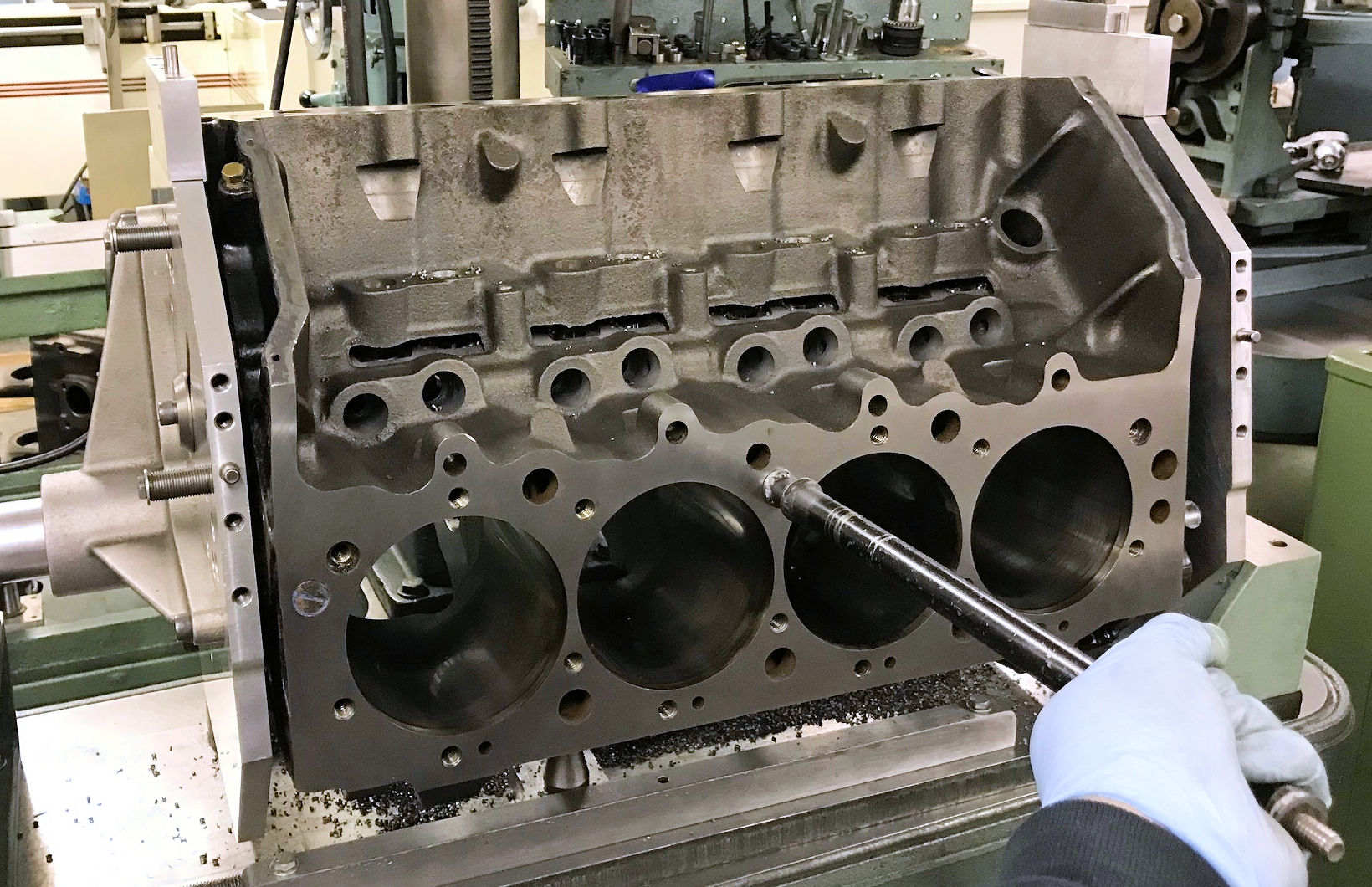

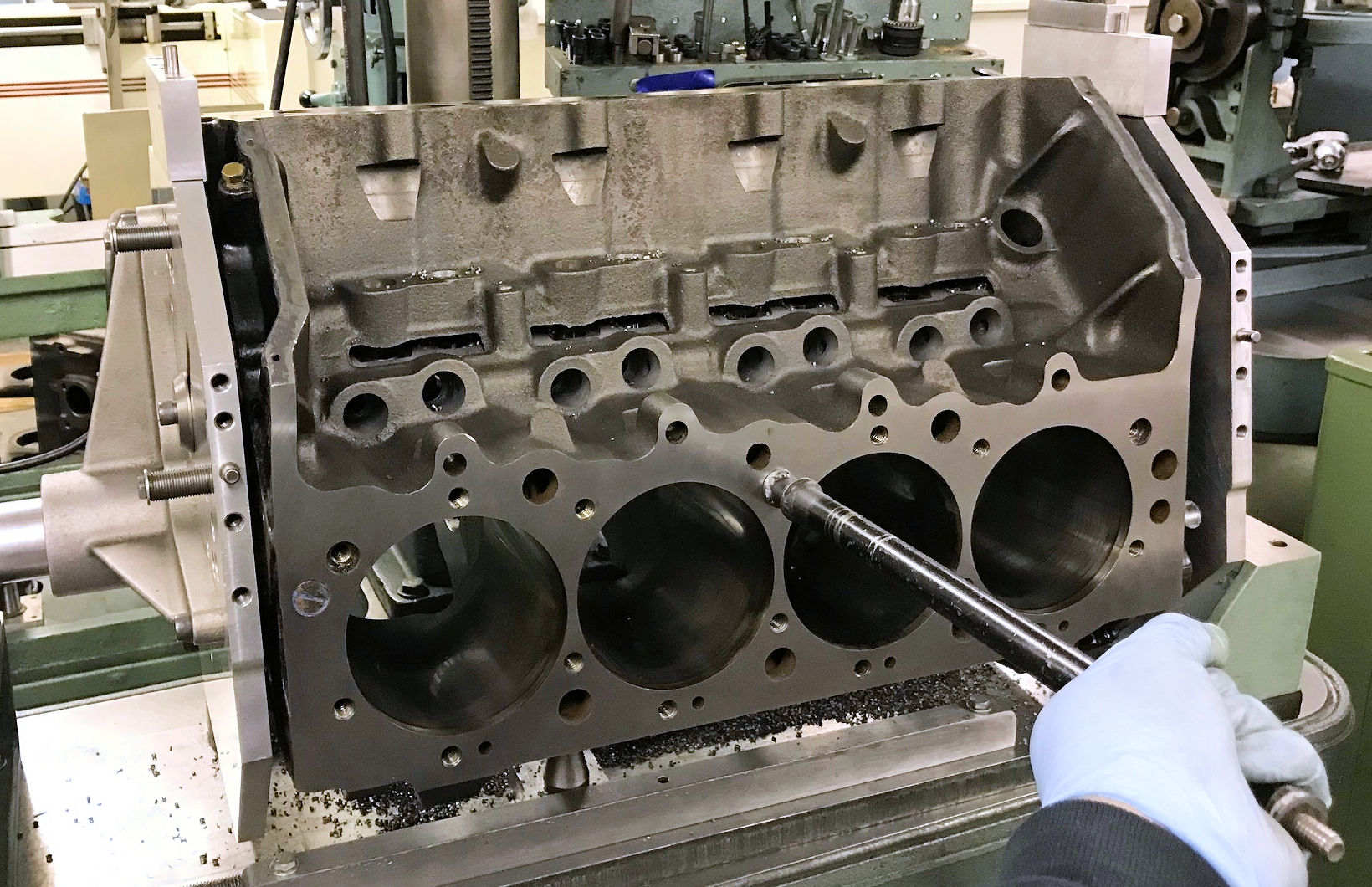

by Donnie Hurt | Feb 1, 2021 | BLOCK WORK

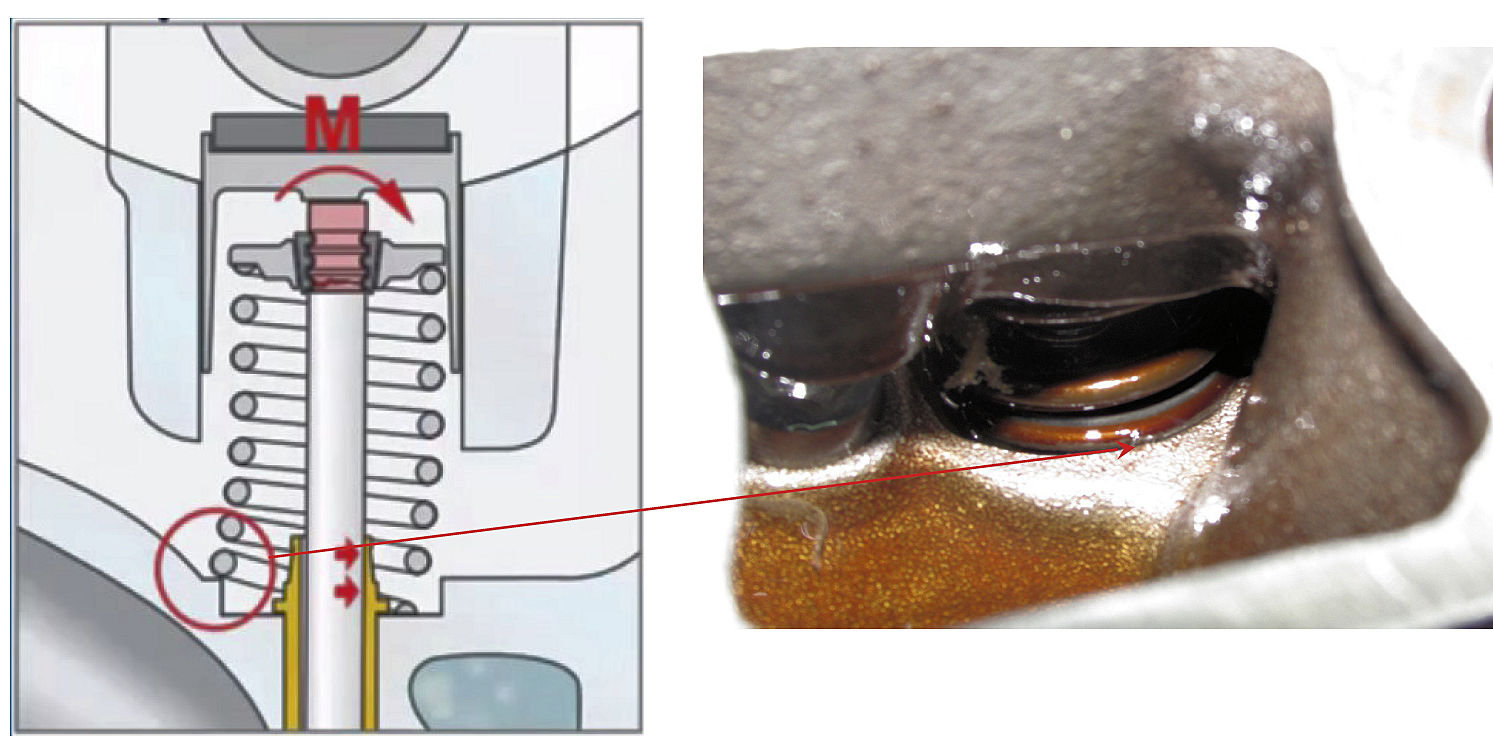

LIFTER BORE GO-NOGO An expedient method of checking and verifying both lifter bore wear and size is with a “go- nogo” gauge. This is not meant to replace the use of a dial bore gauge, just as a quick check. They are easily machined on a lathe. They can be machined...

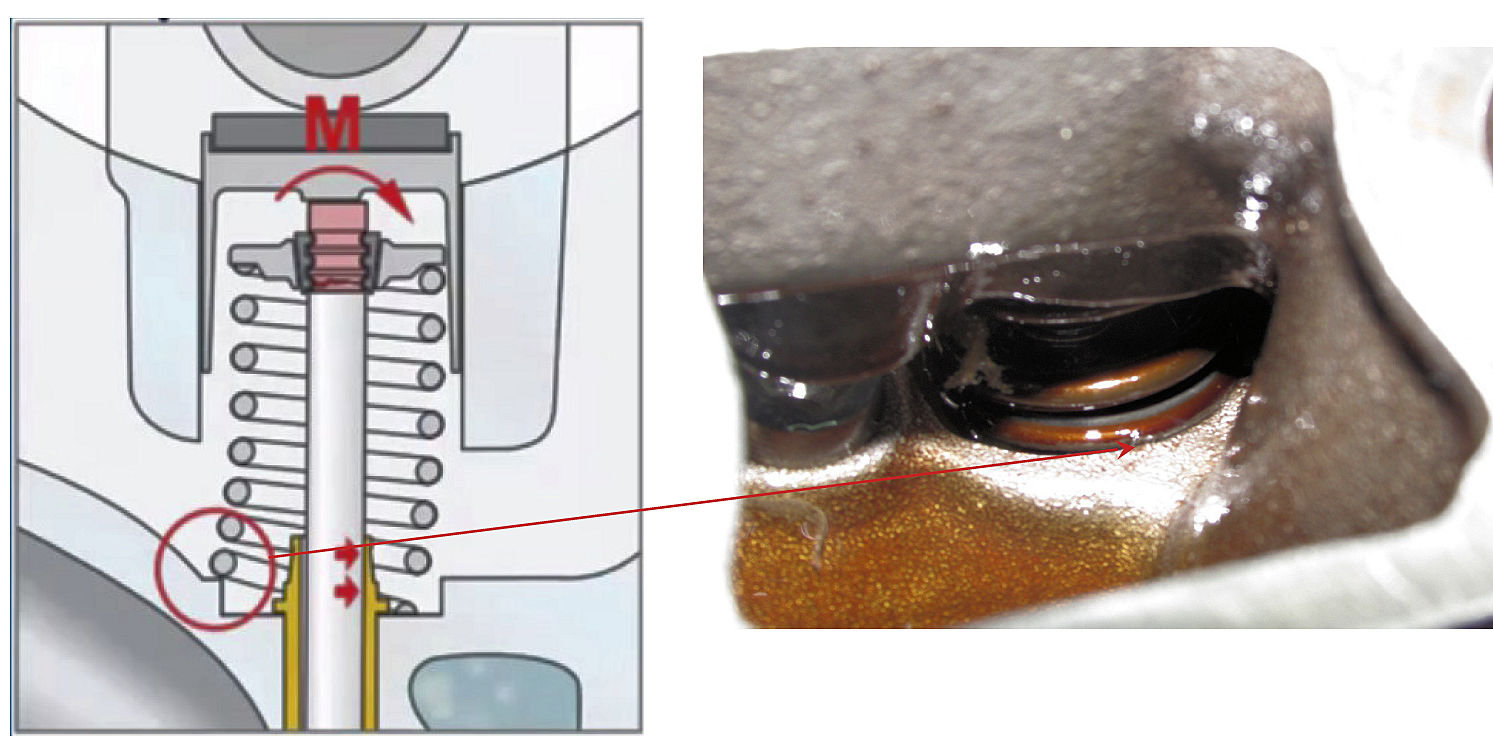

by Donnie Hurt | Feb 1, 2021 | LUBRICATION & COOLING

STOP FRETTING If you work on any high-power adder or high rpm engines, chances are you will see some fretting on the bottoms of main caps and the backside of the upper rod bearing. Even when the tune is right you will still see minor signs of movement between the...

by Donnie Hurt | Feb 1, 2021 | CYLINDER HEADS

VW VALVE BREAKAGE It is not uncommon for the Volkswagen 1.8L, 20-valve cylinder head to require several if not all new intake and exhaust valves once it reaches your shop door. A failed belt, water pump and tensioners can provide quick and devastating havoc inside the...

by Donnie Hurt | Feb 1, 2021 | OTHER SHOP WORK

GOOD TO BE FOILED Keep a roll of kitchen aluminum foil handy in the shop. It is useful for many things including shimming chuck jaws, wrapping parts to keep shavings out, protecting parts from weld splatter, covering mill or lathe ways when machining abrasive cast...