by Donnie Hurt | Jan 1, 2020 | TOOLING

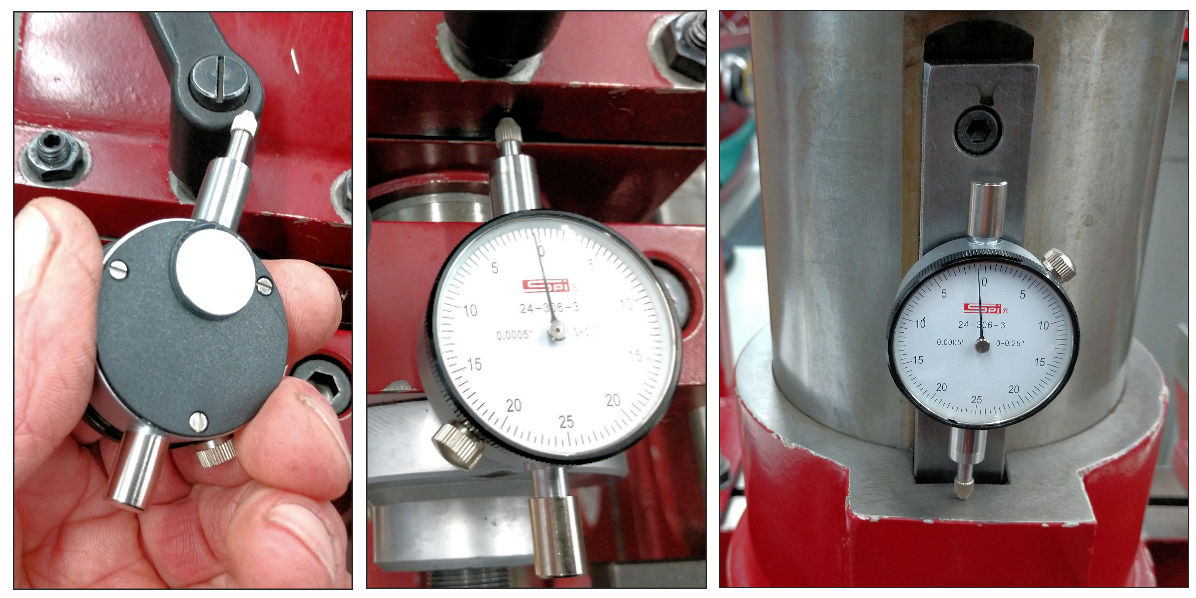

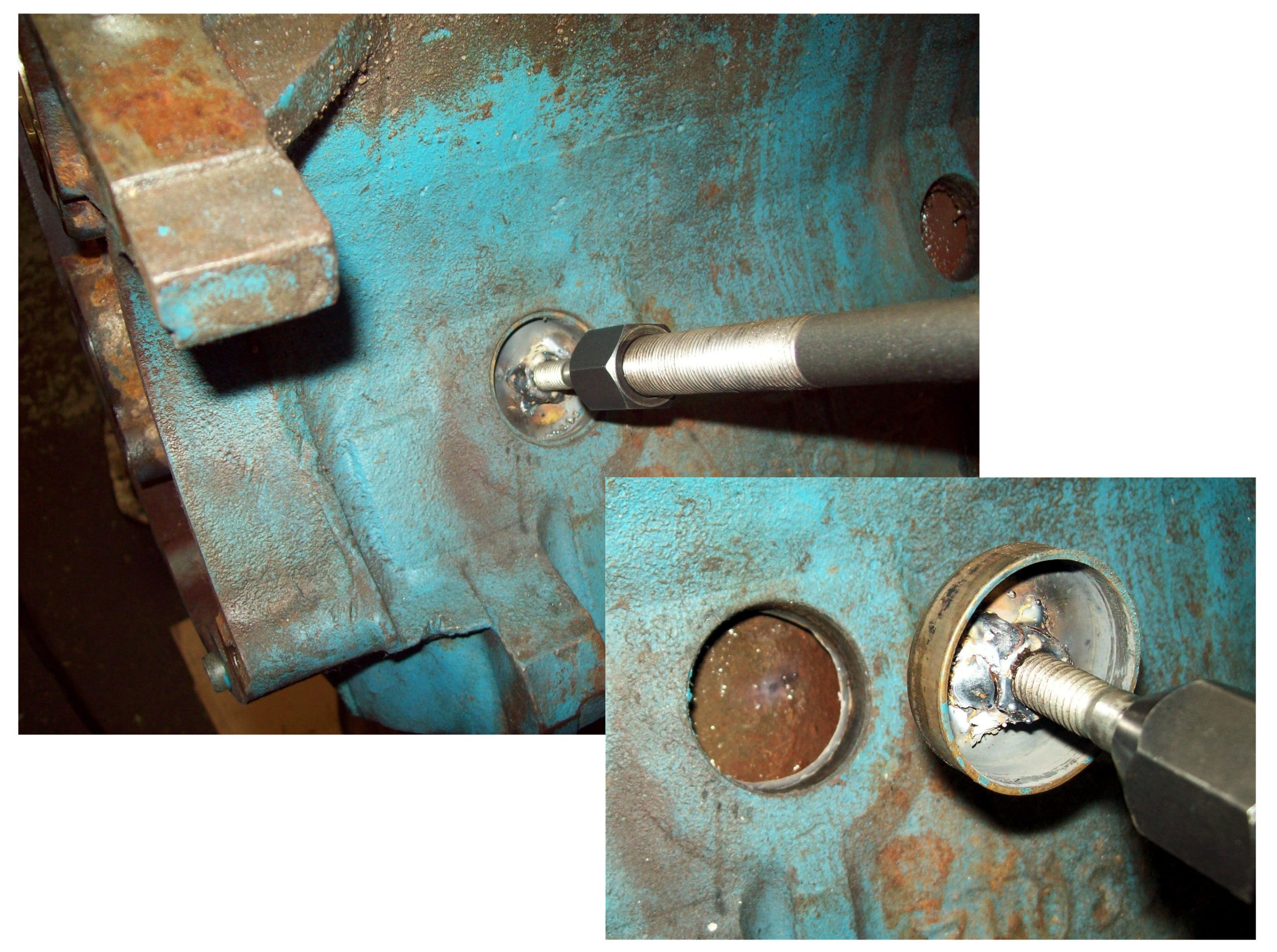

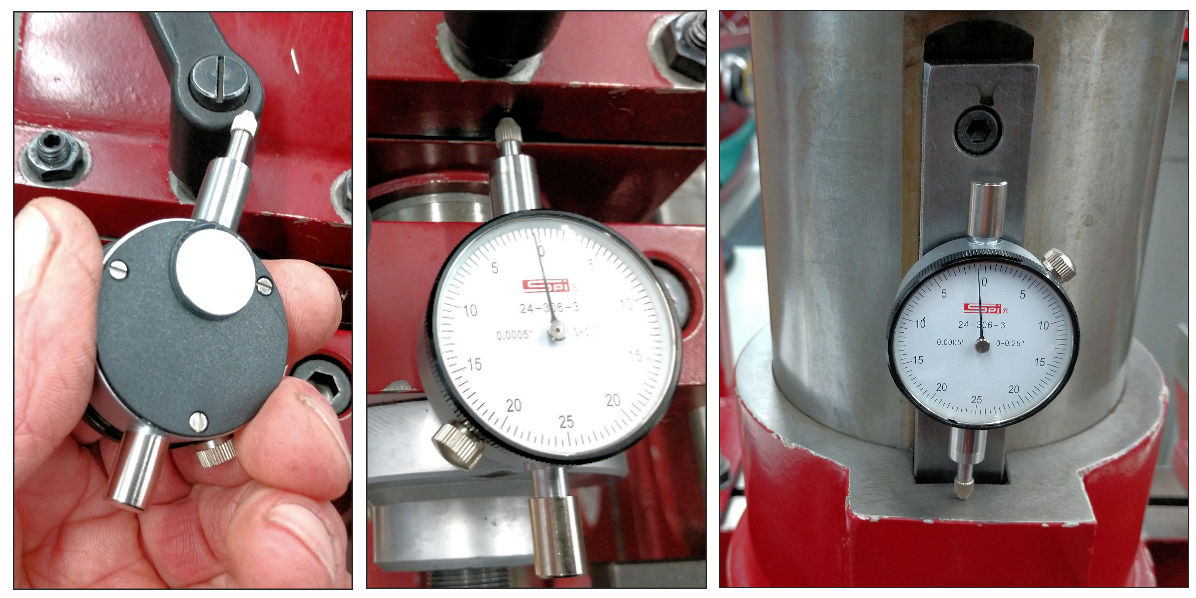

ANYWHERE INDICATOR My Linebore didn’t have any indicators on the column and it’s nice to know the amount you are moving the bar. I just siliconed magnets on the back of these small indicators for easy set-up. I use them on the LineBore and other Machines....

by Donnie Hurt | Dec 1, 2019 | OPERATIONS

RECYCLE YOUR RESOURCES Most piston sets come in a bag. Some customers do not take off all the external parts when they bring in cylinder heads. Use those piston bags to put the various cylinder head parts in to keep them organized for reassembly. Place a label on...

by Donnie Hurt | Dec 1, 2019 | DISASSEMBLY & CLEANING

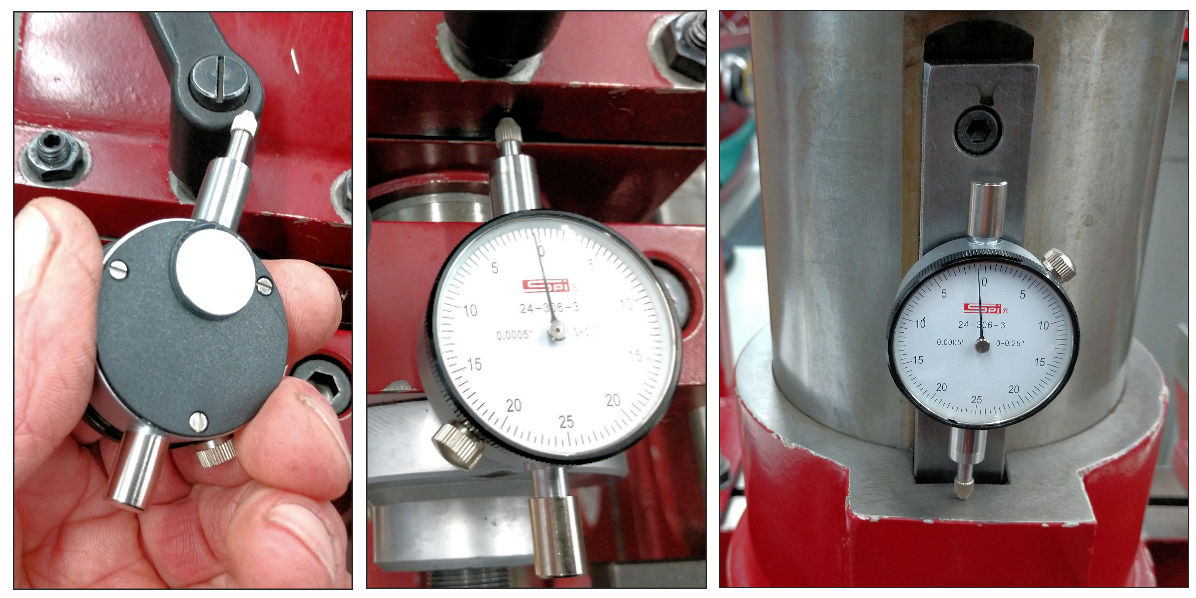

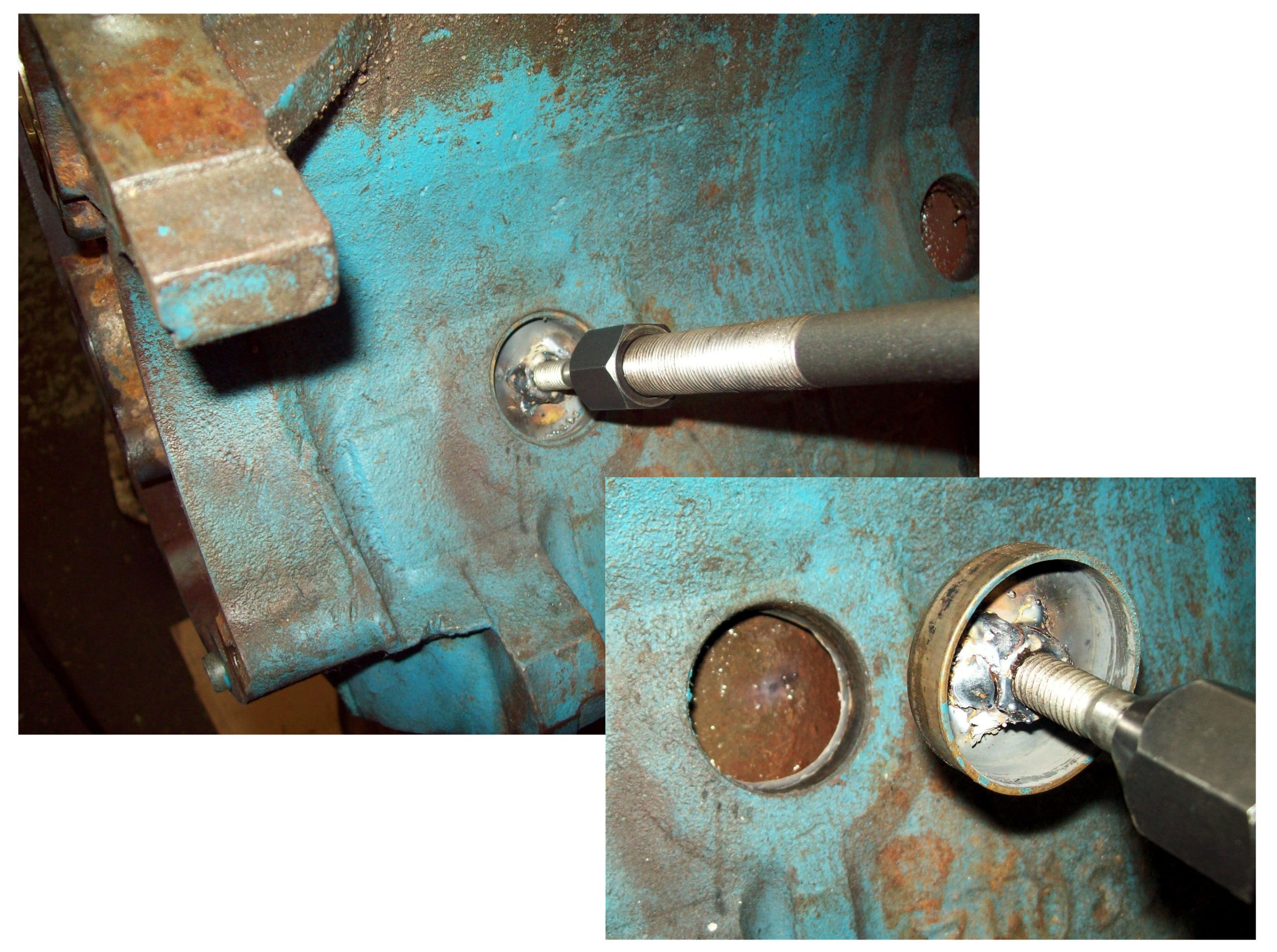

CORE PLUG PULLING Some core plugs are notoriously tricky to remove. One example, that I see a lot of, is the deep plugs used in the back two positions of big block Chryslers where the cylinder wall is close to the plug hole. I simply tack weld a nut to the core plug....

by Donnie Hurt | Dec 1, 2019 | DISASSEMBLY & CLEANING

SIMPLE SCRAPER I made a few of these simple scrapers to leave around the shop. They’re really great for getting after rusty surfaces. An aluminum handle with used carbide tooling bolted on. They are simple to make. Repurpose your bits! Randy Torvinen...

by Donnie Hurt | Dec 1, 2019 | CYLINDER HEADS

WORKING SMARTER We have used a Lisle hand held keeper installer tool to assemble small import heads for many years. It can be hard on your hand pushing on the tool to get the keepers to seat, especially on aftermarket springs that are stiffer than the originals. But...