by Donnie Hurt | Sep 1, 2019 | BLOCK WORK

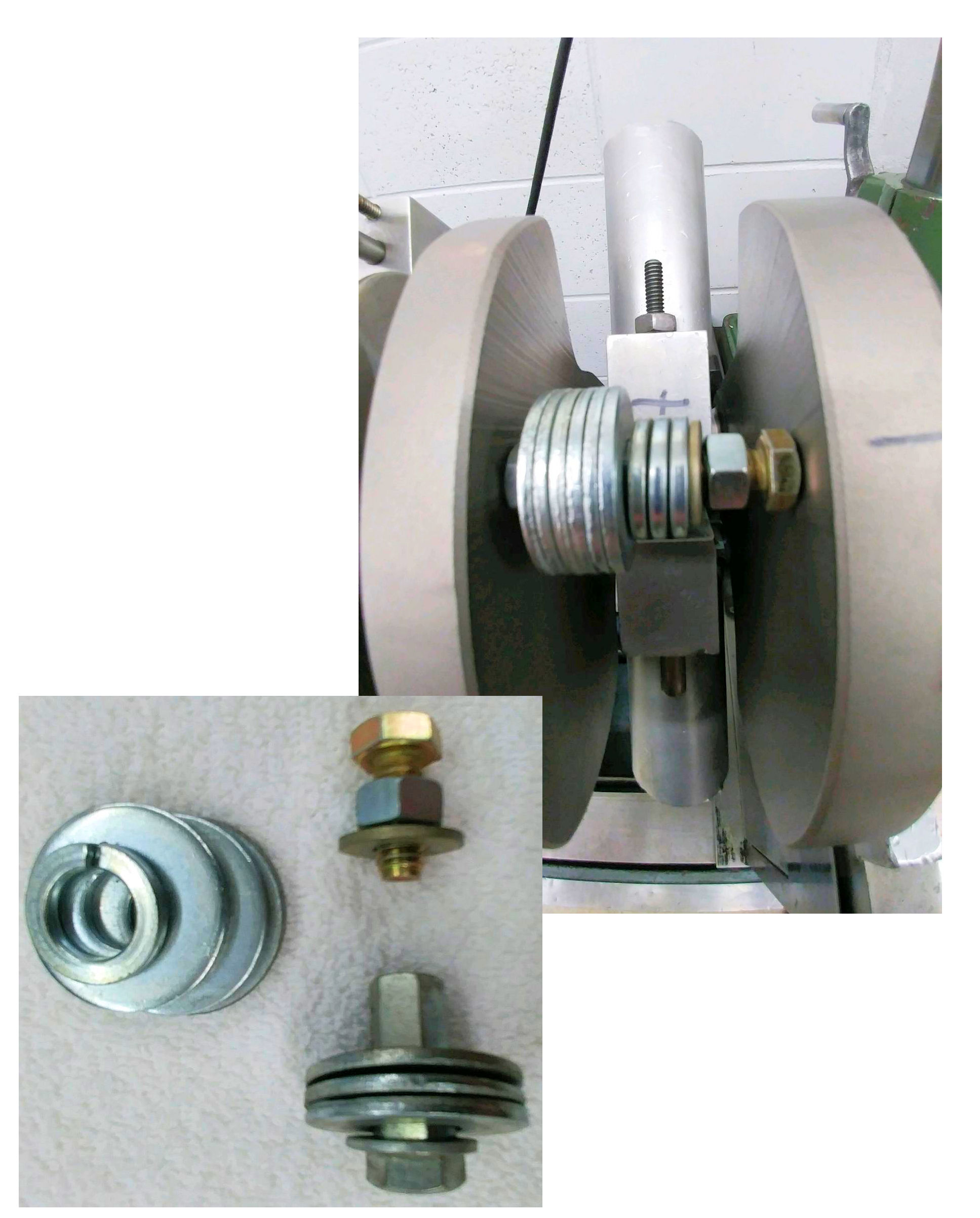

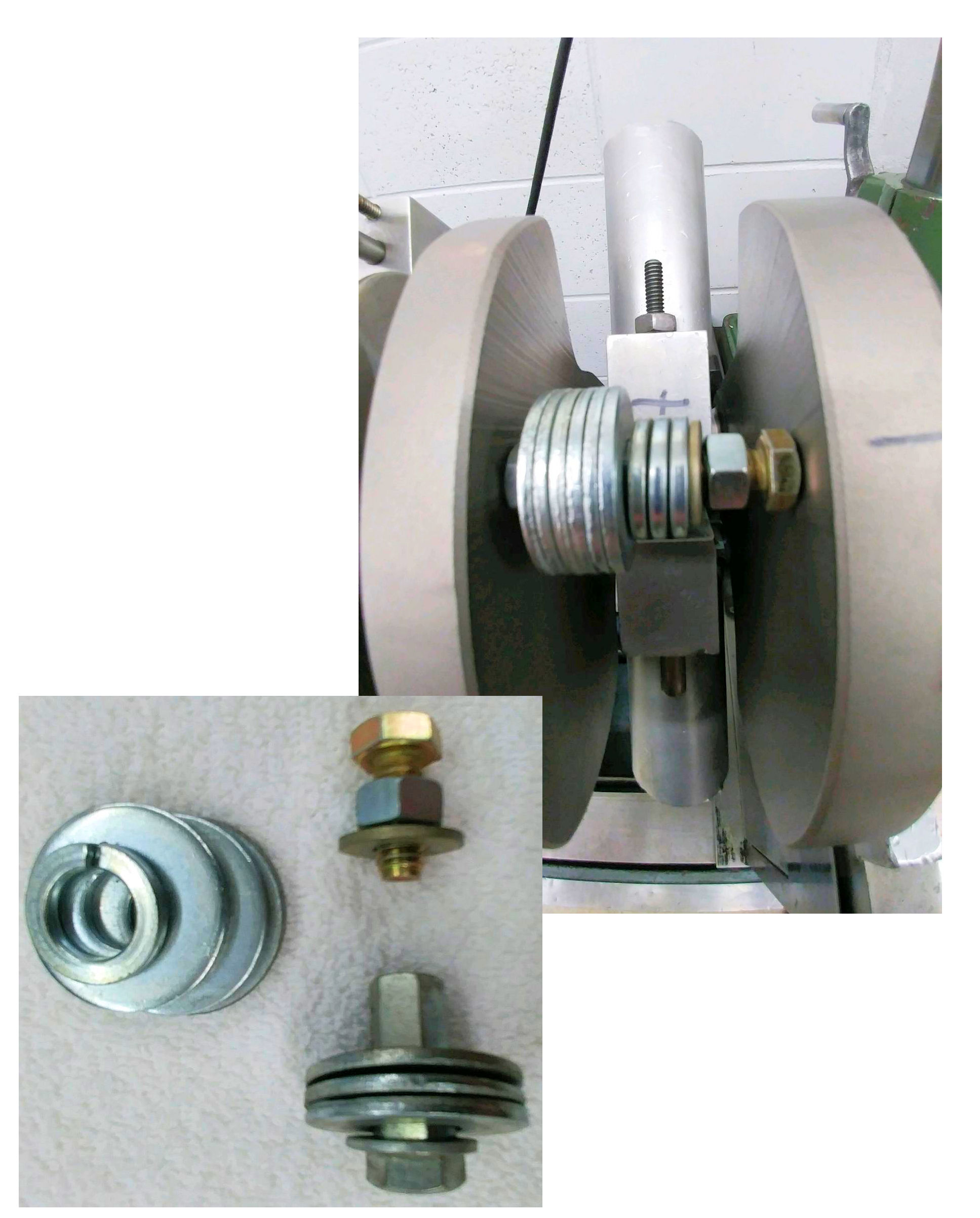

SUBARU CASE CLAMP The Subaru opposed 4-cylinder has a split case or block. I came up with this solution to hold down Subaru blocks so we can surface them. It works real well and holds the block firmly in place. Its a metal bar cut to fit inside of the cylinder. I...

by Donnie Hurt | Sep 1, 2019 | OPERATIONS

IS YOUR SHOP HYPERLOCAL? How does a new potential customer find your shop? Yellow Pages are out… smartphones are in! Have you had occasion to type, or better yet, use voice commands with your smartphone to find a restaurant “near me”? This...

by Donnie Hurt | Sep 1, 2019 | PISTONS & RINGS

RING INSTALL PLATFORM When I opened my shop, I used to struggle with holding pistons between my knees while installing rings. One day I noticed that on the common shop cart, most piston and rod assemblies would fit perfectly between the handle and the cart. It holds...

by Donnie Hurt | Sep 1, 2019 | CRANKSHAFTS & CONNECTING RODS

BALANCING ACT When adding heavy metal to a crank while balancing, the correct placement can be determined by adding the effective gain of your tungsten slug by moving this adjustable device to the approximate location on the counterweight and dialing in the exact...

by Donnie Hurt | Aug 1, 2019 | OPERATIONS

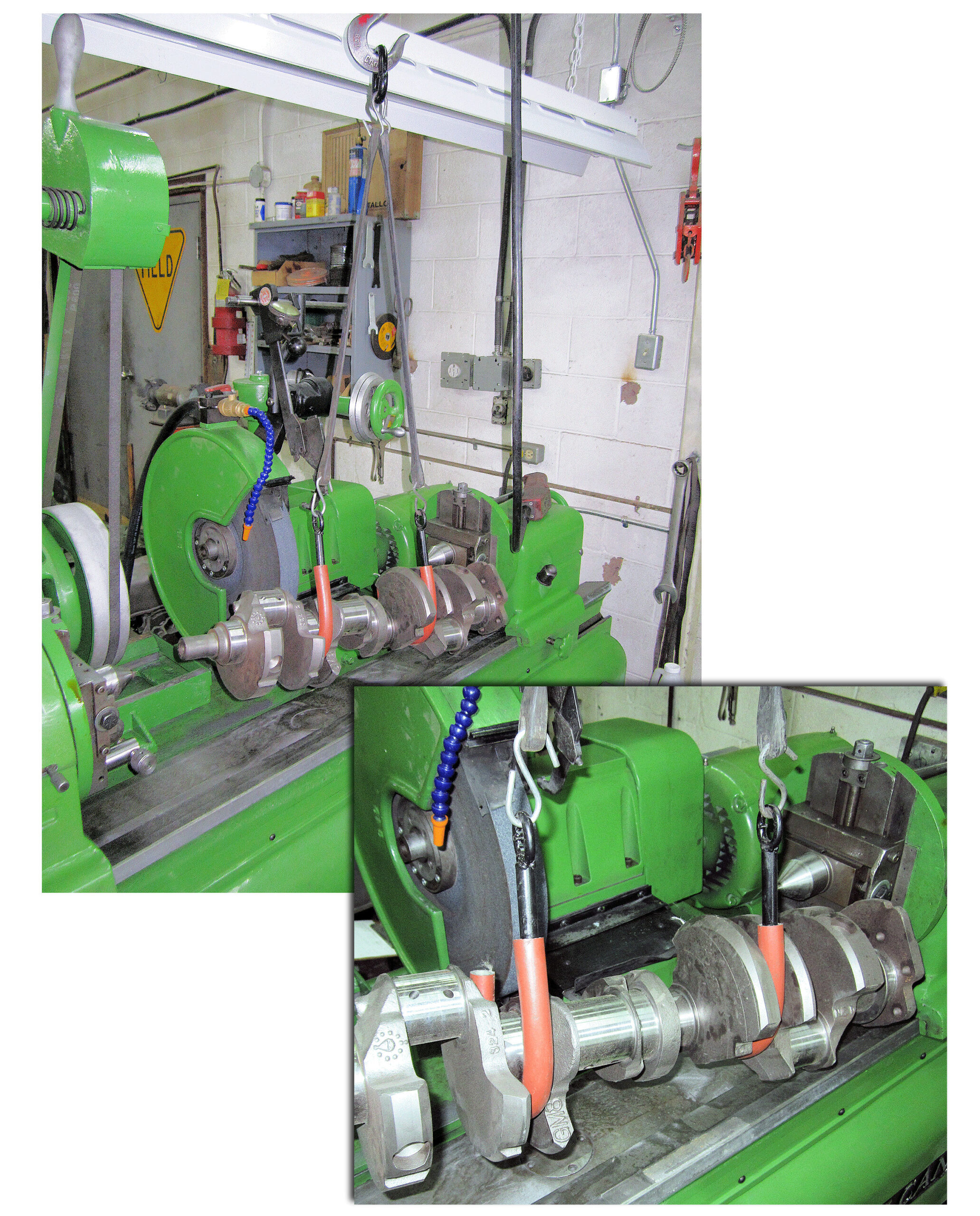

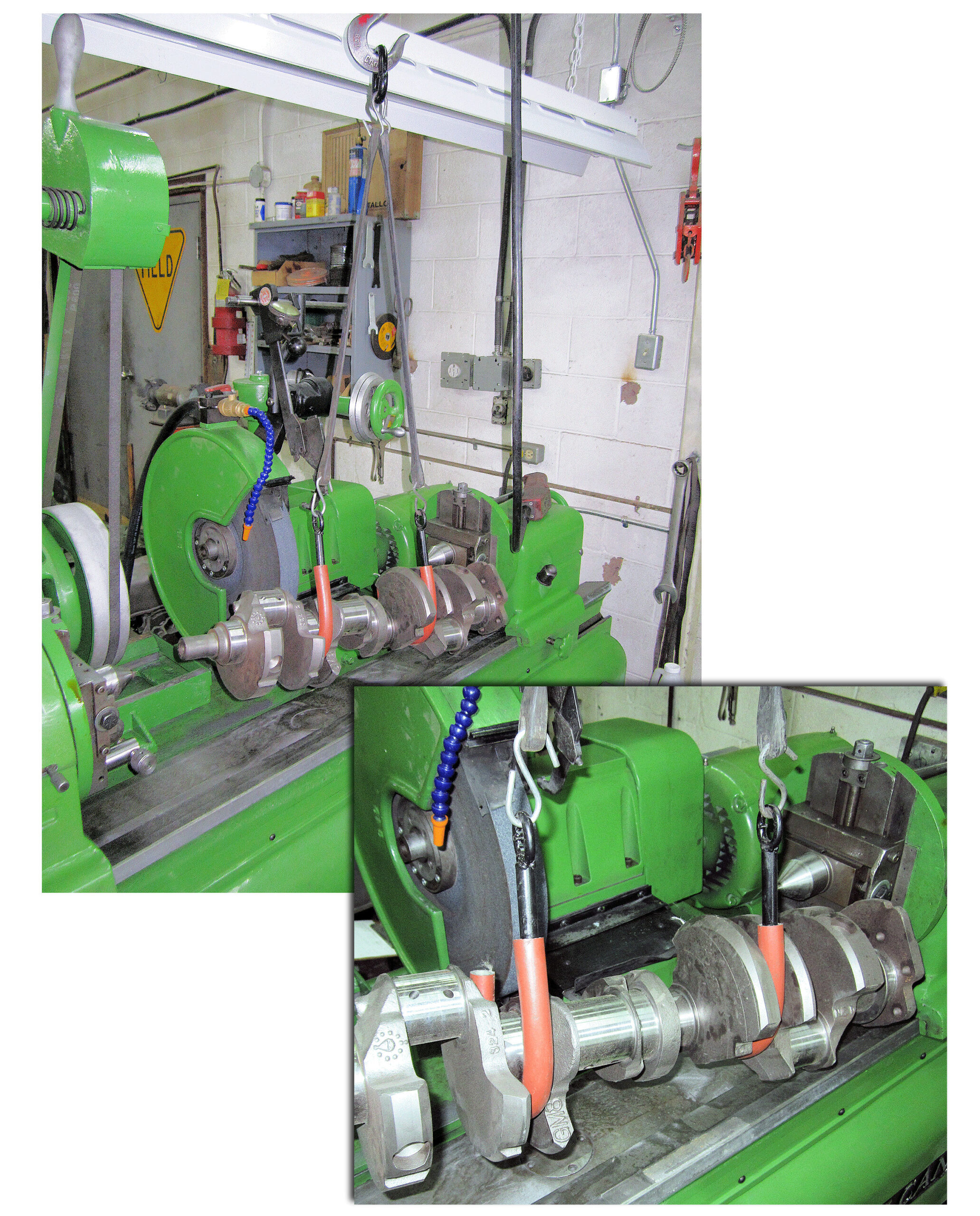

SLING YOUR SHAFT I have muscled crankshafts into place and used various methods of “slinging” them. I found this sling to be simple and easy. I built the hooks out of 1/2” steel rod and slid some heater hose over them to protect the crank’s bearing surfaces. I...