BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

QUICK CHANGE HOLDER

Jun 1, 2015 | TOOLING

QUICK CHANGE HOLDER Many of our company’s jobs are short runs, with setups that needed to be changed sometimes every two to four hours. Work holding setup time was something that became necessary to improve as our volume of work increased. By investing in a...

Measuring Concave Objects

Jun 1, 2015 | TOOLING

Measuring Concave Objects If you need to measure a concave object such as a lifter or push rod and don’t have a ball mike, or don’t have one large enough, you can use a bearing ball in the concave part and subtract the diameter of the ball from the overall...

RUBBER BANDS TO THE RESCUE

Jun 1, 2015 | CYLINDER HEADS

Rubber Bands to the Rescue Don’t have enough hands to drop a cam shaft rocker assembly on a VTech and other overhead cam motors? Try using rubber bands to hold the rocker arms together on the shaft assembly to help prevent the shifting of the rocker arms and the pivot...

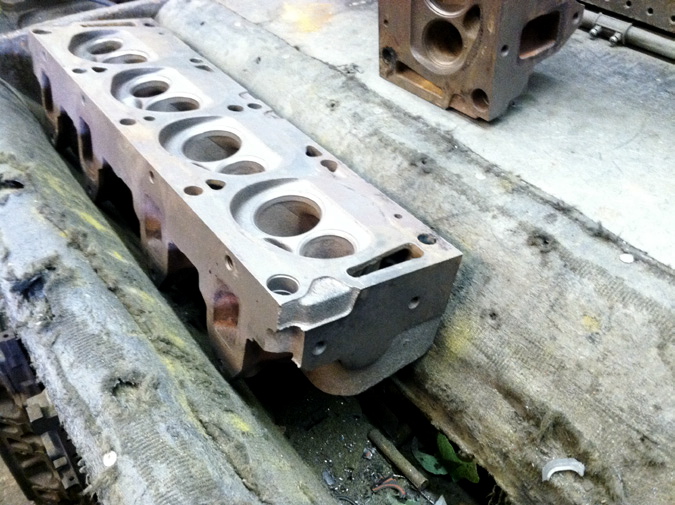

OLD SCHOOL HEAD BENCH

May 1, 2015 | CYLINDER HEADS

OLD SCHOOL HEAD BENCH This is very basic and has been in our shop for over 30 years. It’s been rebuilt twice, which means new carpet was installed on the V-blocks. The weight of the head, or gravity and the carpet on the V-blocks works to hold the head snugly in...

MOCK LIFTERS

May 1, 2015 | CAMSHAFTS & VALVE TRAIN

MOCK LIFTERS For hydraulic lifter applications, I speed up the process for checking pushrod length, pre- load and geometry by using “solid” lifters. I disassemble a lifter and load it up with either epoxy or Plaster of Paris to position the plunger in a permanent...

DIESEL HEAD STUD RETORQUE

May 1, 2015 | ASSEMBLY

DIESEL HEAD STUD RETORQUE In our shop we do a variety of cylinder heads for late model diesel trucks. On jobs like 6.0 Fords, 5.9 Cummins, or 6.6 Dura- max our customers often install ARP studs as in improved fastener. ARP highly suggests that the studs be retorqued...