BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

SURFACING QUICK CHANGE

Dec 1, 2023 | CYLINDER HEADS

SURFACING QUICK CHANGE I have made a quick-change for going between surfacing aluminum and cast iron heads. For aluminum heads I use a PCD plate and 750 tr/min on an arm with 2-strong bolts with guiding in a stone head. For steel I use grinding stones and 1800tr/min...

CLEANING 3-JAW CHUCKS

Dec 1, 2023 | TOOLING

CLEANING 3-JAW CHUCKS This is a quick & easy way to clean 3-jaw crankshaft grinder and lathe chuck scrolls. - Make a stubby chuck key driver for use in a cordless drill; quickly remove the jaws. - Insert a toothbrush in one of the jaw slots, then run the...

LIFTING HEAVY CRANKSHAFTS SAFELY

Nov 1, 2023 | DISASSEMBLY & CLEANING

LIFTING HEAVY CRANKSHAFTS SAFELY We found placing cranks, whether light or heavy, can be difficult to do on a hot tank pressure washing stand. And this is even harder to lift after the crank is washed and hot. To protect the machined surfaces and make it safer, pick...

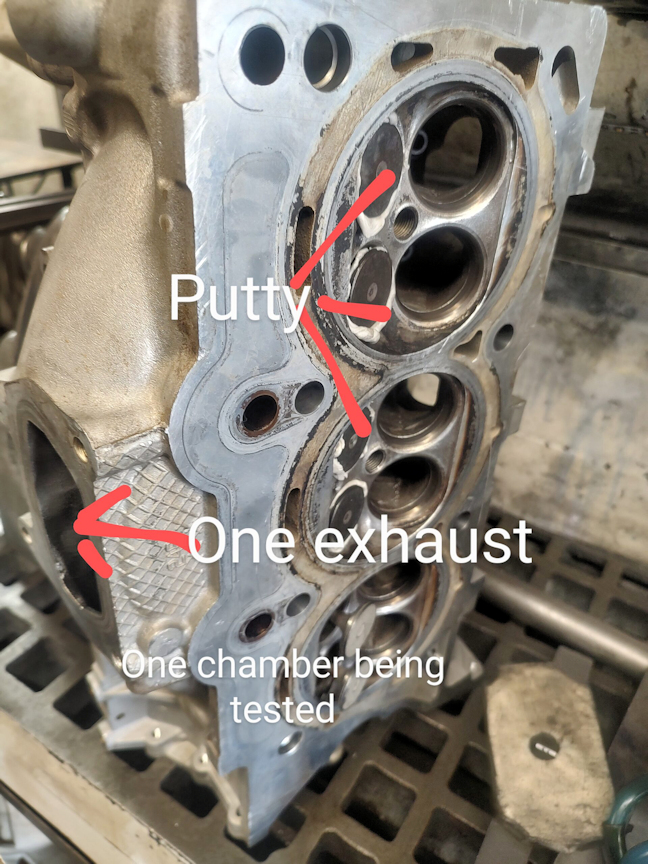

SINGLE EXHAUST VACUUM CHECKING

Nov 1, 2023 | CYLINDER HEADS

SINGLE EXHAUST VACUUM CHECKING If you are like me, you test all the valve to seats seal with a vacuum test. It’s not possible when you have a single exhaust system. What I use is plumbers’ putty on the valves of the chambers not being tested to assure a good seal. It...

OIL BOTTLE

Nov 1, 2023 | TOOLING

OIL BOTTLE We modify small plastic bottles, purchased on-line, for cutting oil, tapping fluid, assembly lube, etc. We've tried bottles with dispenser tips, however those with metal "needle tips" can scratch parts, while the plastic tips are usually too short, or...

NARROWING BEARINGS

Nov 1, 2023 | CRANKSHAFTS & CONNECTING RODS

NARROWING BEARINGS When I need to narrow a set of rod bearings, I have bucks that I’ve turned to the size of the crank pin. Then, I wrap a single layer of masking tape around them to protect the bearing. I hold the bearing to the spud with a couple hose clamps,...