BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

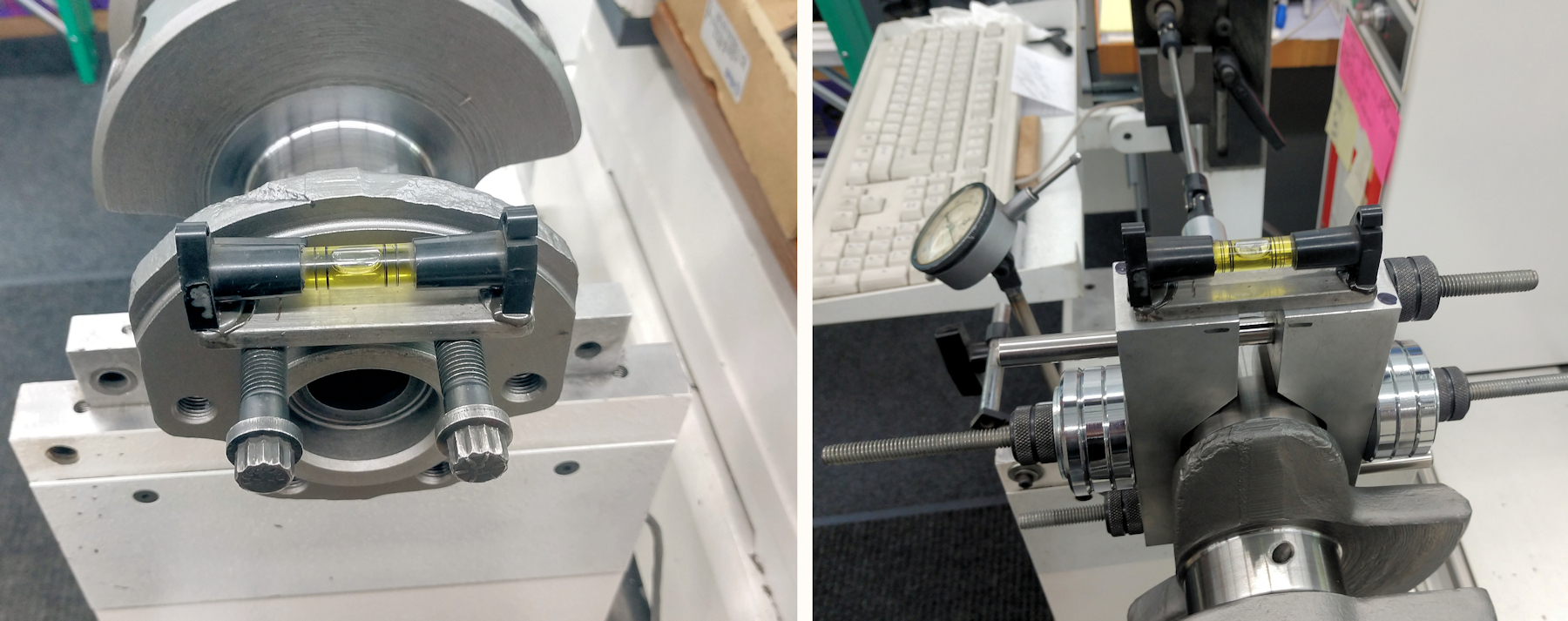

BOBWEIGHT PLACEMENT

Aug 1, 2021 | CRANKSHAFTS & CONNECTING RODS

BOBWEIGHT PLACEMENT I always “phase” my bobweights. I start by screwing in a couple bolts into the crankshaft flange. It seems to be a good starting place and seems to place the first throw up. I level across the bolts then 0 my degree wheel. Then I level each...

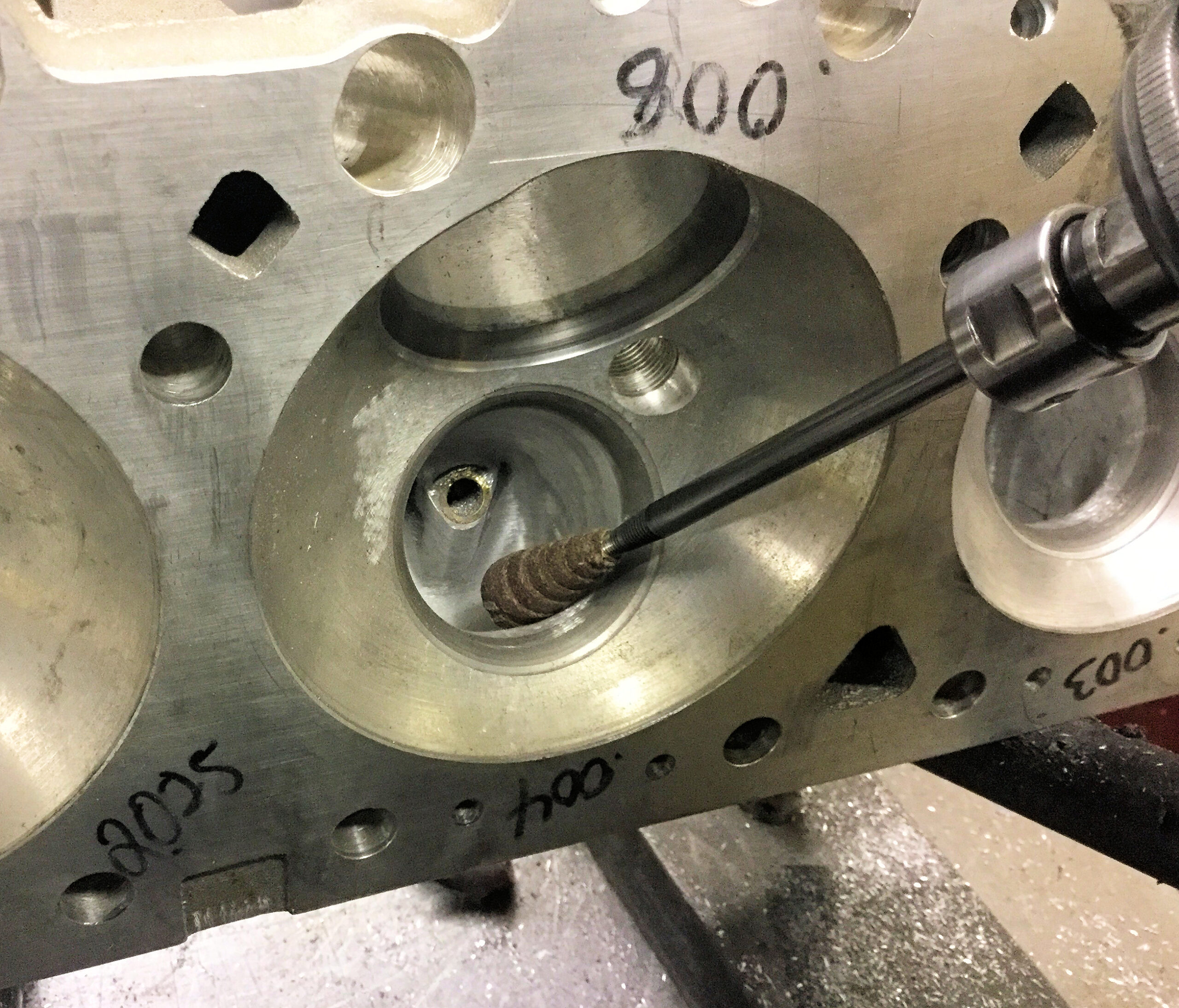

CYLINDER HEAD PORTING TIP

Aug 1, 2021 | CYLINDER HEADS

CYLINDER HEAD PORTING TIP When doing port work and rolling the short turn radius, sometimes it’s difficult to get in there and get a good angle with the burr or sanding roll. I use a tapered cone type cartridge roll, but I flip it backwards on the mandrel. This will...

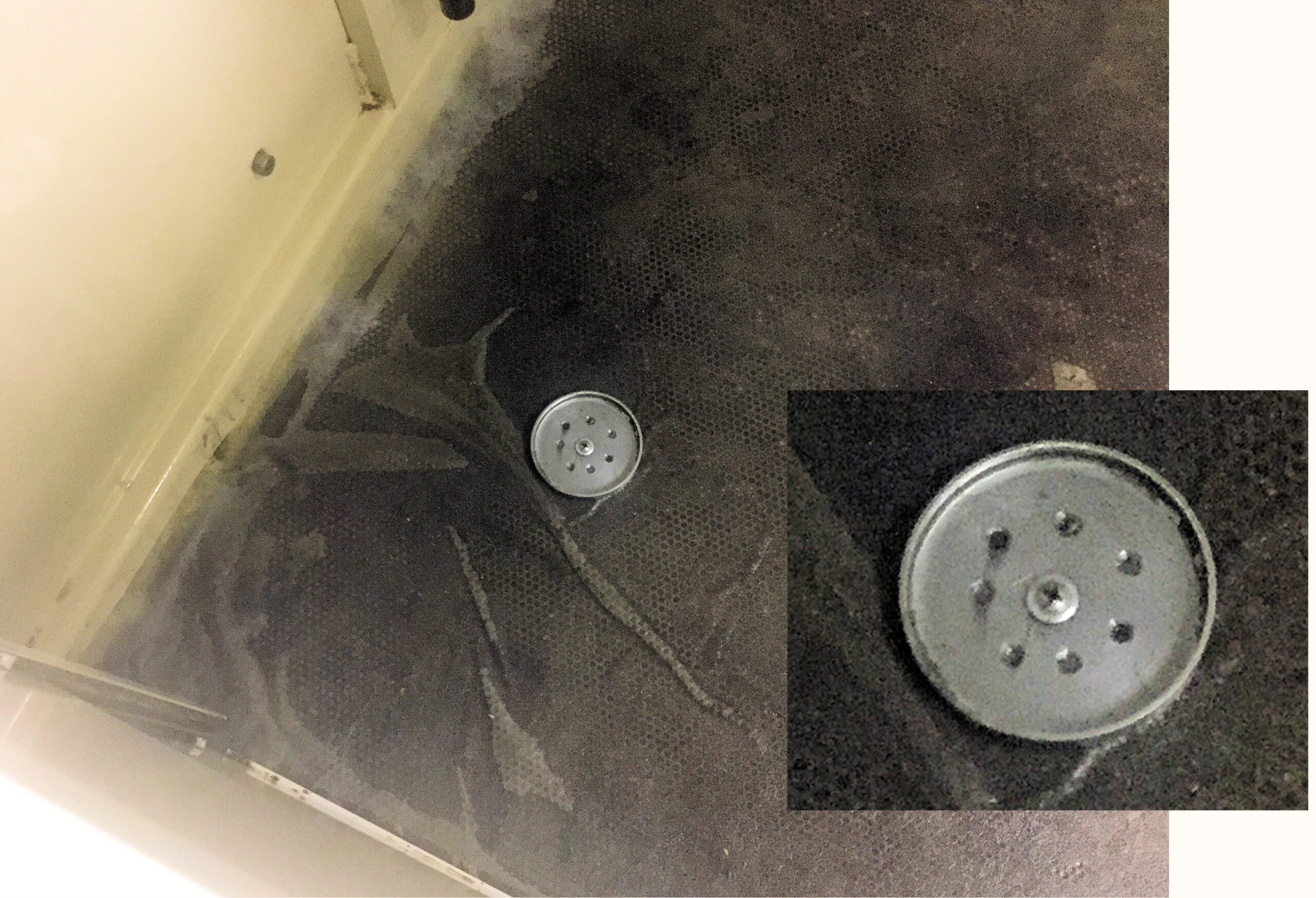

KEEP IT CLEAN

Jul 1, 2021 | TOOLING

KEEP IT CLEAN On the line honing machine, the mandrel rest and tank sides can end up becoming a real mess, especially after the job while the mandrel drains off. I took a large cup freeze plug and drilled some drain holes in it. I screwed this to the metal screen...

SHIM IT

Jul 1, 2021 | CRANKSHAFTS & CONNECTING RODS

SHIM IT We shim many different components to get square or level before we machine. Don't forget the rod and cap when cutting for resizing. Shim to get the parting surface to cut as the factory did whether it's 90 degrees to the sides or not, and your rods will turn...

DAS ARNOLD GAUGE

Jul 1, 2021 | TOOLING

DAS ARNOLD GAUGE It is a common thing with Arnold Gauge calipers to have the original set screws strip out. Many try welding the holes shut or drilling a new hole. We have found that by simply re-tapping the hole for a 3mm set screw it will make it like new. Adney...

MODIFIED VALVE SPRING COMPRESSORS

Jul 1, 2021 | TOOLING

MODIFIED VALVE SPRING COMPRESSORS About twenty years ago cam lifts and valve spring pressures were on the increase. Today, 1000 lbs open pressure is not unheard of. This increases taxation of many existing valve spring compressors and their tooling. Shown are some of...