BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

HEX HEAD VALVE NUT

Apr 1, 2021 | DISASSEMBLY & CLEANING

HEX HEAD VALVE NUT Disassembling an old stuck engine can be challenging. When valves are stuck in the valve guides, try welding a nut to the face of the valve. Now you can rotate it to help free it from the guide. Dave Matton D and D Auto Machine Bloomington, MN...

SUPPORT RAIL INSTALL

Apr 1, 2021 | PISTONS & RINGS

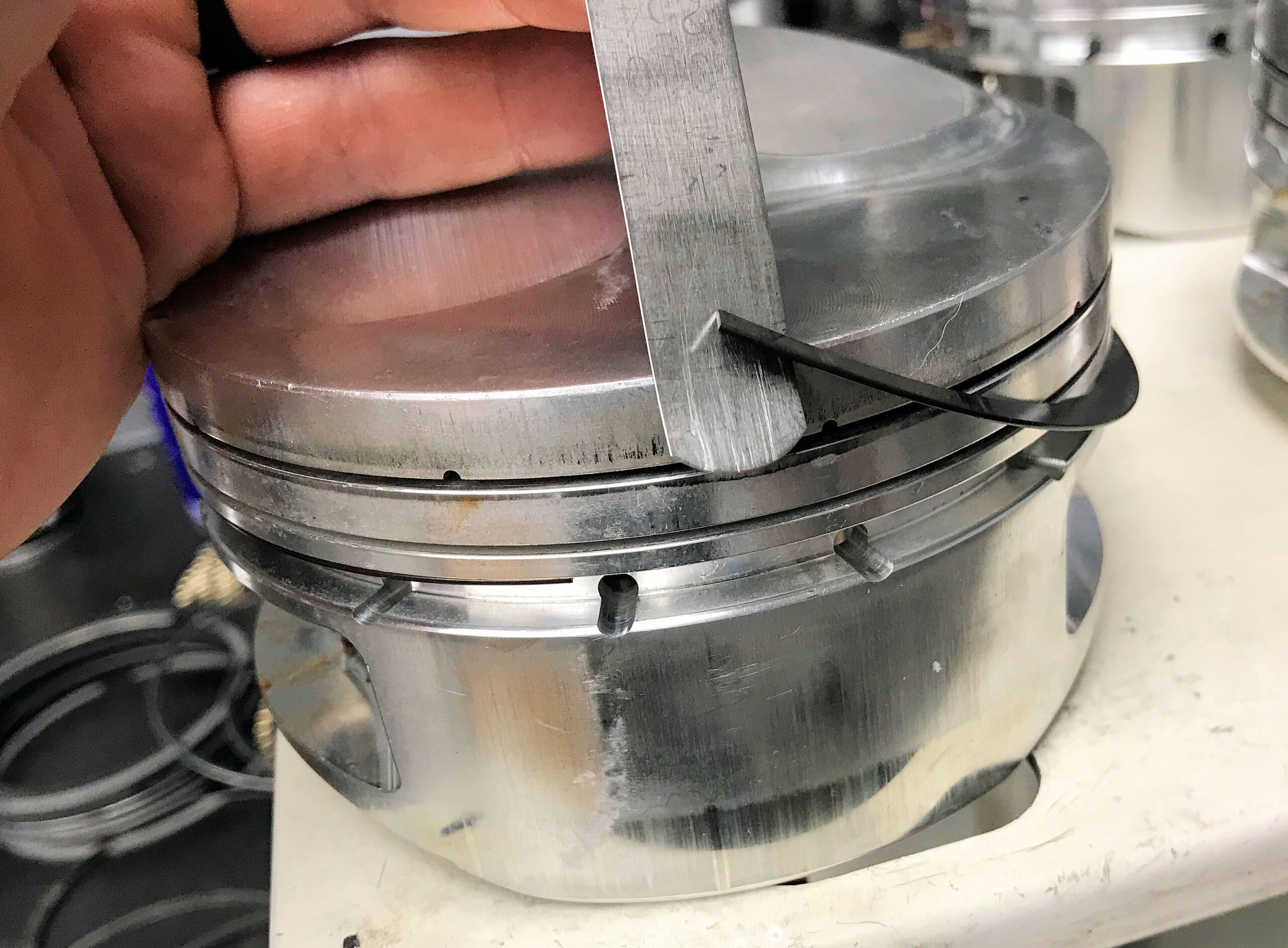

SUPPORT RAIL INSTALL When using pistons that require oil ring support rails, we use a .008” feeler gauge between the piston and the rail as we slide the rail into place. This way it does not scratch the piston or catch as its going into place. Adam Cofer Salina Engine...

CRANK BALANCE SOCKET

Mar 1, 2021 | CRANKSHAFTS & CONNECTING RODS

CRANK BALANCE SOCKET If your shop has a particular crankshaft design you tend to balance on a regular basis, we recommend using a crankshaft snout socket as a locator on your magnetic attachment for rpm and position on your balancer. This allows you to quickly remove...

ANTI-VIBRATION TOWEL

Mar 1, 2021 | OTHER SHOP WORK

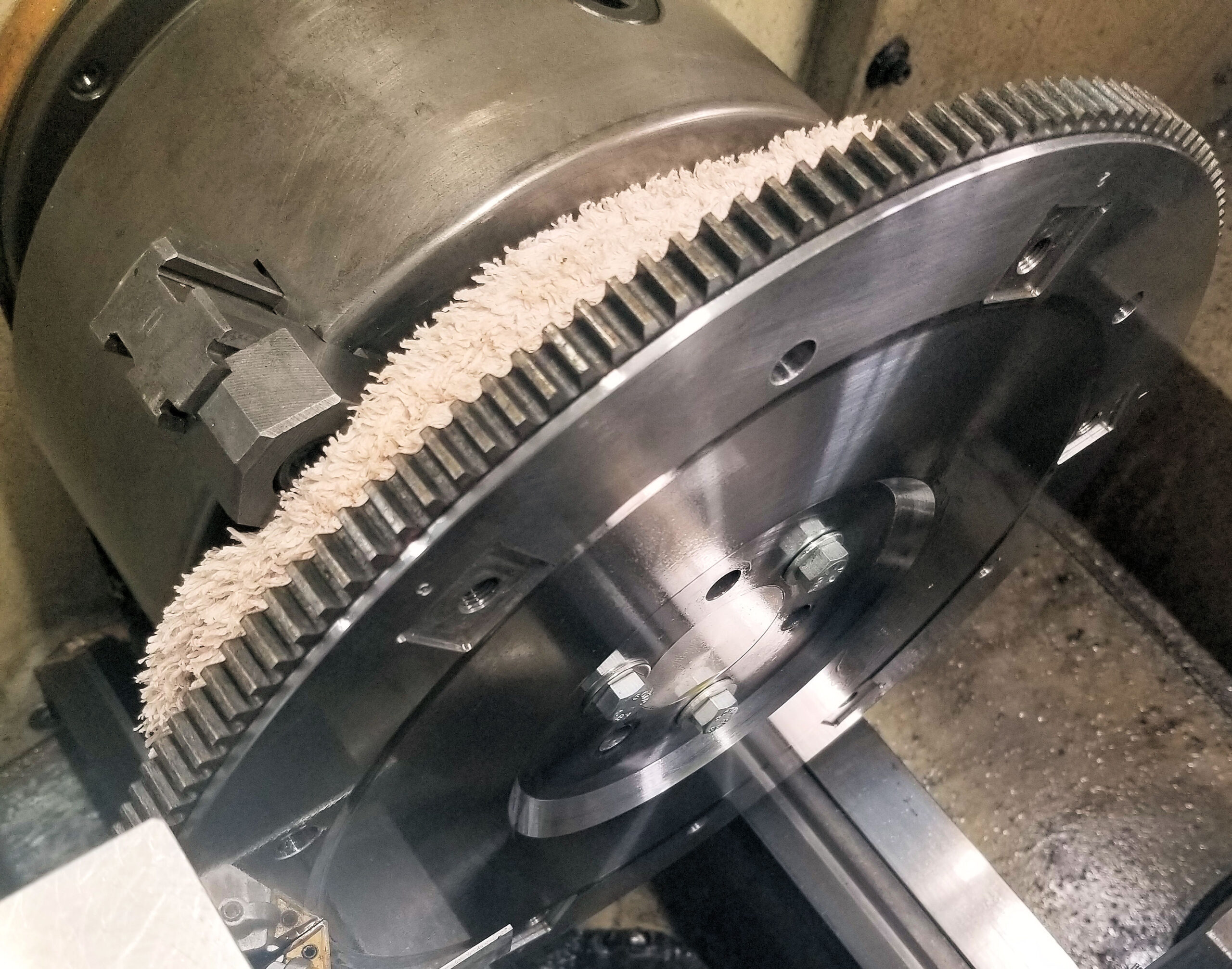

ANTI-VIBRATION TOWEL When machining or lightening a flywheel on a lathe, vibration and chattering will often cause a poor surface finish. To dampen the vibrations and achieve a nice smooth finish, soak a bath towel in water, wring it out and wrap the damp towel...

HEAVY METAL

Mar 1, 2021 | CRANKSHAFTS & CONNECTING RODS

HEAVY METAL When adding heavy metal to crankshafts, you always want a nice clean installation. I start with a slightly heavier slug than required and machine the center of the tungsten like a barbell to bring the crank into balance, instead of running it short in the...

MAKE IT BIGGER

Mar 1, 2021 | OTHER SHOP WORK

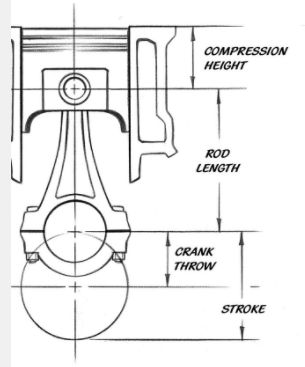

MAKE IT BIGGER Some engines are harder to increase the compression ratio on than others. Sometimes we are limited in cylinder head chamber size and sometimes higher compression pistons are not available or effective for certain engines. Increasing the crankshaft...