by Donnie Hurt | Jun 4, 2025 | BLOCK WORK

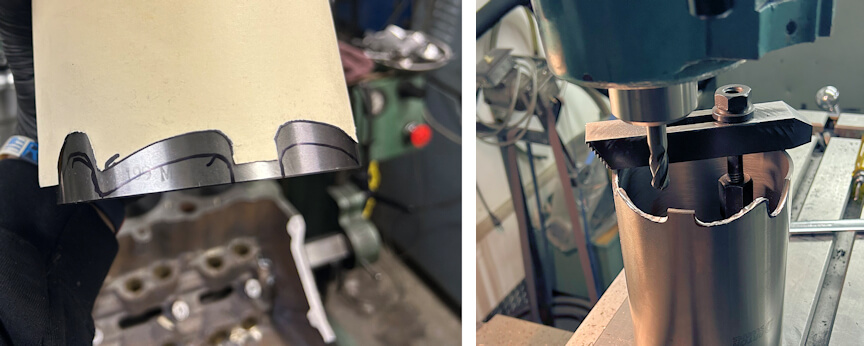

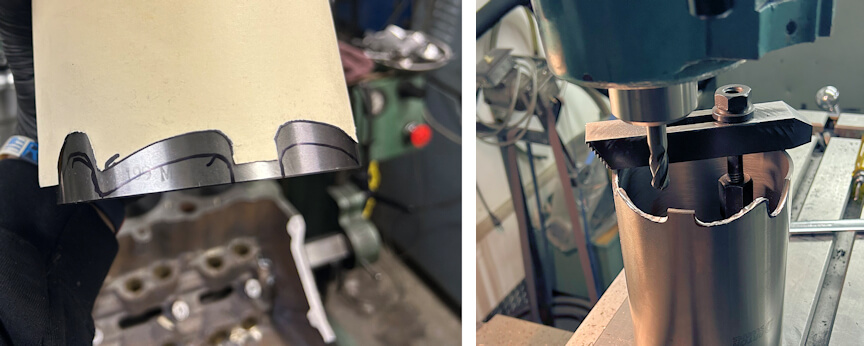

When sleeving blocks that have stroker clearance work done, I make a pattern from the bore ID and transfer it to the sleeve. This allows me to do most of the clearance work to the sleeve before installation using the mill. Find a reference mark on the block and draw...

by Donnie Hurt | May 6, 2025 | OTHER SHOP WORK

I once worked for Roy Johnson’s Automotive Machine Shop. This is where I was introduced to the use of common cooking lard as a lubricant when drilling on steel. Yes that’s right, now you’re cooking with “Bacon” in the shop. The use of the lard...

by Donnie Hurt | May 6, 2025 | CYLINDER HEADS

When grinding wire for fitting O-rings I use an air angle grinder and put a piece of shim stock between the head and wire to prevent bumping the grinding disc on the freshly machined head. Arus Kinney AK’s Engine and Machining Covington, GA...

by Donnie Hurt | May 6, 2025 | CAMSHAFTS & VALVE TRAIN

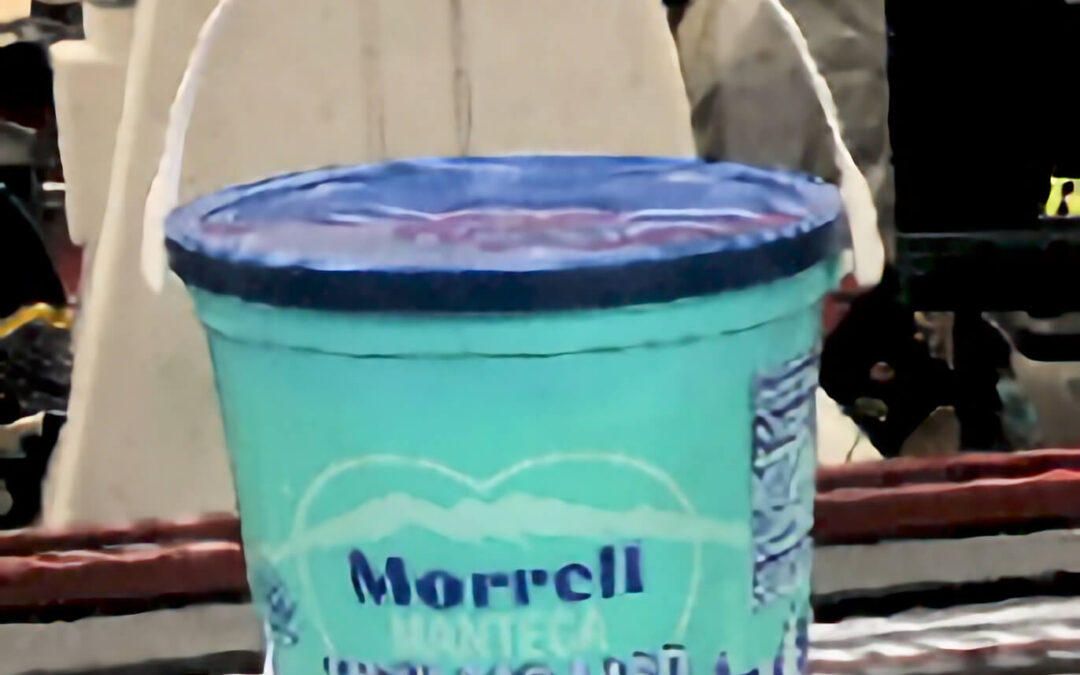

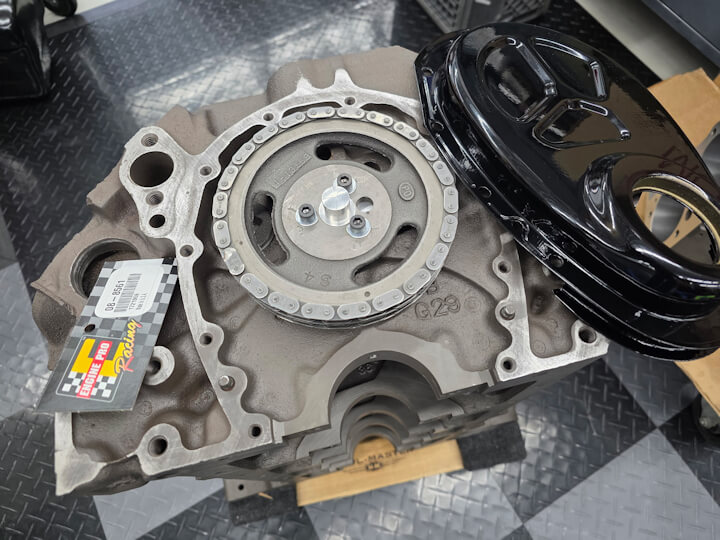

I have a cam gear with a chain for checking clearance on the top oil galley area on SB Chevy blocks, which is often an issue. This was a previous Shop Solution. I also use it to check or set-up cam button to timing cover clearance for my engine builders or home...

by Donnie Hurt | Apr 1, 2025 | BLOCK WORK

Sometimes when chasing the head bolt holes on Chevy blocks, you’ll hit a casting knob. Then you think, will the bolt thread in far enough. I use a 7/16 valve guide and some washers to mimic the cylinder head thickness. This saves time by not having to measure...