by Donnie Hurt | Nov 24, 2025 | OTHER SHOP WORK

It is a huge time-saver to attach a magnetic bar to your hoist to hold common lifting bolts. I also attached a swivel to the hook end to keep parts from twisting and bumping into things when lifted, and to make positioning easier. Arus Kinney AK’s Engine and...

by Donnie Hurt | Nov 1, 2025 | BLOCK WORK

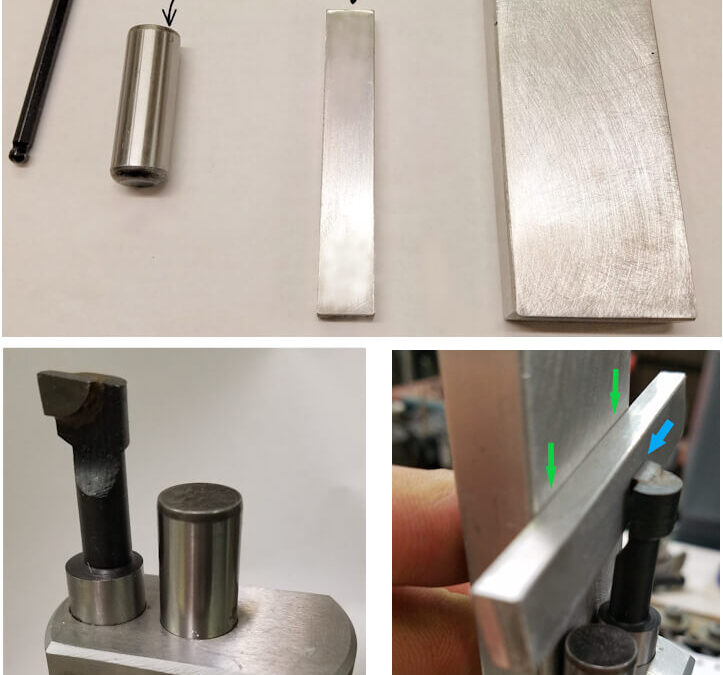

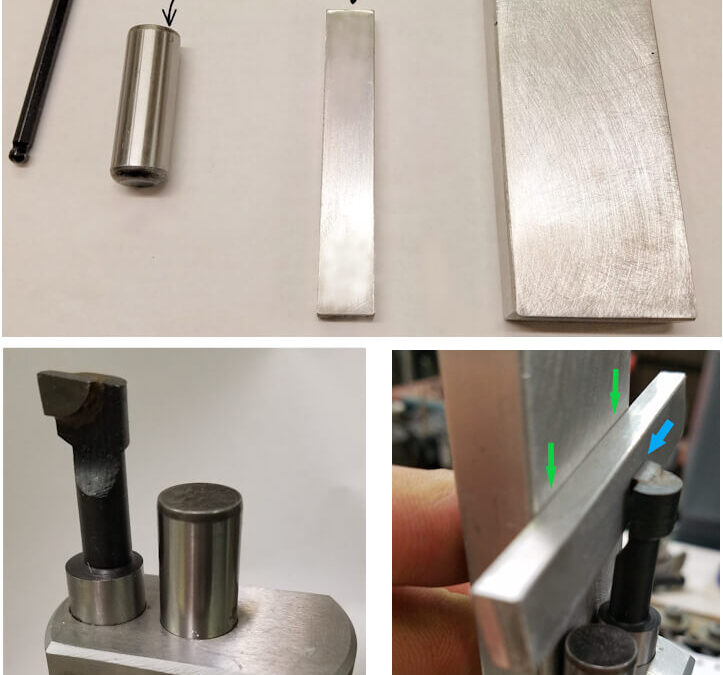

Here’s an easy way to precisely align or clock a boring tool in a boring head. You’ll need a dowel pin the same size as the tool shank to fit the boring head, a 1/4″ thick x 1/2″ aluminum flat bar, and a 1-1/2″ x 1/2″ aluminum flat...

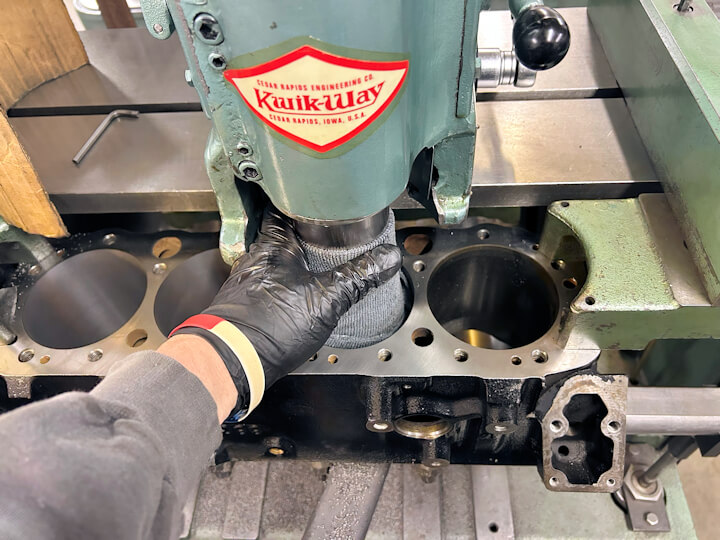

by Donnie Hurt | Oct 30, 2025 | BLOCK WORK

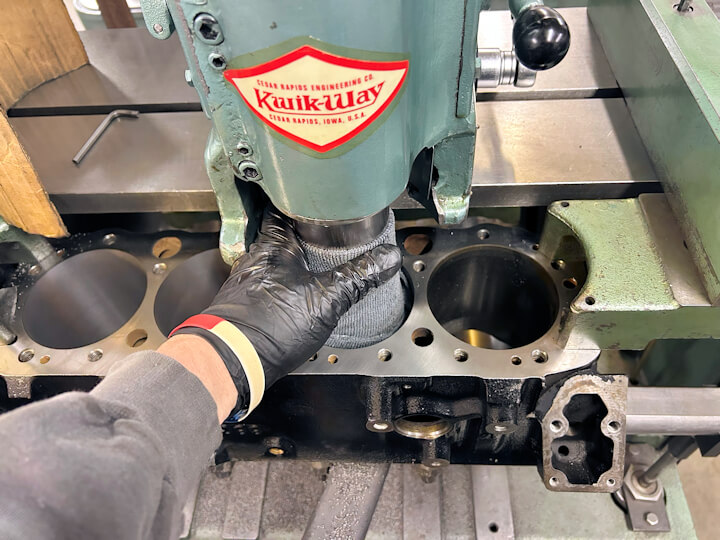

When boring blocks, in addition to a cardboard chip deflector and a vacuum cleaner running under it, I still wipe the bar down with a microfiber as it retracts. Just one more way to keep chips out of the column seal. Ron Flood Cedar Machine North Branch,...

by Donnie Hurt | Oct 13, 2025 | CYLINDER HEADS

Continual measuring takes time and doesn’t make any money. I take a measurement from the gasket surface on diesel heads before removing the guides. I use a large diameter disc, add balancer washers, ARP washers and whatever it takes to get the guide driver the...

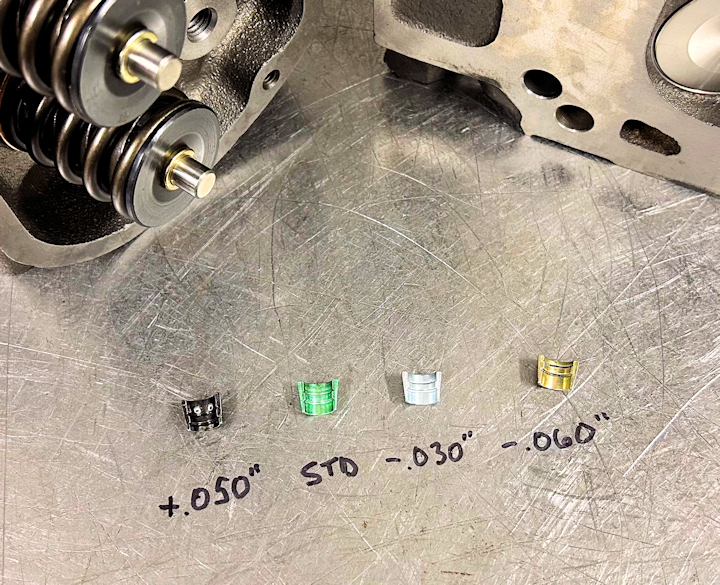

by Donnie Hurt | Oct 13, 2025 | CYLINDER HEADS

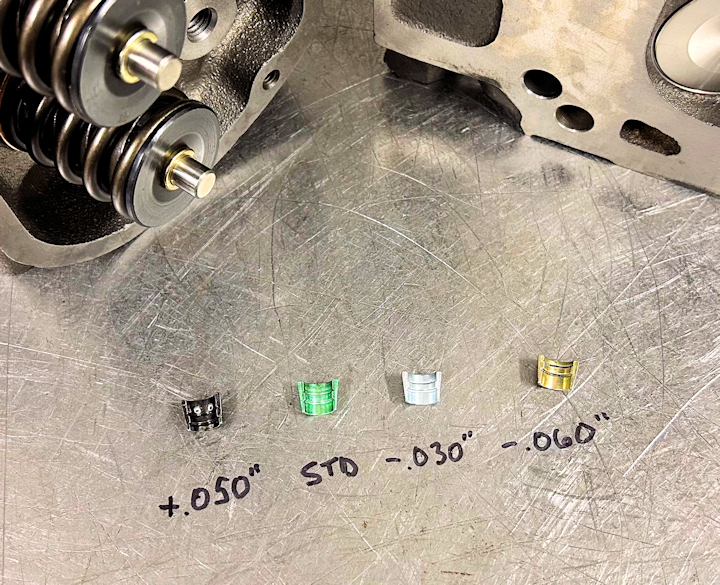

We all know how handy offset locks can be when setting up valve springs, and here are a couple tips regarding using them. With heavy spring pressures, I’d recommend against using positive height offsets, as you lose some support at the keeper groove, possibly...