by Donnie Hurt | Jul 14, 2025 | BLOCK WORK

When I’m boring a block, I draw a little line on the micrometer with a felt tip, once it’s set. This way I can see at a glance that I haven’t inadvertently loosened the lock screw and/or changed the setting. You don’t really have to focus in on...

by Donnie Hurt | Jul 14, 2025 | CAMSHAFTS & VALVE TRAIN

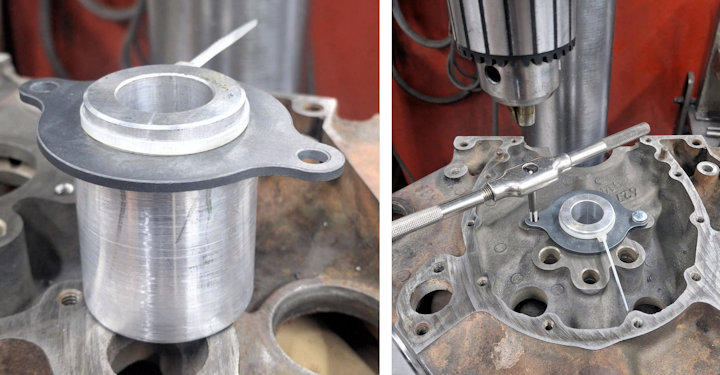

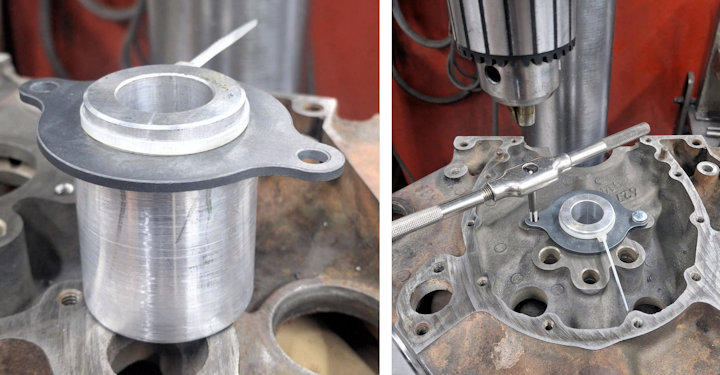

In order to correctly locate and drill a small block Chevy block for an O.E. cam thrust plate, we made a jig from an aluminum leaf spring bushing. It locates in the cam bearing bore, and the top is machined for the I.D. of the thrust plate. It works like a charm! Rich...

by Donnie Hurt | Jul 7, 2025 | CRANKSHAFTS & CONNECTING RODS

When I’m balancing a crank and need to add Mallory-metal, I chuck a marker or paint pen into the drill and peck a mark on the counterweight. Once I remove the crank to go to the mill to drill through the side, I have a nice reference for where to center the hole. Big...

by Donnie Hurt | Jul 3, 2025 | BLOCK WORK

It is good practice to lube up the main cap registers on aluminum blocks before seating the main caps. I have noticed the registers will peel aluminum when driving a steel main cap into place. Applying a thin layer of high-pressure grease to the cap and block will...

by Donnie Hurt | Jun 18, 2025 | GASKETS & SEALING

When I’m installing intakes using a composition gasket, I lightly coat the inside of the water ports with RTV gasket sealer. This prevents the coolant from soaking into the gasket and leaking over time. I use gasket sealant instead of gasket maker to allow the...