by Donnie Hurt | Jan 12, 2026 | OTHER SHOP WORK

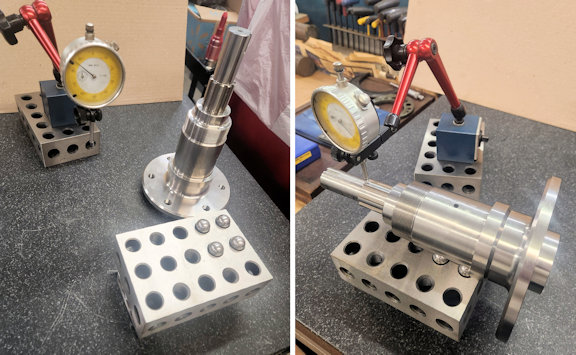

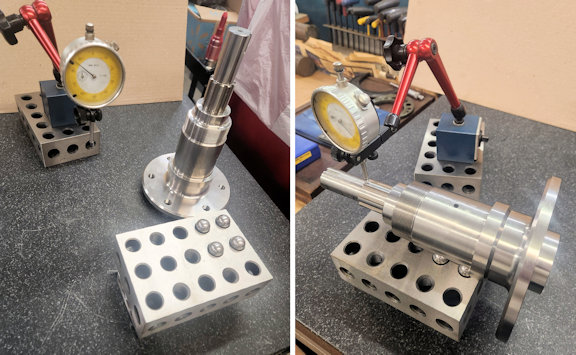

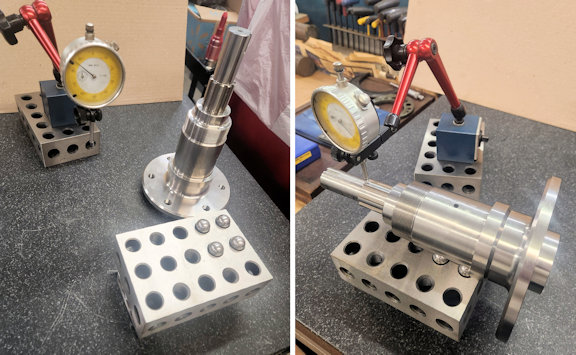

Here’s an easy fixture for inspecting run-out on shafts with a diameter too large to fit in your V-blocks. We place 2-4-6 blocks (or you can use a couple of 1-2-3 blocks) on our granite surface plate. You could also use a mill table. Next drop 4 steel ball bearings...

by Donnie Hurt | Jan 5, 2026 | TOOLING

I have a “snakey” set of 1.75″ headers on my hot rod truck. Several of the spark plugs are nearly impossible to access. I took an extra 5/8″ socket, though the concept would work regardless what size hex. I trimmed it down In the lathe and drilled a...

by Donnie Hurt | Jan 1, 2026 | ASSEMBLY

We all use different assembly lubricants for different areas of our projects. Just have many pill bottles with a smaller hole in the cap to prevent spilling if it gets tipped over. Just fill the bottle with a smaller level of lube so it won’t pour out the top...

by Donnie Hurt | Jan 1, 2026 | LUBRICATION & COOLING

I’ve never trusted aftermarket pan volumes. If you are using the factory dipstick and tube, it’s not an issue, but with aftermarket or locking dipsticks, it’s a guess at best. I set a factory oil pan and the aftermarket pan between milk crates. I put 4...

by Donnie Hurt | Dec 9, 2025 | ASSEMBLY

This is a customer’s balancer, though the procedure will work on a new one with the rubber bonded outer ring. I make a groove that runs down to the center hub. I use a chisel or a cut-off wheel, then I take a pick with yellow paint and mark the line. Should this...