by Donnie Hurt | Feb 1, 2025 | CYLINDER HEADS

I had some FE heads with some pretty decent burrs on the valve tips. Instead of slowly turning the valves by hand to file the burrs off, I grabbed an old valve lapping stick and chucked it up in the drill to spin the valves. It went really quickly, and I was able to...

by Donnie Hurt | Dec 23, 2024 | CYLINDER HEADS

When valve train clearances are going to be tight, I like to double check my measurements and bench calculations by actually testing the components after they’re assembled. I put the valves and springs in this head, then used my quill on the seat & guide...

by Donnie Hurt | Dec 18, 2024 | CYLINDER HEADS

Sometimes assembling heads with beehive springs and retainers can be difficult because of their size. I find it easier to use a spring shim that fits the retainer and large enough to fit the spring compressor jaws. Randy Torvinen Torvinen’s Machine Menahga,...

by Donnie Hurt | Oct 8, 2024 | CYLINDER HEADS

When you’re grinding Titanium valves, if you want a super shiny finish, grind them with the green wheel and “Mirror finish”. Wipe them off before pulling them from the chuck and give them 30 seconds of spinning with a microfiber towel and some...

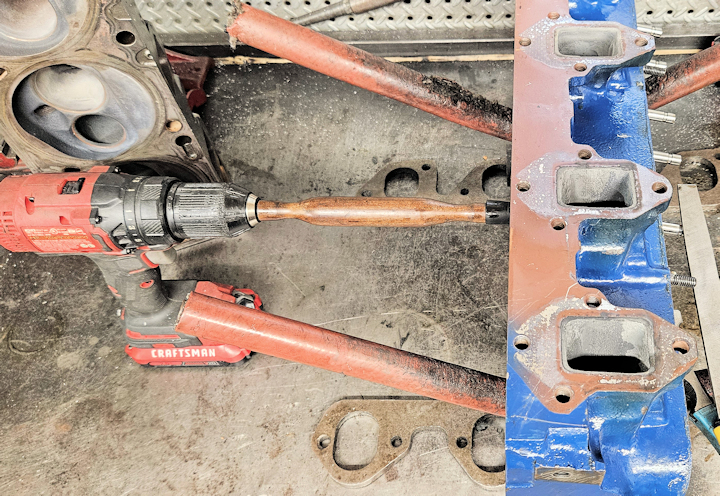

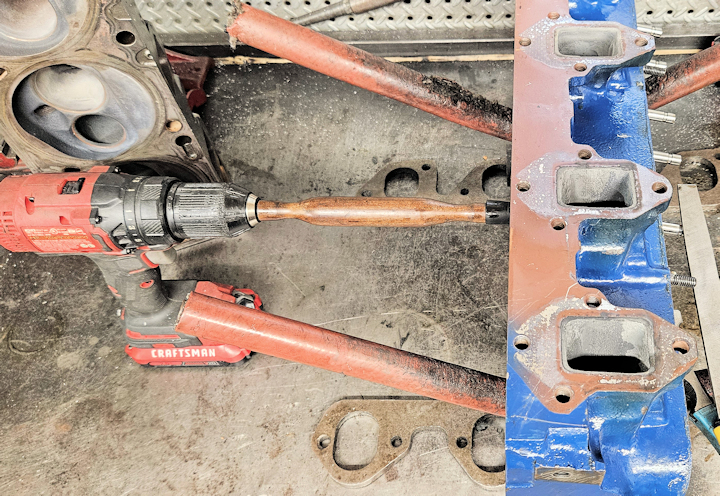

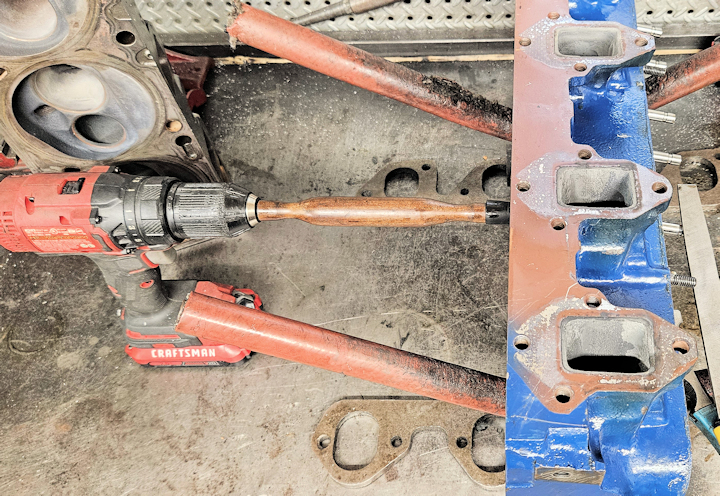

by Donnie Hurt | Aug 9, 2024 | CAMSHAFTS & VALVE TRAIN

When checking valve train geometry, you need adjustable pushrods which are never the right length and you need to use a light spring. I bought 1 of every 3/8 .080 wall pushrod 7.00” to 12.00”, in .050” length increments. It makes checking geometry quick and easy. Bob...