by Donnie Hurt | Nov 1, 2021 | DISASSEMBLY & CLEANING

GET YOUR BEARINGS When baking and shot peening cylinder blocks, I leave the main bearing shells and the cam bearings in the block to protect surfaces and maintain concentricity. Anthony Rotella Anthonys Marine & Service St Petersburg, FL NOVEMBER,...

by Donnie Hurt | Nov 1, 2021 | TOOLING

SHARPENER If you have one of these style sharpeners, we have found the rest and stop can be adjusted to sharpen your drill bits on the appropriate angle, for a sharp tip every time. Adam Cofer Don Ott Racing Engines York Springs, PA NOVEMBER,...

by Donnie Hurt | Nov 1, 2021 | BLOCK WORK

BLOCK SQUARED For those using the common block deck indexing fixture, heres an easy way to check accuracy of the front plate. When you finish squaring up a block. Flip the plate backwards and check the deck across the surface to the plate again. It should read the...

by Donnie Hurt | Nov 1, 2021 | TOOLING

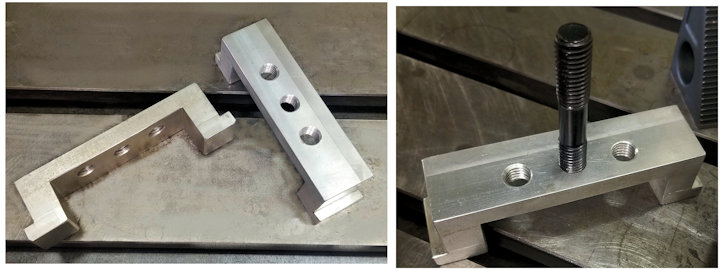

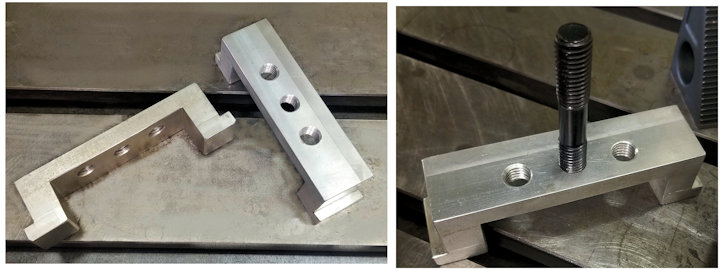

T-SLOT BRIDGE Occasionally, when clamping an odd-shaped part like a cylinder head or small engine block on our Bridgeport mill, the mill table’s T-slots are not always spaced for convenient clamping. To make the job easier and faster, we machined a pair of steel...

by Donnie Hurt | Nov 1, 2021 | OPERATIONS

TRACKING WORK ORDERS Because we have a stack of work orders, about an inch thick, we have a system that helps us match a customer with their job, when they call. The work orders are kept in numerical order on a clipboard. The customer is assigned a work order number,...