by Donnie Hurt | Jun 20, 2019 | LUBRICATION & COOLING

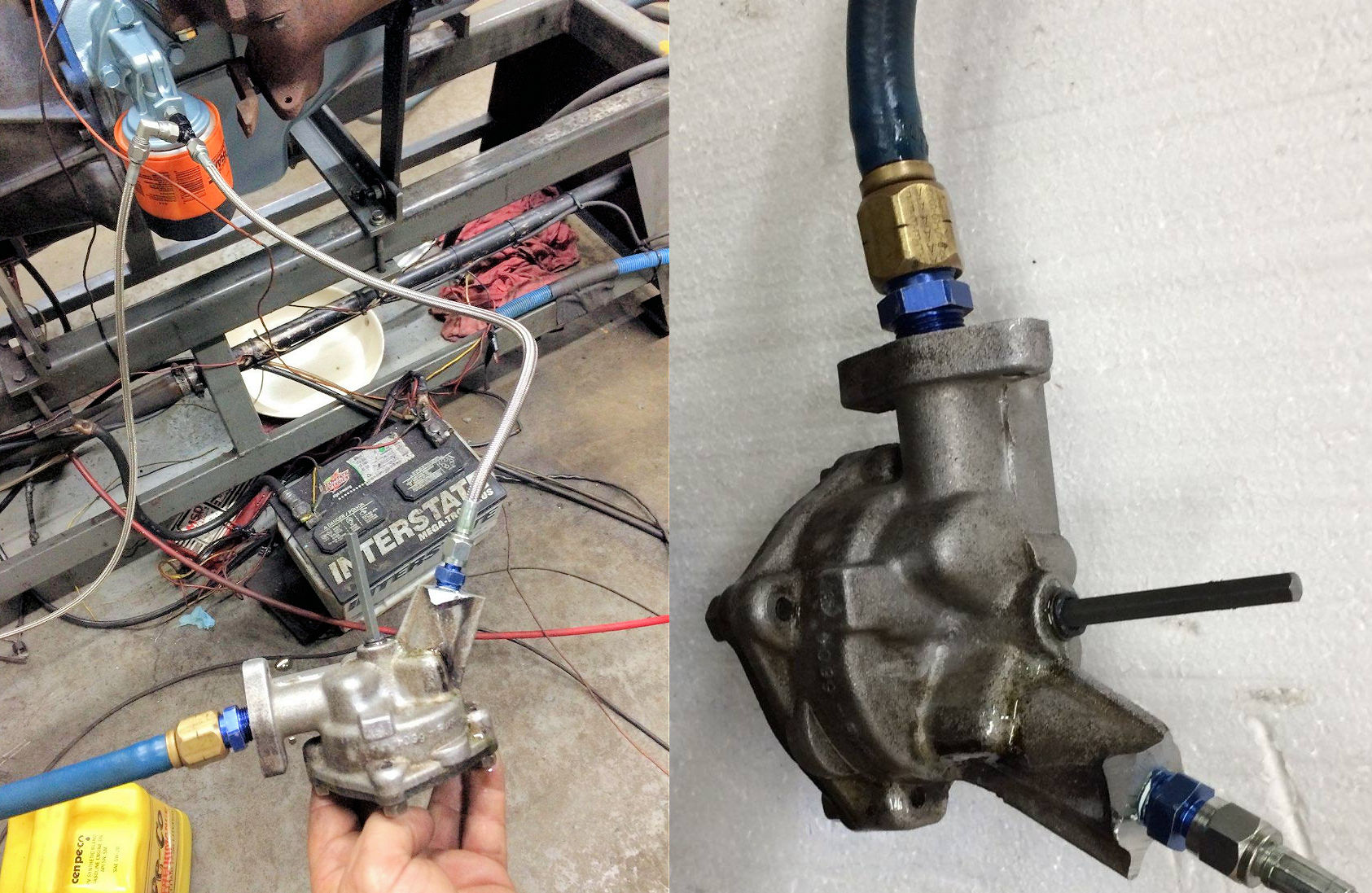

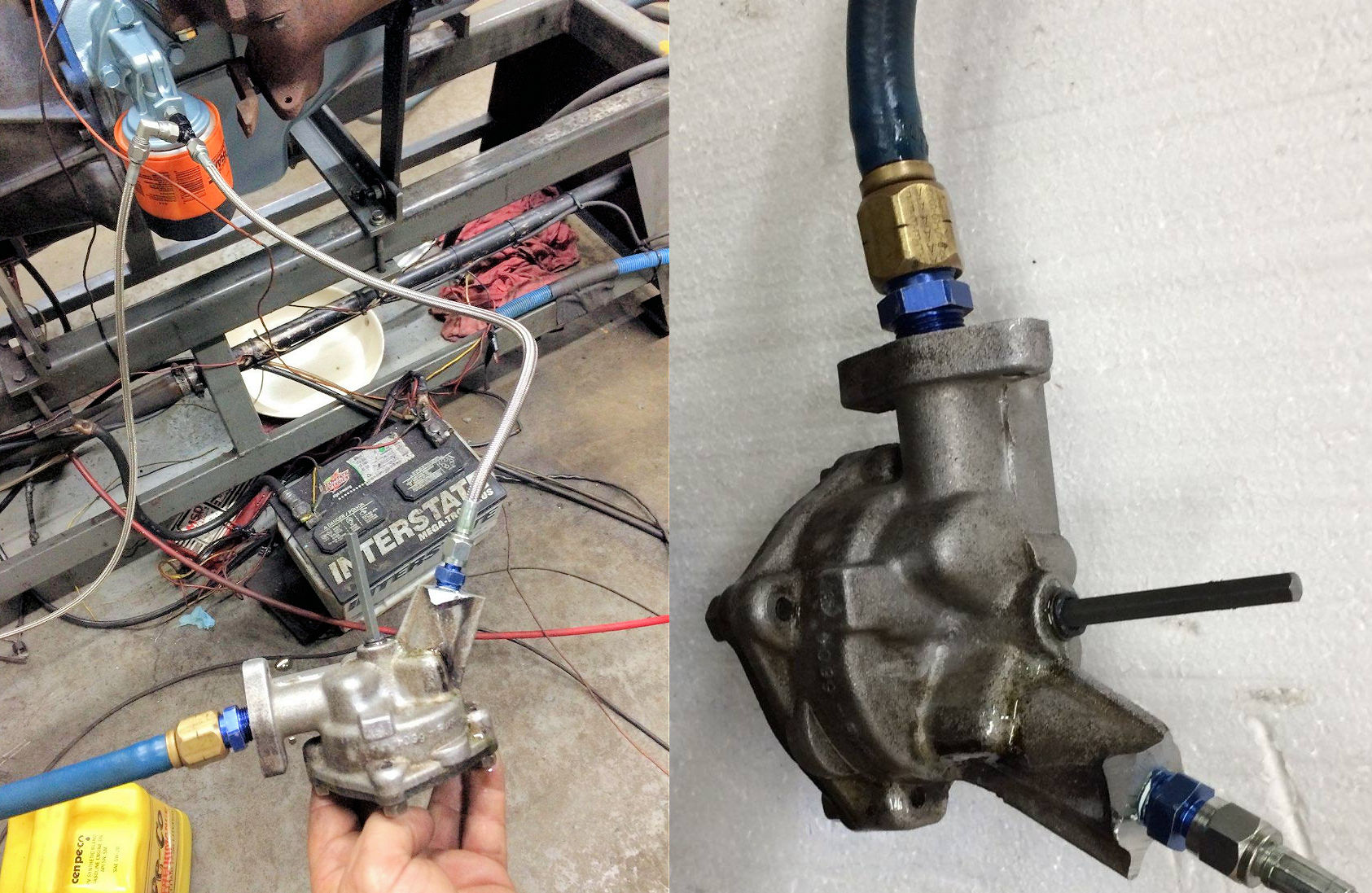

OIL PUMP INTO OIL PRIMER I was looking at purchasing an oil reservoir tank type oil system primer but thought there might be another way. I had just rebuilt an early SB Ford and still had the old school aluminum oil pump. It was very easy to cut off the mounting neck....

by Donnie Hurt | Jun 20, 2019 | TOOLING

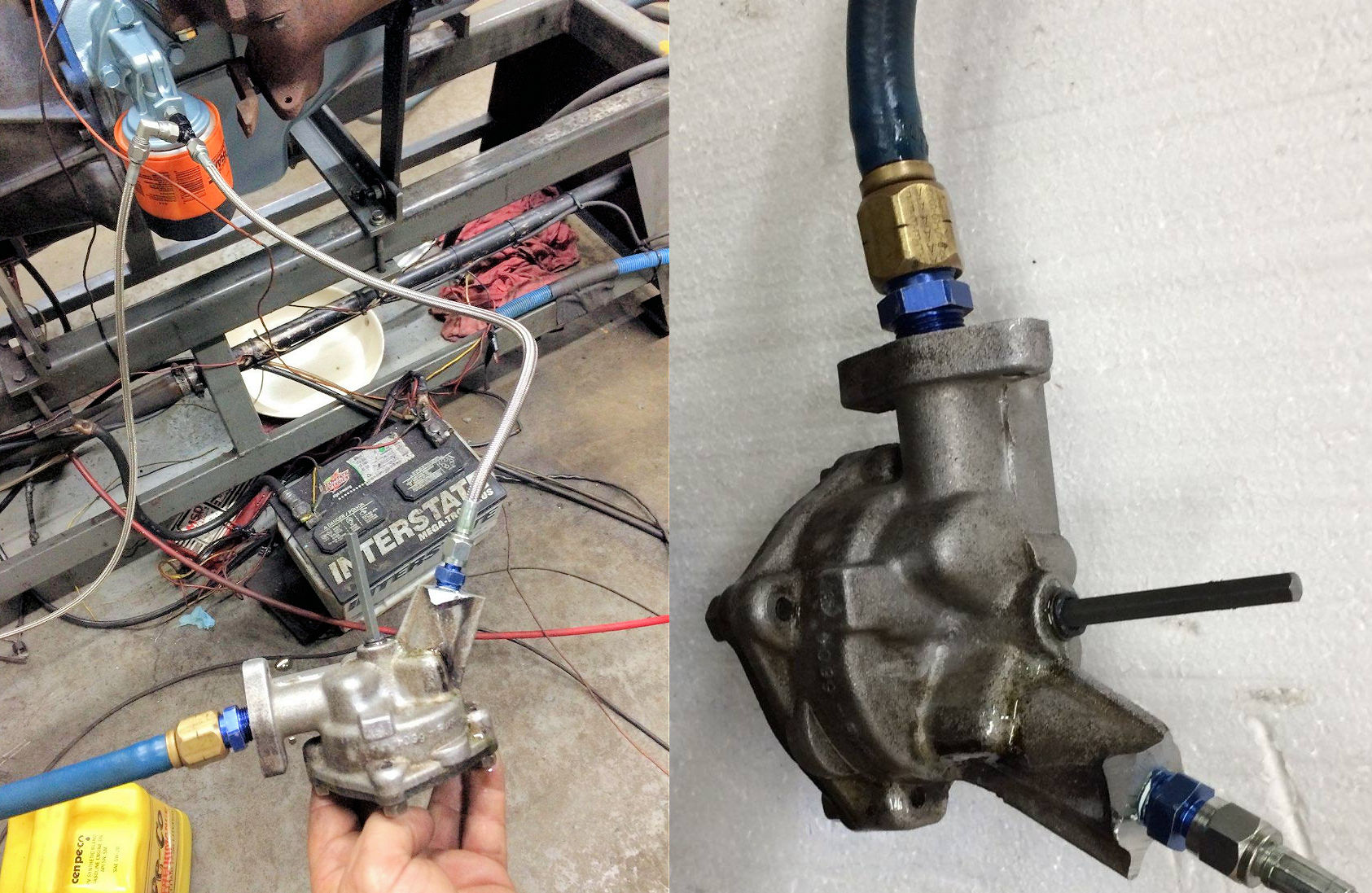

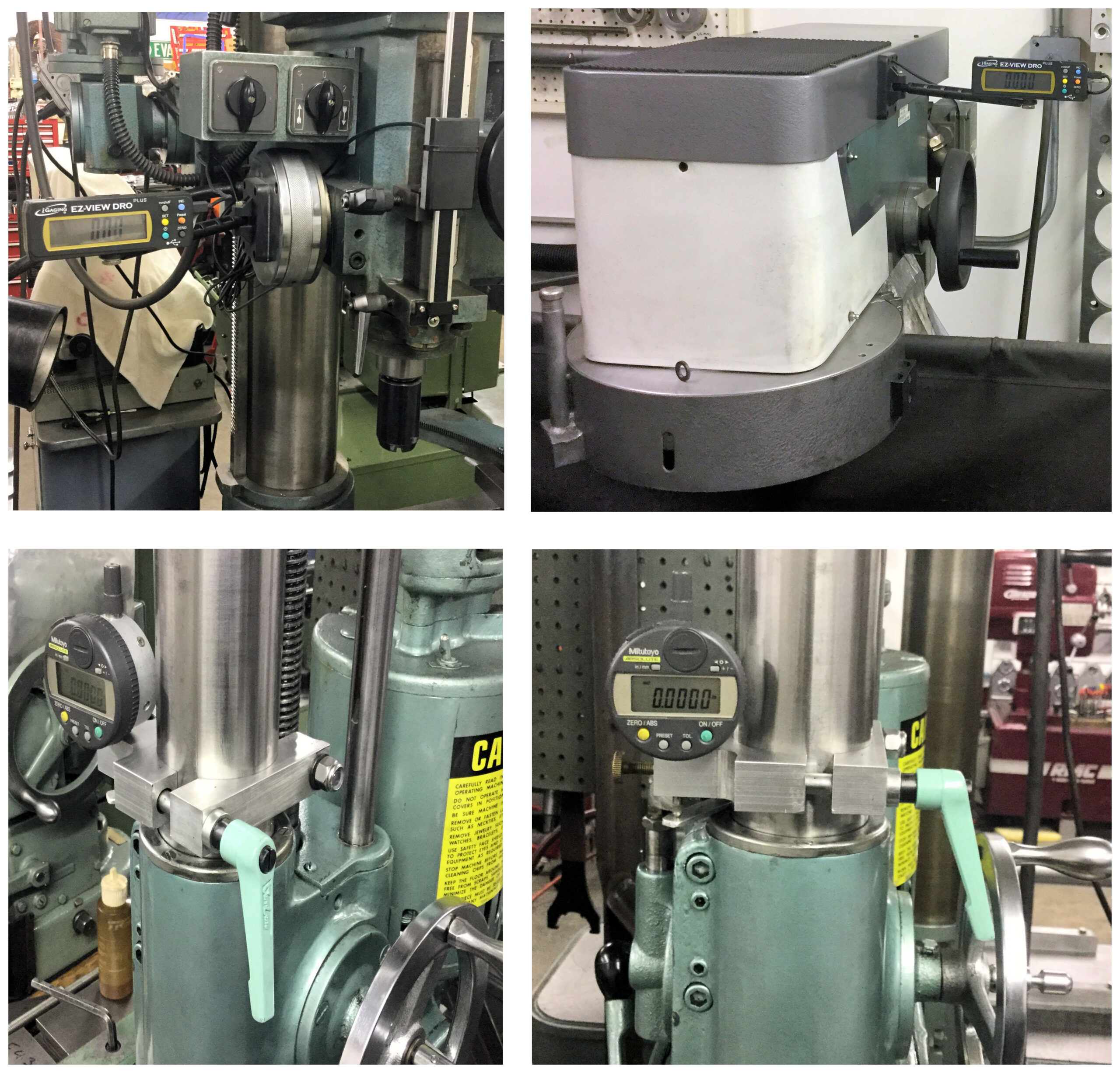

DIGITAL READ OUTS Here are some inexpensive digital read outs (DRO) I’ve added to various machines in the shop. On the seat and guide machine it’s great to be able to set seat depths for different cutters on the same head without setting the end stop for each one. You...

by Donnie Hurt | Jun 20, 2019 | CYLINDER HEADS

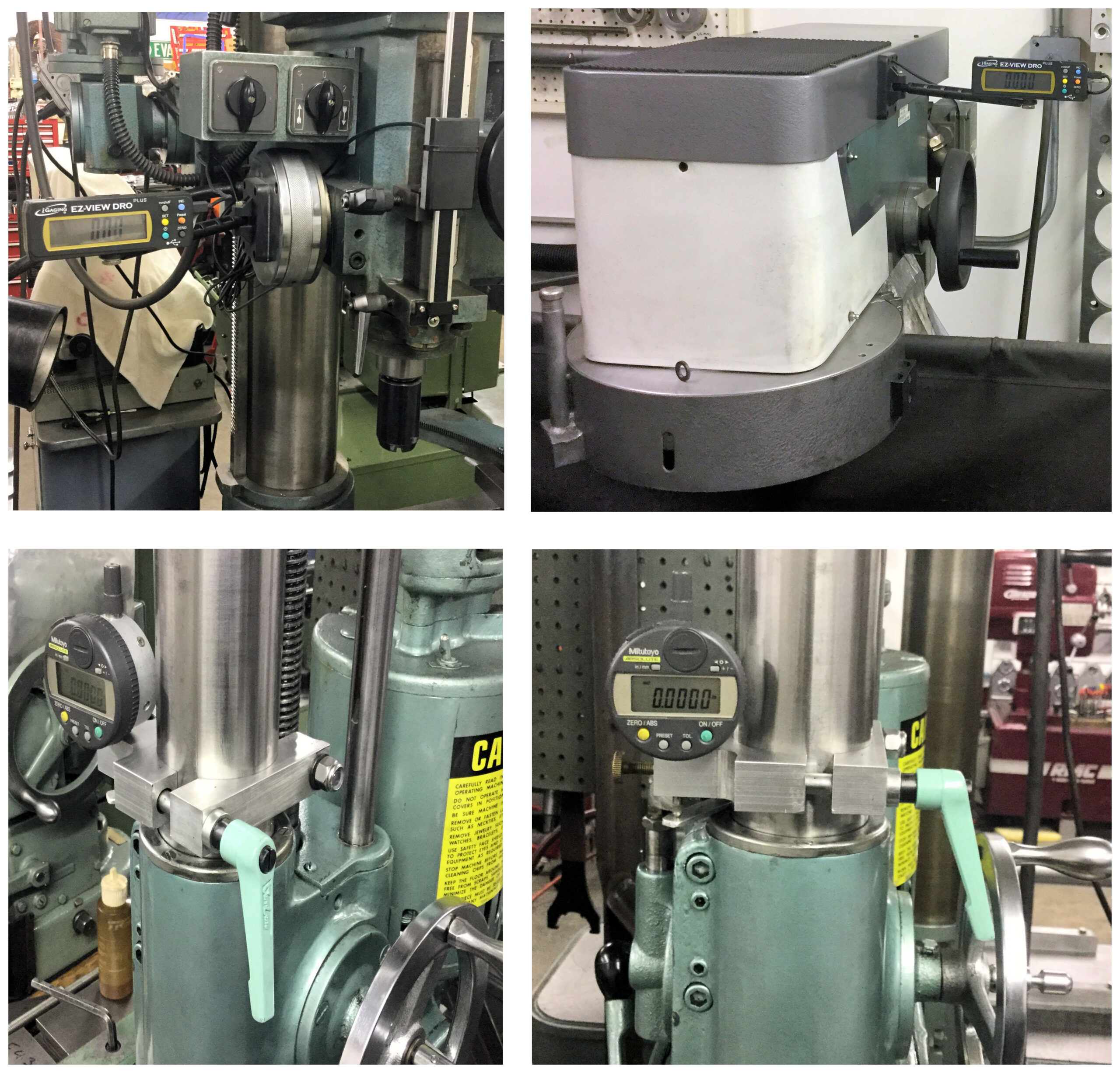

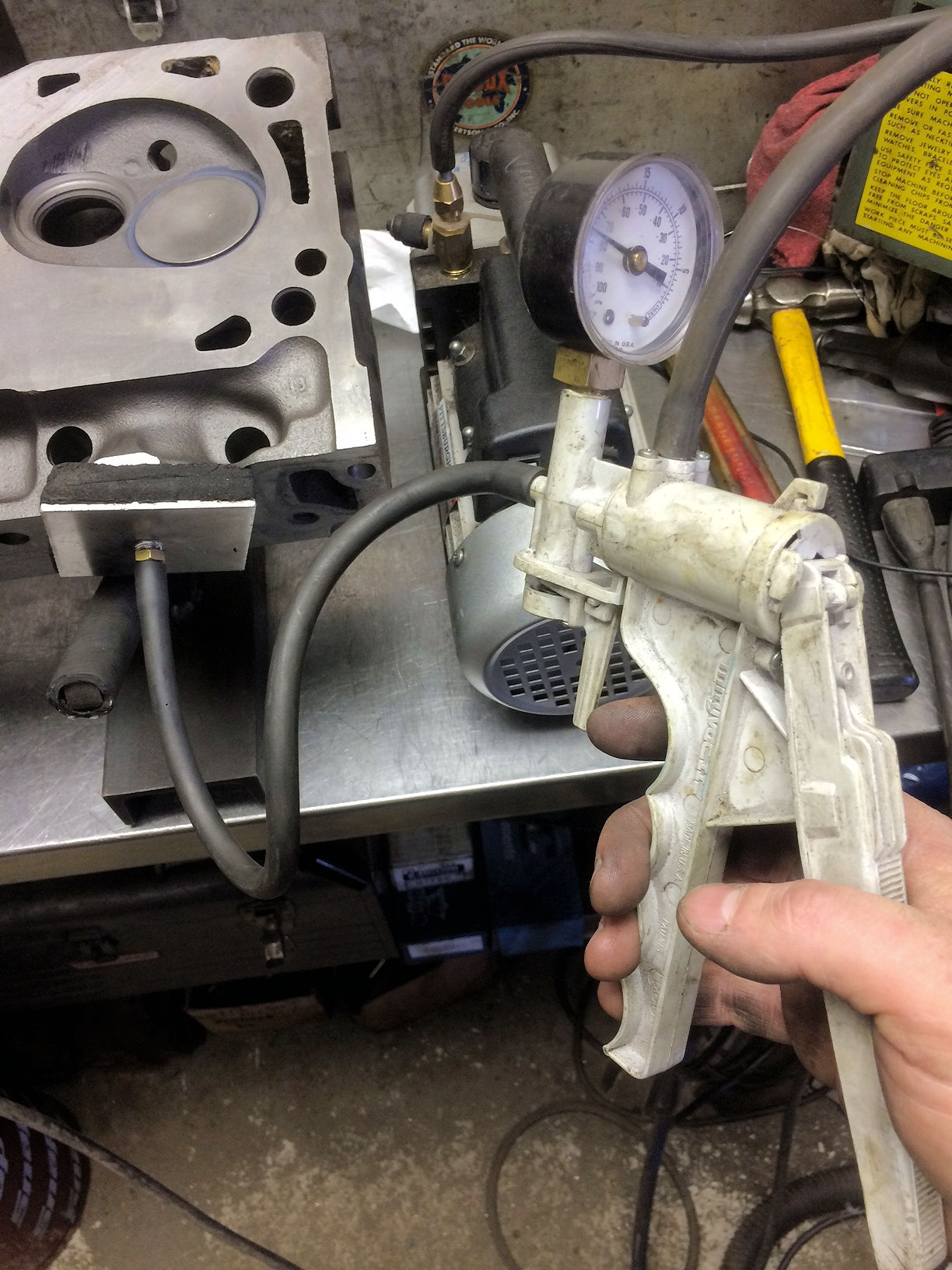

MODIFIED VACUUM TESTER We all use vacuum to test valve to seat seal. I use a handheld Mityvac in conjunction with an electric vacuum pump. By taking the vent cap off top of Mityvac, I was able to hook the pump directly to it. Now I have the ability to apply, hold and...

by Donnie Hurt | Jun 1, 2019 | PISTONS & RINGS

MODIFIED OIL RAILS When file fitting rings I also like to add a radius to the backside of the oil ring support rails, at the gap. I rough in the radius on the belt sander and then finish it on the debur wheel on my ring grinder. Without adding this radius to the...

by Donnie Hurt | Jun 1, 2019 | ASSEMBLY

“CLEANLINESS IS NEXT TO GODLINESS” You would not think of warrantying a newly rebuilt engine if the customer bolted on a dirty oil pan, crusty pick up screen, old sludge filled valve covers or even a Chevy intake manifold the was losing carbon out of the...