BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

REAR MAIN PAIN

May 2, 2018 | GASKETS & SEALING

REAR MAIN PAIN We are still getting lots of calls on rear main seal leaks on LS engines after rebuilds. We suggest engine builders install the rear seal with the lip facing the crankshaft, like all other engines, regardless of installation instructions. This change in...

PISTON CLAMP

May 2, 2018 | PISTONS & RINGS

PISTON CLAMP Eliminating the movement of the parts when installing or removing Spirolox type retaining rings makes the job easier. This device, simply made, stabilizes the assembly and/or removal. Instead of clamping a connecting rod in a vise and trying to steady...

GM AFM VLOM

May 1, 2018 | CAMSHAFTS & VALVE TRAIN

GM AFM VLOM The GM Active Fuel Management, or AFM Engines in 2005-2014 5.3L and 6.0L Passenger Cars, Trucks and SUVs are prone to lifter failures. These lifters are expensive and labor intensive to replace. As is common with lifter failures, the lifter usually gets...

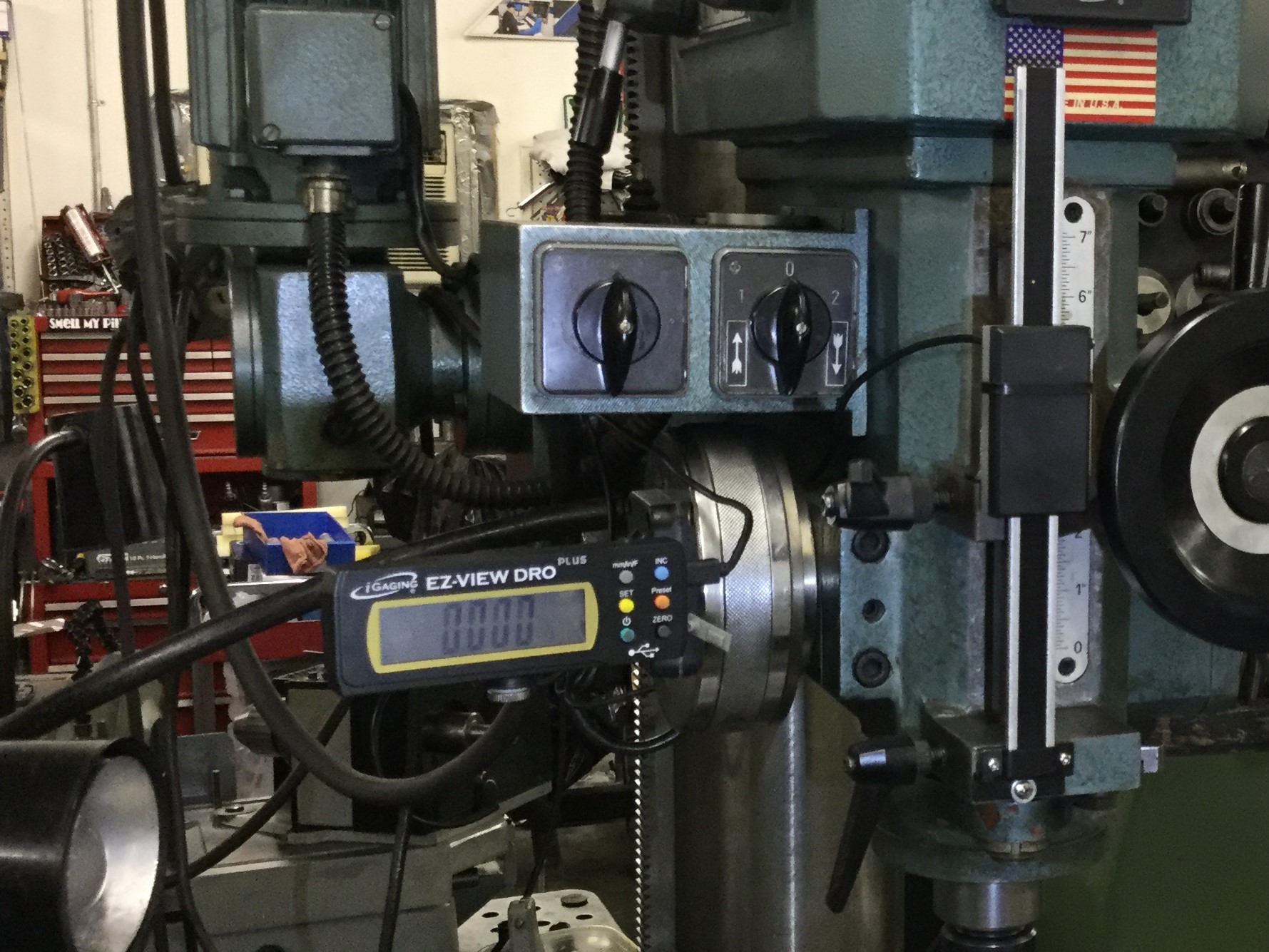

A BIT OF KNOWLEDGE

Apr 20, 2018 | TOOLING

A BIT OF KNOWLEDGE Three tips to make your drill bits last longer.1. choose the right bit. A black oxide coated bit helps reduce friction and increase chip flow but shouldn’t be used on nonferrous materials. TiN is a titanium nitride with a gold color that can run...

SUBARU HEAD GASKET TECH

Apr 12, 2018 | GASKETS & SEALING

SUBARU HEAD GASKET TECH The EJ series 2.5l boxer engine has been powering many Subaru vehicles since 1996. With many different variations, they all share the potential for developing head gasket leaks. O.E.M. gaskets were composite or early generation MLS designs,...

SEAT CUTTING TIPS

Apr 5, 2018 | CYLINDER HEADS

SEAT CUTTING TIPS When cutting in valve seats with a single, multi angle blade, especially new ones, try to do the least amount of work with the profile tool as possible. For instance, if the bottom angle is 75°, cut as much of the seat away as you can with that...