by Donnie Hurt | Mar 1, 2016 | OPERATIONS

HANDLING UNHAPPY CUSTOMERS You can tell the customer interaction will be a tough one in the first few seconds. The caller’s tone of voice, accusatory language and high volume all say, “I’m going to let you have it”. How you react in these first few seconds will set...

by Donnie Hurt | Feb 1, 2016 | CRANKSHAFTS & CONNECTING RODS

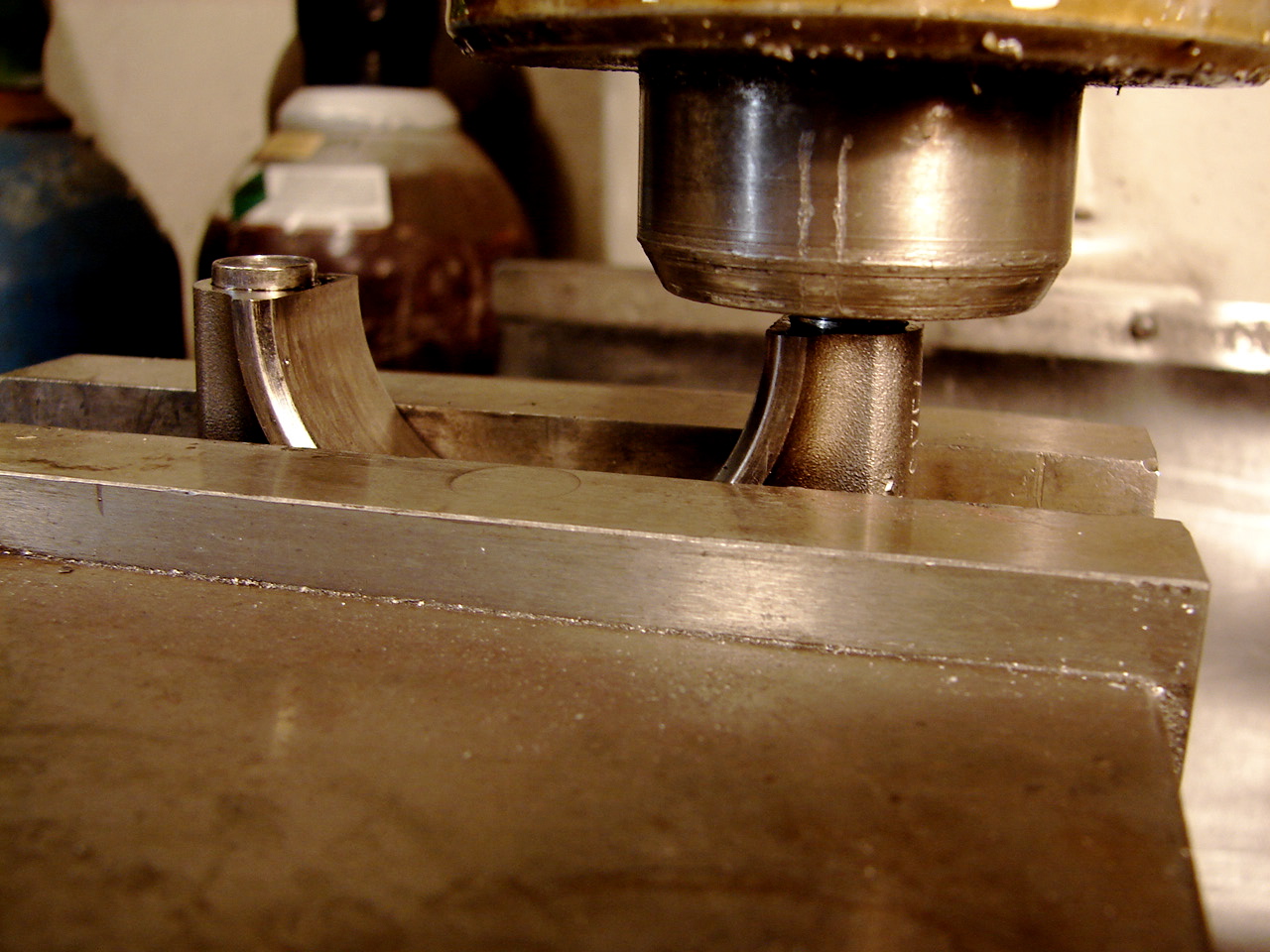

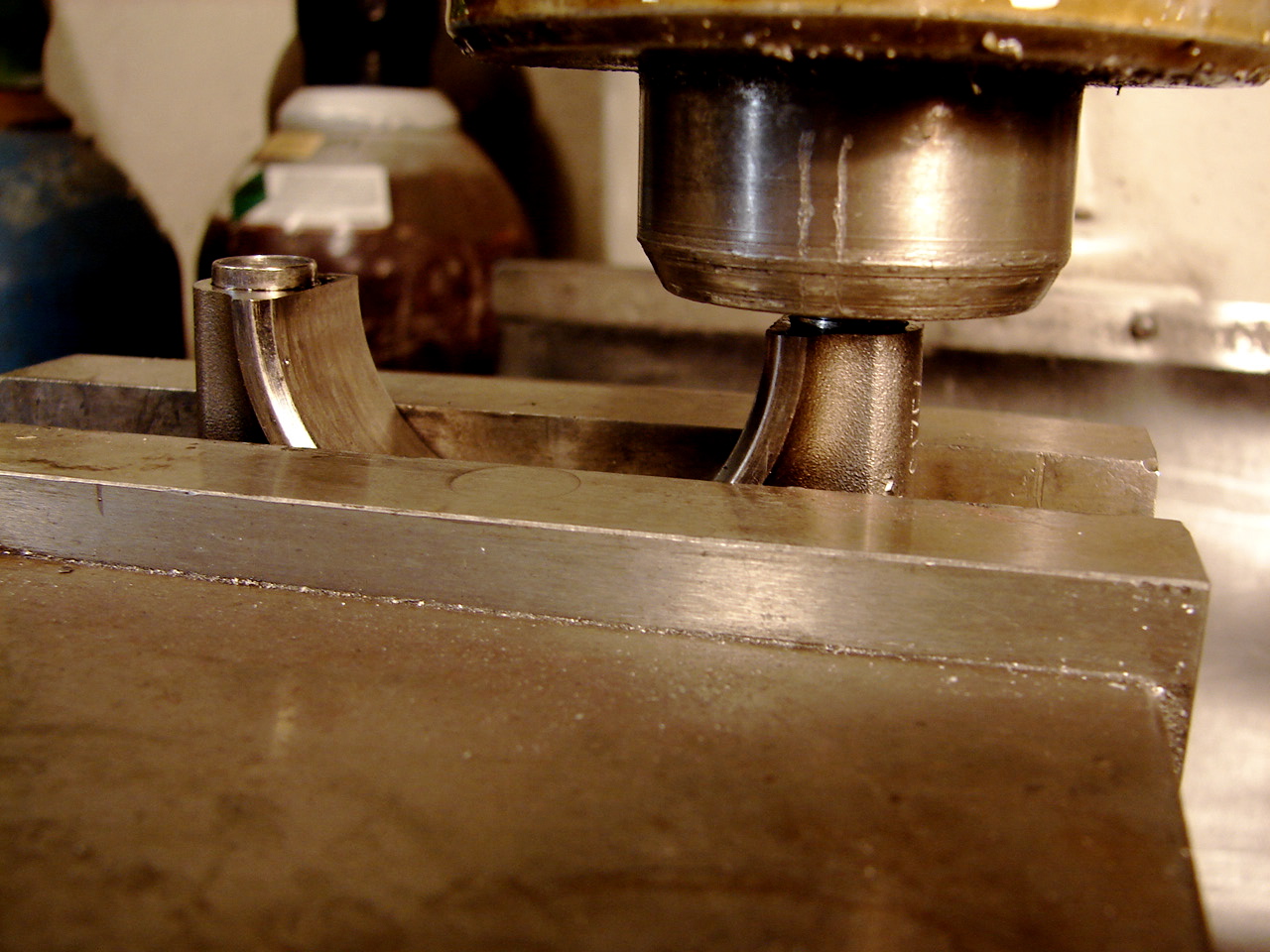

ANOTHER DOWEL PULLER We were trying to remove the alignment dowels from some “H” beam rods and our usual method of using a head dowel puller wasn’t working on the stubborn ones. I was trying to figure out a more precision collet set to use when I decided that my mill...

by Donnie Hurt | Feb 1, 2016 | OPERATIONS

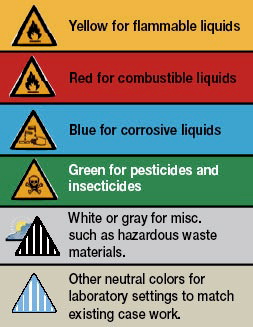

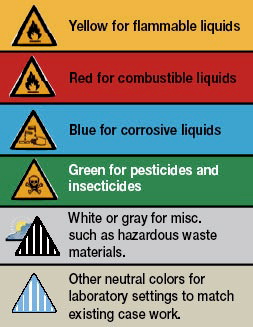

LET’S GET VISUAL ”Visuals” not only help eliminate waste, but can have additional positive impact on a shop’s operation, safety and cost. *Safety glasses (with side shields) should be mandatory in all shop areas; not just machining, grinding, welding, etc.. This can...

by Donnie Hurt | Feb 1, 2016 | OTHER SHOP WORK

E-Z BOLT REMOVAL Most bolts broken off flush or slightly below the surface can be easily removed using a MIG welder. Place a flat washer the same size as the broken bolt over the bolt and weld through the center. Then, place a 1⁄2” nut on top of the washer and...

by Donnie Hurt | Feb 1, 2016 | OTHER SHOP WORK

SMALL HONE ADAPTOR My shop does not get a lot of requests for small engine work so when I did get a small engine project I would just grab my Sunnen model JN small engine hone and low RPM drill and manually hone the small engine cylinder to size. After holding on to...