by Donnie Hurt | Mar 1, 2019 | ASSEMBLY

VACUUM UP OVERSPRAY Sometimes I end up having to paint an engine and don’t really have a dedicated place to do so. I put down a plastic painters drop sheet and paint the parts while guiding a shop vac hose in close proximity to where I’m spraying. A foot or so away is...

by Donnie Hurt | Mar 1, 2019 | OPERATIONS

REFERRAL REWARDS CUSTOMER AND BUSINESS Rewarding existing customers when they share your services with a friend is a great way to generate new business. There are lots of ways to organize a referral program, including some cool eCommerce plug-ins for your website....

by Donnie Hurt | Mar 1, 2019 | GASKETS & SEALING

TOUGH ROPE Modern rope seal materials are much tougher than the old asbestos types and are nearly impossible to cut clean. I found that a Dremel tool with a small cutoff wheel will give the best and cleanest cut with the least amount of effort. Gary Hennen Magnum...

by Donnie Hurt | Feb 1, 2019 | CYLINDER HEADS

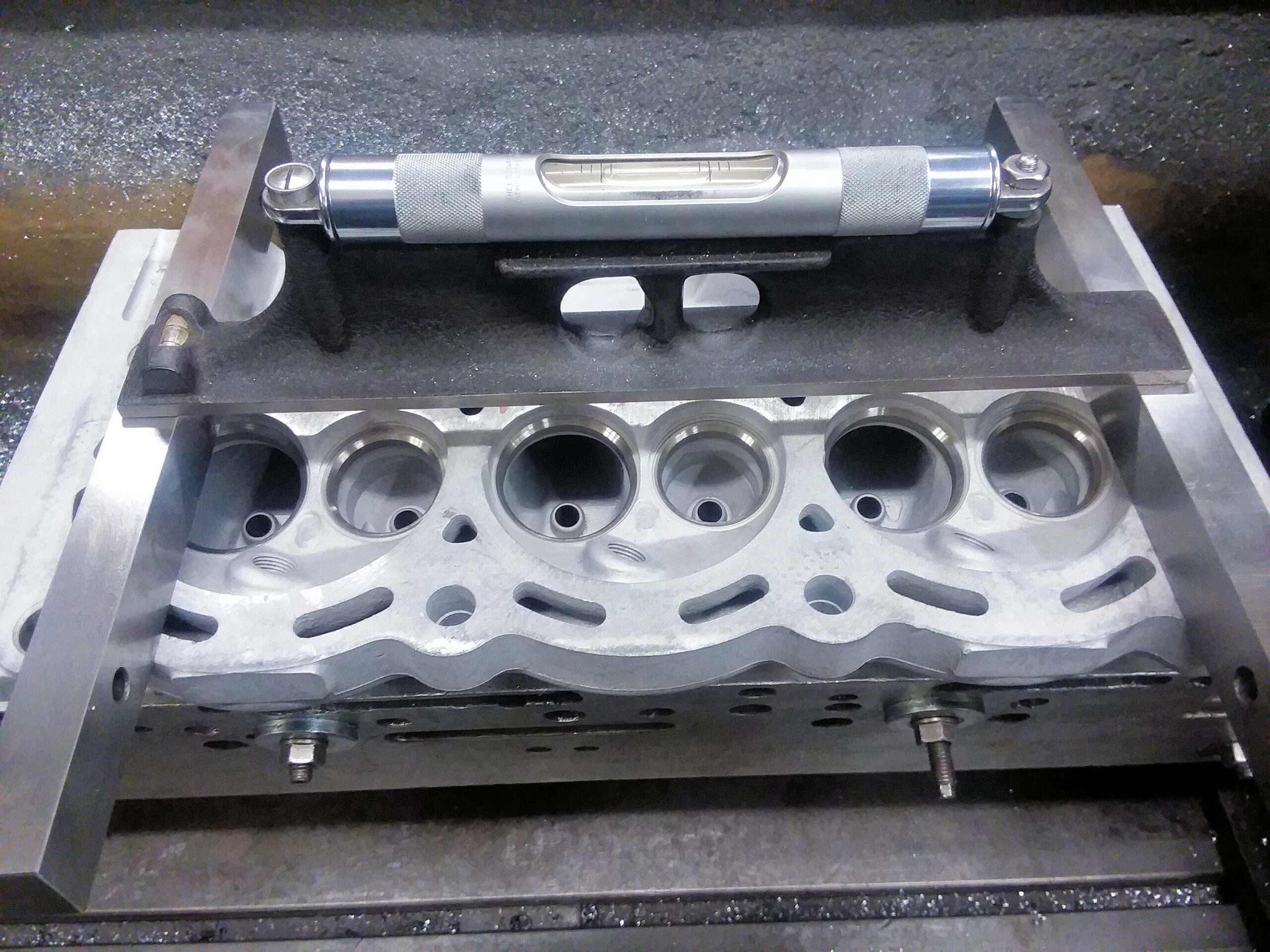

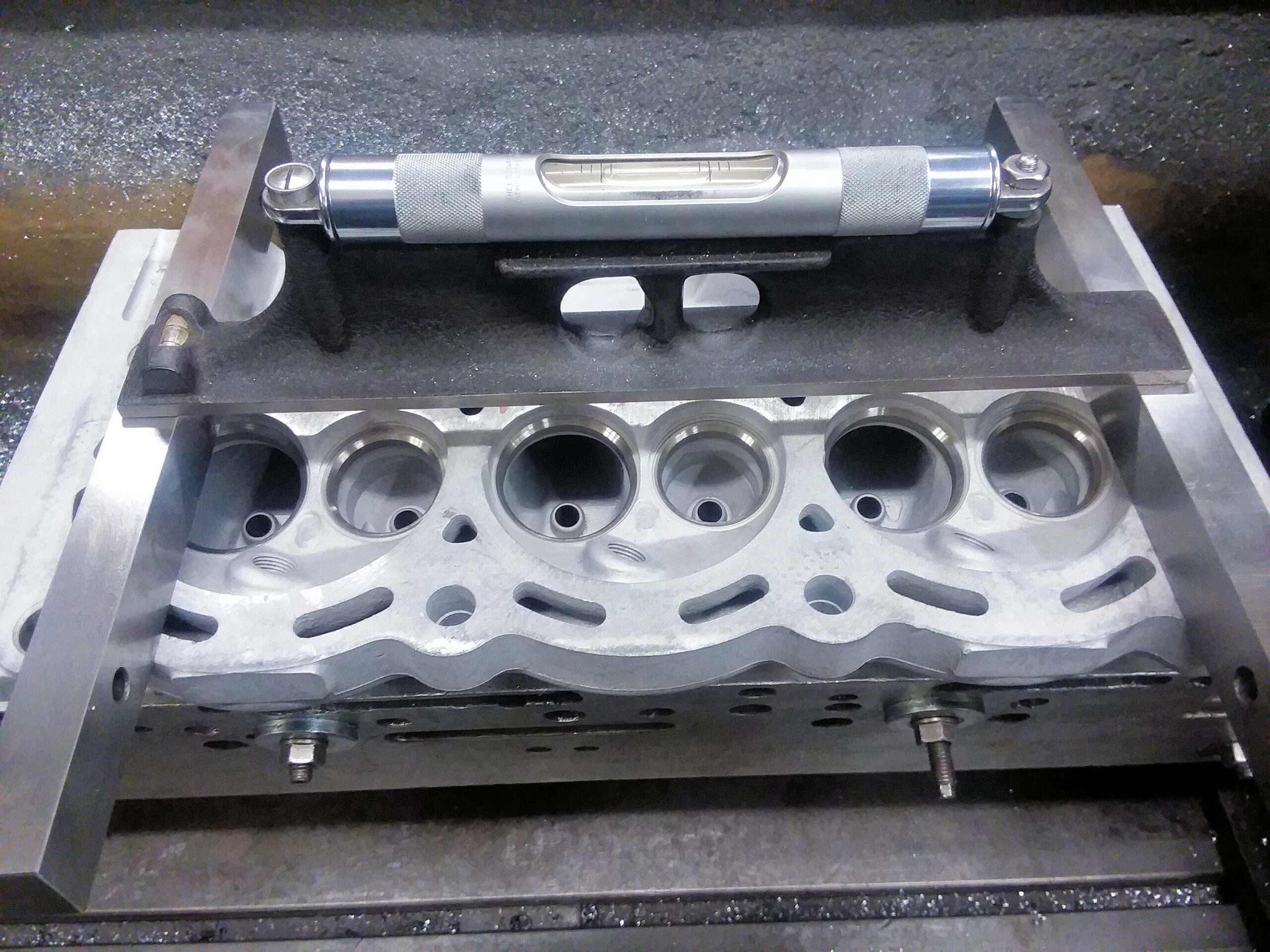

Leveling a head on our surfacing machines can test our patience at times. We are placing a perfectly flat level on a surface that may be anything but flat. Sometimes the solution for a really twisted head is to place precision parallels on each end of the head and...

by Donnie Hurt | Feb 1, 2019 | CRANKSHAFTS & CONNECTING RODS

Crankshaft end play is important to check in all engine builds. You want to make sure there is no pressure or binding at the flange of the thrust bearing. On these John Deere applications the end play needs to be checked once the engine is installed, as well as during...